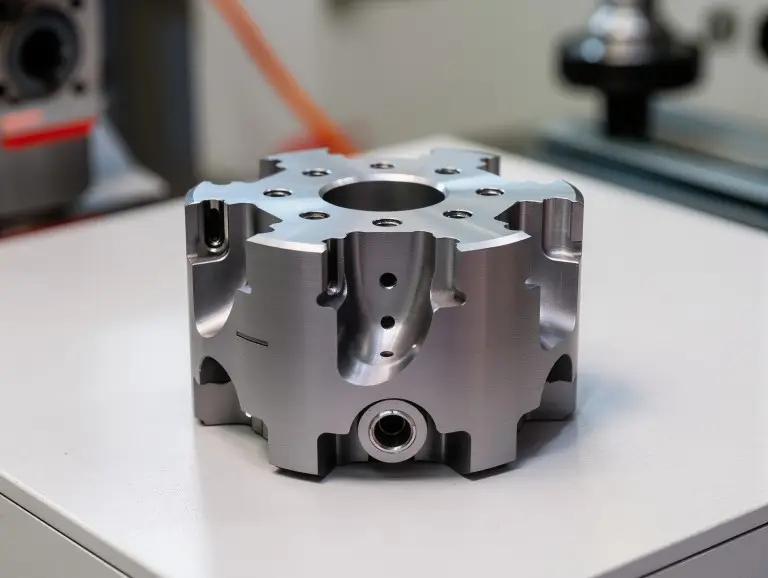

CNC Milling Service

Yonglihao Machinery provides professional CNC milling services with over 50 machining options for engineering-grade materials like metals and plastics. We offer 14 finishing options and tolerances as tight as ±0.01″. This service is ideal for rapid prototyping and part production

- Tight tolerances of ± ±0.01 mm

- 3, 4, 5-axis milling

- Multiple materials

- Complex geometries

Home » CNC Machining Service » CNC Milling Service

Type of CNC milling machine services

CNC machining services use specialized tools to cut rough workpieces into finished parts and products. These systems typically operate on three linear axes—X, Y, and Z—allowing precise cutting in both horizontal and vertical planes. This makes them perfect for machining complex geometries, such as curves, surfaces, and concave or convex planes.

At Yonglihao Machinery, we offer CNC machining services with 3-axis, 4-axis, and 5-axis options to handle parts of varying complexity. This service is suitable for both high-volume production and small, customized projects. It is widely used across the manufacturing industry.

3 Axis CNC Milling

3 axis CNC milling uses three axes - X, Y, and Z - for simple flat surface machining and drilling. This process is efficient and cost-effective and is ideal for machining flat parts and basic contours.

4 Axis CNC Milling

4 axis CNC milling adds a rotary axis that allows the workpiece to be rotated during machining to machine more complex geometries. It is suitable for parts that need to be machined at multiple angles, such as spiraled parts and complex curved surfaces.

5 Axis CNC Milling

5 axis CNC milling offers five degrees of freedom of movement, enabling precise machining of highly complex parts. It is particularly suited to critical components in aerospace, automotive, and medical devices, and is capable of machining multiple surfaces in a single clamping, greatly increasing productivity.

CNC milling tolerances

Extremely tight tolerances can be achieved through our precision CNC programming and state-of-the-art machine tool equipment, ensuring that every part meets design specifications.

| 3-Axis | 4-Axis | 5-Axis | |

| Maximum Part Size | 1000 x 500 x 500 mm | 1000 x 500 x 500 mm | 4000×1500×600 mm |

| Minimum Part Size | 5 x 5 x 5 mm | 5 x 5 x 5 mm | 5 x 5 x 5 mm |

| General Tolerances | ±0.1 mm | ±0.1 mm | ±0.05 mm |

| Lead Time | Delivery of simple parts can be as fast as 1 day. | 5 bussiness days for most projects. | 5 bussiness days for most projects. |

Note:General tolerances for CNC milling are ±0.1 mm for 3-axis and 4-axis machining, and ±0.05 mm for 5-axis machining. For high-precision parts, tolerances as tight as ±0.01 mm can be achieved upon request.

CNC milling material

Our CNC milling services support a wide range of materials, meeting the diverse needs of our customers. This flexibility ensures high-quality CNC part production.

metal milling services

Plastics milling services

Aluminium is a lightweight metal with good strength, electrical conductivity and rust resistance. This makes it great for industries like aerospace, automotive, electronics, construction, and packaging.

Grades

6061 Aluminium alloy: Good strength and corrosion resistance. Suitable for applications where these qualities are important.

7075 Aluminium alloy: A high strength alloy, mainly used in aerospace applications. Its corrosion resistance is slightly lower than 6061.

2024 Aluminium alloy: Known for its fatigue resistance, mainly used for aircraft parts and fasteners.

5052 Aluminium alloy: Good corrosion resistance and easy to weld. Commonly used in ships and chemical equipment.

3003 Aluminium alloy: easy to form, but low strength. Commonly used for storage tanks and pipes.

Surface treatment options: anodising, chemical nickel plating, electrophoretic coating, powder coating, sand blasting, polishing.

Brass is strong, easy to machine and corrosion resistant. It is ideal for CNC machining and can be used to make many mechanical parts and decorative items.

Grades

C260: Made from approximately 70% copper and 30% zinc, it is strong and easy to machine. Commonly used for stamped parts, screws and nuts.

C360: This grade has a higher lead content and is ideal for CNC machining. Often used to make high-precision parts for automated machines.

Finish Options: Plated, brushed, polished, oxidised, passivated, painted.

Copper has excellent electrical and thermal conductivity and is an ideal processing material for electrical, electronic, construction, and refrigeration equipment.

Grades

C110: Made of 99.9% copper, it has excellent electrical conductivity. It’s ideal for electrical parts, wires, contacts, and heat exchangers.

C101: This grade has even more copper than C110, offering better conductivity for high-performance electrical and electronic uses.

C122: Contains a small amount of beryllium, giving it high strength and flexibility. It’s great for springs, connectors, wear parts, and molds due to its corrosion and fatigue resistance.

C17500/C17510: These alloys have better electrical conductivity and fatigue resistance. They are strong and often used to make welding electrodes and springs for electrical switches.

Surface Finishing Options: Electroplated, Polished, Passivated, Oxidised, Painted, Chemically Plated.

Stainless steel offers excellent corrosion resistance and strength, as well as aesthetic appeal, making it ideal for processing medical devices, food processing equipment, aerospace parts, chemical equipment and architectural finishes.

Grades

304 Stainless Steel: Good rust resistance and easy to process. Widely used in kitchen equipment, building decoration and chemical equipment.

316 Stainless Steel: Provides better rust resistance, especially in salt-containing environments. It is well suited for marine equipment, chemical containers and components exposed to highly corrosive environments.

303 Stainless Steel: Easier to work with than 304, it is ideal for parts that need to be machined quickly, such as screws, bolts and valve components.

430 Stainless Steel: Good corrosion resistance and magnetic properties. Commonly used for electrical components, decorative materials and automotive trim.

410 Stainless Steel: Known for its hardness and wear resistance, but with lower corrosion resistance. It is ideal for knives, bearings and valves.

17-4PH Stainless Steel: Very strong and corrosion resistant, ideal for high strength parts in aerospace, chemical and marine applications.

Alloy steel is strong, tough, resistant to wear and corrosion. It is ideal for the manufacture of tools, machine parts and structural components.

Grades

4140 Alloy Steel: Strong and wear-resistant, used for shafts, gears, bolts and tools.

4340 Alloy Steel: Known for its toughness and fatigue strength, it is commonly used for aerospace parts, heavy machinery and tools.

8620 Alloy Steel: Ideal for carburising, making parts such as gears and bearings robust and wear-resistant.

Finish options: plated, oxidised, sandblasted, painted.

Mild steel is easy to machine, weld and form, while being strong enough to meet many structural needs. It is widely used in the engineering, automotive and construction industries.

Grades

A36 steel: easy to weld and machine, commonly used in building structures and bridges.

1018 Steel: Strong and easy to machine, commonly used for bolts, shafts, pins and screws.

1045 Steel: Higher strength and hardness, suitable for parts that require hardness, such as gears, shafts and couplings.

Surface finish options: heat treated, plated, sandblasted, painted, hot dip galvanised.

Conventional colors:Black, white, gray, natural (yellowish)

Surface Finish:Polished, Painted, Plated

POM is widely used in CNC machining because of its high strength, low friction, and dimensional stability. It’s commonly used for gears, bearings, and other machine parts.

Regular Color: Black, White, Natural (Ivory)

Surface Finish:Polished

Regular Color:Black, White, Natural (Beige)

Surface Finish:Polished, Painted, Reinforced Coating

Regular colors: transparent, black, white, natural (yellowish)

Surface Finish: Polished, Coated, Painted

Regular Color:Natural (light brown)

Surface Finish:Polished, Coated

Regular color:black, white, natural (translucent)

Surface Finish:Spraying

PE materials are often used in CNC machining to manufacture corrosion-resistant parts, sliding parts and low-cost prototypes such as pipe fittings, containers and mechanical gaskets due to their good chemical stability, low friction coefficient and easy processing.

Conventional colours: white, black, natural color (translucent or milky white)

Surface treatment: polishing, texturing, spraying

PMMA is known for its high transparency, excellent optical properties and good weather resistance. It is widely used in CNC machining to manufacture display racks, lampshades, optical lenses and decorative panels.

Conventional colours: transparent, black, white, color (customizable)

Surface treatment: polishing, laser engraving, painting, silk screen printing

Surface Finishes for CNC Milling

Yonglihao have many surface finishing options to meet different needs. These options enhance part appearance, texture, and performance. We use advanced CNC milling technology to create custom solutions. Our specialized surface treatments ensure perfection for our customers.

Workpieces are left with natural tool marks and roughness. Ideal for applications that do not require a special look or additional machining.

Higher accuracy and smoother surfaces for precision machinery, optical instruments and medical device parts.

Smooth and shiny polished surfaces for decorative parts, medical devices and high precision equipment.

Cleaning and polishing of the surface to achieve a matt and smooth effect.

After sandblasting and polishing, the parts are anodised to obtain a thick coating with high abrasion resistance, increasing hardness and durability, especially for aluminium parts that require extra strength.

The surface is bead blasted to a matt finish and then anodised for better corrosion and abrasion resistance. Available in various colours, commonly used for aluminium parts.

A black coating applied to steel and stainless steel to prevent corrosion and improve appearance. Commonly used for automotive, mechanical and decorative parts.

A robust, wear-resistant coating applied by electrostatic spraying. Available in glossy and matt colours, it is similar to paint and is used on furniture, metal products and automotive parts.

Adds a protective layer to aluminium or zinc alloys to improve corrosion resistance and electrical conductivity. Used in aerospace, electronics and automotive parts.

Plating a thin layer of metal to improve corrosion resistance, abrasion resistance or electrical conductivity, and to improve appearance.

Adds texture to the surface of a metal part to give it a metallic feel. Commonly used in household appliances and decoration.

A process that smooths parts by using abrasives to remove burrs and sharp edges, improving surface finish

Various industrial applications

Our custom CNC milling services are suitable for a wide variety of industrial applications across a broad range of industries and sectors. Whether you are in the aerospace, automotive, medical, electronics, energy or other sectors, we can provide high quality CNC milling solutions.

Advantages of CNC Milling

CNC milling has several advantages that make it an efficient and accurate machining method commonly used in modern manufacturing. Here are some of the main advantages

High Precision: CNC milling can achieve highly accurate machining and meet the strict requirements of geometric dimensions and tolerances of parts.

High efficiency: CNC milling can achieve automation and high efficiency production through computer control.

Flexibility: CNC milling is suitable for the production of various shapes and sizes of parts, and can flexibly cut different types of materials to meet diversified manufacturing needs.

Multi-axis control: CNC milling machines have multi-axis control, which allows the tool to be moved in different directions at the same time to achieve more complex machining operations, such as five-axis milling.

Accurate Repeatability: CNC milling provides highly accurate repeatability, ensuring consistent quality from part to part in high-volume production.

Versatility: CNC milling is applicable to a wide range of different industries, including aerospace, automotive, electronics, medical devices and more.

Material savings: By optimising cutting paths and toolpaths, CNC milling minimises material waste and improves material utilisation.

Rapid change of machining tasks: Once a CNC programme has been written to suit different parts, it can be quickly switched between different production tasks, enabling rapid production changes.

Why Choose Our CNC Milling Machining Service?

Yonglihao Machinery is dedicated to manufacturing products that are customized. These products are made to meet the needs of a wide variety of projects. We guarantee precise and consistent quality control for simple or complex parts.

Customized Solutions

We are committed to providing our customers with customized CNC milling solutions. We can customize our products from material selection to surface treatments.

Strict Quality Control

We enforce strict quality control processes to meet customer standards.Each part is checked to ensure it meets requirements and standards.

Fast Delivery Time

Our customers value project time. So, we provide fast CNC milling services. We promise to complete orders quickly. This ensures on-time delivery for our clients' projects.

Strict Tolerance Control

During the CNC milling process, we enforce strict tolerance control. This guarantees the accuracy of every part, down to ±0.01 millimeters. We meet high standards for part quality and consistency in various industries.

FAQ

We support a wide range of materials, including metals like aluminum, brass, copper, stainless steel, alloy steel, and mild steel, as well as plastics such as ABS, POM, Nylon (PA), PC, PEEK, PP, PE, and PMMA. This ensures we can meet diverse customer needs.

Our CNC milling services offer general tolerances of ±0.1 mm for 3-axis and 4-axis machining, and ±0.05 mm for 5-axis machining. For high-precision applications, we can achieve tolerances as tight as ±0.01 mm.

We offer fast turnaround times. Simple parts can be delivered in as little as 7 day, while most projects are completed within 10 business days. We prioritize on-time delivery to keep your projects on schedule.

Yes, we provide fully customized CNC milling solutions. From material selection to surface treatments, we tailor every aspect of the process to meet your specific requirements.

Absolutely! With 3-axis, 4-axis, and 5-axis CNC milling capabilities, we can machine complex geometries, including curved surfaces, spiraled parts, and multi-surface components.

We follow strict quality control processes. Every part is thoroughly inspected to ensure it meets your design specifications and industry standards. Our advanced equipment and skilled team guarantee consistent, high-quality results.

Yes, we support both high-volume production and small-batch custom machining. This flexibility allows us to cater to projects of all sizes.