Painting Services

Yonglihao Machinery offers zinc plating services to enhance corrosion resistance and improve the appearance of metal parts. This process is widely used for fasteners and production components where rust protection, stable assembly performance, and cost control are essential.

- Bright, uniform metallic finish

- Improved assembly performance for fasteners and hardware

- Optional passivation for enhanced corrosion resistance

Home » Surface Finishing Service » Painting Services

What Is Zinc Plating?

Zinc plating is an electrochemical finishing process that deposits a controlled layer of zinc onto a metal surface. This zinc layer acts as a protective barrier, reducing the risk of rust in normal service environments.

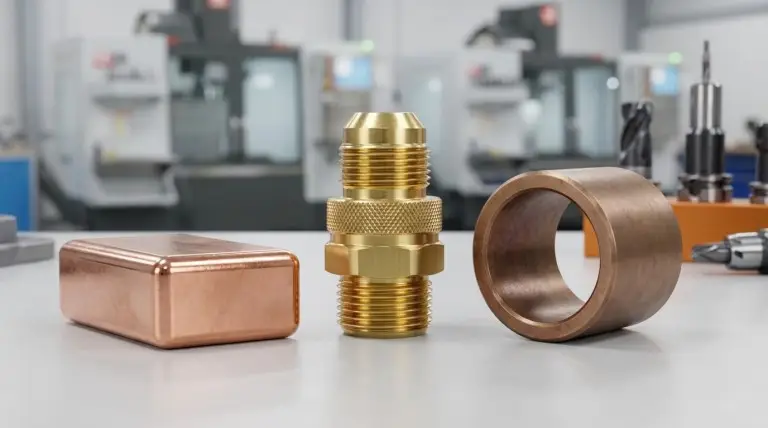

Zinc plating is most commonly applied to steel and steel alloys. It can also be used on copper alloys and aluminum with proper pretreatment (subject to review). The final thickness, appearance, and performance depend on the base material, surface preparation, geometry, and the required salt-spray or corrosion target.

One-Stop Manufacturing

We can perform zinc plating as a downstream step for parts made through:

Surface Preparation & Final Appearance

Zinc plating follows the base surface condition. Deep scratches, dents, pits, and heavy tool marks will remain visible unless additional smoothing is done before plating.

For fit-critical parts, plating thickness must be specified. Threads, tight bores, and sealing faces may require masking or controlled thickness to prevent assembly issues.

| Surface Preparation | Applicable Materials | Typical Thickness | Visual Appearance | Notes |

|---|---|---|---|---|

| Cleaned / smoothed as required | Steel (most common), copper alloys, aluminum (pretreatment by review) | Defined per RFQ | Bright metallic zinc finish | Passivation improves corrosion resistance; appearance varies by spec |

FAQ

What materials can be zinc plated?

Most commonly steel and steel alloys. Copper alloys and aluminum are reviewed based on pretreatment needs.

Does zinc plating prevent rust?

Yes, it significantly improves corrosion resistance. Performance depends on thickness and post-treatment.

Will zinc plating change dimensions?

Yes, it adds thickness. Tight fits and threads should be specified and may need masking.

Can you provide passivation after zinc plating?

Yes, passivation is commonly used to enhance corrosion resistance and stability.

Will scratches still be visible after plating?

Yes, plating follows the base surface. Cosmetic parts may need pre-polishing.

Can you mask threads and sealing faces?

Yes, mark these areas clearly on the drawing or RFQ notes.

What do you need for a fast quote?

We need the material grade, quantity, part size, thickness requirement, corrosion target, critical fits/masking areas, and lead time.