Can complex metal parts be made with precision and speed? Yes, they can, thanks to transfer die stamping. Transfer die stamping is a key process for making complex metal parts. It uses a multi-station die to shape sheet metal into three-dimensional parts. This advanced metal forming method is used by top companies like Yonglihao Machinery.

We focus on metal processing, offering top-notch solutions. This method moves the workpiece between dies, making it precise and efficient. Our team’s expertise helps us provide excellent transfer die stamping solutions for many industries.

Table of Contents

Understanding Transfer Die Stamping

At the core of metal processing is transfer die stamping. It’s a precise way to shape complex parts. This method is key for making high-quality metal components efficiently.

Definition and Basic Principles

Transfer die stamping is a precise metalworking method. It moves a metal strip or sheet through stations to shape and cut it. Each station does a specific task, like cutting or bending, to finish the part.

This process uses multiple dies for different operations. By moving the material between stations it creates intricate shapes with tight tolerances.

Historical Development in Metal Processing

The history of transfer die stamping is marked by significant growth. It started as a solution to earlier metal forming limits, especially for complex parts.

Advances in automation and control systems have made it more precise. Now, it can produce complex metal parts with high precision and consistency.

Ready to get started on your next project? Get a personalized estimate for your parts machining needs.

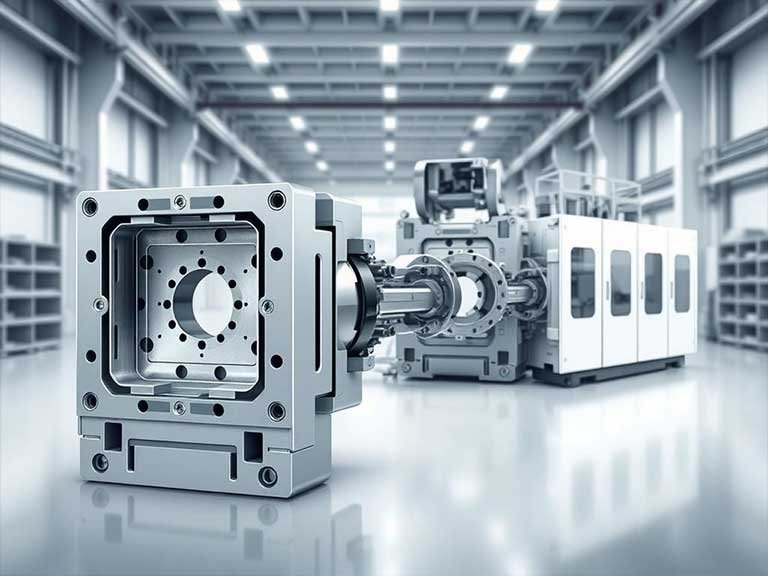

Key Components of Transfer Die Stamping Systems

The success of transfer die stamping systems depends on several key components. We’ll look at the essential parts of a complete system and how they work together.

The Transfer Die Structure

The transfer die is a multi-station die that does many operations at once. It’s designed to handle the stamping forces, with careful design and material choice. We’ll explore how these dies are built to last.

Press Machines Used in Transfer Die Stamping

Press machines are crucial for the stamping process, providing the needed force. There are mechanical, hydraulic, and servo presses, each with its own benefits. We’ll discuss how to choose the right press machine for the job.

Transfer Mechanisms and Automation Systems

Transfer mechanisms and automation systems are vital in modern transfer die stamping. They include gripper systems and transfer bars that move workpieces between stations. Automation systems, like PLCs and sensors, ensure precision and consistency.

Understanding these components shows the complexity and efficiency of transfer die stamping systems. Each part is essential for achieving high precision and efficiency.

The Transfer Die Stamping Process Explained

Transfer die stamping involves precise operations for making complex metal parts. It’s key in many manufacturing fields where precision and efficiency are crucial. We’ll explain how transfer die stamping works, from preparing the material to the final quality checks.

Material Preparation and Feeding

The first step in transfer die stamping is preparing and feeding materials. We pick the right metals and thicknesses for each part. Then, we unwind and feed the metal coil into the press.

Advanced systems help deliver the material to the first station of the die. This ensures everything goes smoothly from the start.

Stamping Operations and Sequences

The stamping process includes steps like blanking, piercing, forming, drawing, and trimming. Each step happens at a different station. The workpiece moves from one station to the next using special fingers or grippers.

This mechanism moves in the x, y, and sometimes z axes. It makes sure the workpiece is always in the right place.

| Operation | Description | Station |

| Blanking | Cutting out the initial blank from the metal sheet | 1 |

| Piercing | Creating holes or other features in the blank | 2 |

| Forming | Shaping the blank into the desired form | 3 |

| Trimming | Removing excess material from the formed part | 4 |

Part Ejection and Quality Control

After the last step, the part is ejected from the die. Quality control is key in this process. We use in-line inspection and statistical process control to check parts.

Regular maintenance and setup of the dies are also important. They help keep the process running smoothly and parts of high quality.

Transfer Die Stamping Works and Used For

Transfer die stamping is vital in many industries. It’s used to make a wide range of parts across different sectors.

Common Applications Across Industries

This technique is used in the automotive, aerospace, medical devices, electronics, and houseware industries. In the automotive sector, it helps make complex parts like cylinder heads and seat frames.

The aerospace industry uses it for lightweight yet strong components. Consumer electronics and medical devices also benefit from it for making precise parts.

| Industry | Common Applications |

| Automotive | Cylinder heads, brackets, pump housings, brake calipers, seat frames |

| Aerospace | Lightweight structural components, precision parts |

| Medical Devices | Intricate parts, surgical instruments, and device components |

Types of Parts Best Suited for Transfer Die Stamping

Transfer die stamping is great for parts with tricky shapes and those needing many forming steps. It’s also good for parts that need special material flow. Our team at Yonglihao Machinery checks part designs to see if transfer die stamping is the best choice.

| Part Characteristics | Benefits of Transfer Die Stamping |

| Complex geometries | Precise formation of intricate shapes |

| Multiple forming operations | Efficient production in a single process |

| Specific material flow requirements | Controlled material flow for optimal part quality |

Advantages of Transfer Die Stamping

Transfer die stamping is known for its efficiency, precision, and cost savings. It’s a key method in many industries for making high-quality metal parts.

Production Efficiency and Speed

Transfer die stamping is fast and efficient. It automates part transfer and performs operations at multiple stations at once. This cuts down production time, especially for complex parts.

Precision and Consistency Benefits

Transfer die stamping produces parts with high accuracy and consistent quality. It reduces damage risk and allows for quality checks at each stage. This ensures top-notch final products.

Cost-Effectiveness for Complex Parts

While transfer dies cost a lot upfront, they save money for large orders. The cost per part goes down as you make more. This makes transfer die stamping a smart choice for complex parts.

Comparing Transfer Die Stamping with Other Methods

Understanding the differences between metal stamping methods is key. Transfer die stamping is one of these methods. It has its own strengths and weaknesses compared to others.

Transfer Die vs. Progressive Die Stamping

Transfer die and progressive die stamping both make complex metal parts. The main difference is how the material moves. Progressive die uses a continuous strip, while a transfer die moves individual parts.

Transfer die stamping is better for parts with complex shapes or deep draws. It’s more flexible and can handle parts that a progressive die can’t.

Transfer Die vs. Simple and Compound Dies

Simple and compound dies are for simpler stamping jobs. Transfer die stamping does more operations in one go. This makes it better for complex parts and big orders.

Comparing Transfer Die Stamping with Other Metal Forming Methods

Transfer die stamping is a top choice for making complex metal parts. It’s compared to other methods like progressive die stamping and simple/compound dies. Each method has its own strengths and weaknesses.

Let’s look at how they compare:

| Process | Complexity Handling | Production Volume | Operational Flexibility |

| Transfer Die Stamping | High | High | High |

| Progressive Die Stamping | Medium | High | Medium |

| Simple/Compound Dies | Low | Low-Medium | Low |

Press-to-Press Transfer vs. Transfer Die Systems

Press-to-press transfer systems move parts between presses, needing more space and possibly more money. Transfer die systems do many steps in one press, saving space and maybe money. The best choice depends on how much you make, how complex the parts are, and what you can afford.

Knowing the differences helps manufacturers pick the best method for their needs. They balance part complexity, how much they make, and the costs.

Challenges and Solutions in Transfer Die Stamping

Transfer die stamping is great for complex metal parts but faces challenges. We need to solve these to make production efficient and high-quality.

Precision and Tolerance Control

Keeping parts precise is key, especially for complex ones. We use advanced dies and careful process planning. With tech like CAD and CAM, we get better precision and accuracy.

Material Utilization Efficiency

Using materials wisely is important for cost and the environment. We use smart sheet metal design to reduce waste. This makes production more sustainable and cheaper.

Tooling Longevity and Maintenance

Wear and upkeep of tools are big issues. We design and maintain dies well to make them last longer. This cuts downtime and boosts equipment efficiency.

We tackle these problems with smart solutions. We use the latest tech, optimize processes, and keep high standards in tooling and maintenance.

Selecting the Right Transfer Die Stamping Solution

Finding the right transfer die stamping solution is key for manufacturers. At Yonglihao Machinery, we’re here to help with top-notch solutions.

Factors to Consider When Choosing Transfer Die Stamping

Choosing transfer die stamping for custom parts involves several key factors. These include part complexity, material, and how much you make.

- Complexity of Parts: It’s great for complex designs and tight tolerances. It’s perfect for parts needing many operations and detailed designs.

- Material Choice: Different materials need special stamping care. Knowing material properties is crucial.

- Production Volume: It works well for making medium to high volumes. It’s efficient and quick.

Conclusion

Transfer die stamping is a game-changer for modern manufacturing. It’s super efficient at making complex parts with great precision. This makes it a top choice for many industries.

This method can do many tasks at once, making it faster and cheaper. It’s especially good for making intricate metal parts. This is why it’s a favorite for industries that need detailed metal components.

At Yonglihao Machinery, we’ve been in the metal processing business since 2010. We offer services like transfer die stamping, CNC machining, and laser cutting services. Our team is all about quality and making sure our clients get what they need.

As manufacturing keeps getting better, so will transfer die stamping. We invite businesses to talk to us about how it can help them. We’re here to make your production better. In addition, we’re all about precision and quality in metal processing. We’re a trusted partner in the manufacturing world. Count on us for top-notch services.

FAQ

What is the primary advantage of using transfer die stamping over progressive die stamping?

Transfer die stamping is way more flexible and precise for complex parts. It can do many operations on one part with great accuracy.

How does transfer die stamping improve production efficiency?

It makes production faster by doing many tasks at once. This means less time and more parts made, perfect for big orders.

What types of parts are best suited for transfer die stamping?

It’s great for complex parts with lots of features. This is why it’s a hit in the automotive and aerospace fields for its precision and consistency.

How does automation enhance the transfer die stamping process?

Automation makes the process smoother and more consistent. It helps with handling parts and cuts down on labor costs.

What are the key considerations when selecting a transfer die stamping solution?

When picking a solution, think about part complexity, material needs, how many parts you’ll make, and quality standards. These are all important.