Surface Finishing Service

At Yonglihao Machinery, I offer surface finishing services that enhance corrosion resistance, wear performance, appearance, and coating stability. Whether you need a thin functional layer, a premium cosmetic texture, or a durable protective coating, I help you select the right finish based on your part’s geometry, material, and service environment.

- Tailored recommendations based on application and material

- Achieving texture, color targets, and flawless visible surfaces

- From fabrication to finishing, all in one place

Home » Surface Finishing Service

Engineering-led recommendations

I review your drawings, materials, service conditions, and fit-critical features. Then, I recommend a finish route that minimizes errors and reduces rework

Consistent, repeatable results

I control surface preparation, masking, and inspections to ensure consistent texture, color, and fit across prototypes and repeat orders

One-stop responsibility

I integrate finishing into the build process, reducing handoffs and ensuring clear ownership for predictable delivery

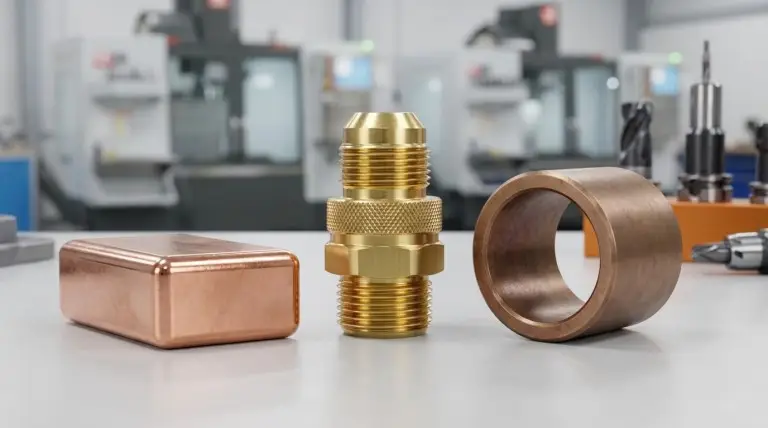

Surface Finishing Capabilities

Choose a surface finishing solution that meets your needs. We offer a variety of finishing options.

If you can’t find the surface treatment process you need, you can send me your drawings, and I will recommend a compatible surface treatment process.

Industries We Support

Different industries have unique surface requirements. I match finishes to your specific needs—corrosion resistance, wear zones, cleanliness, appearance, and fit-critical features—so your parts perform as expected and assemble without issues.

Quality & Inspection Approach

I treat finishing as a controlled manufacturing step, not an afterthought. Depending on your part and process, I align inspections with clear, measurable criteria.

- Appearance checks: Coverage, texture consistency, and shade range.

- Fit-sensitive interfaces: Masking verification for seal faces, threads, and contact pads.

- Thickness requirements: Defined per RFQ for coatings and plating to ensure proper assembly.

- Repeat-order traceability: Documented RFQ notes and finish callouts for consistent results across batches.

Include any drawing notes, test methods, or customer standards in your RFQ to ensure I meet your expectations.

FAQ

Material grade, quantity, part size, target finish, cosmetic expectations, critical fits, masking areas, and lead time.

Plating and coatings (nickel, zinc, powder coating, painting) add thickness. Define fit-critical areas and no-coat zones.

Chromate Conversion Coating, Passivation, and Black Oxide are ideal for minimal dimensional change.

Yes. Mark these areas clearly on your drawing or RFQ notes.

It depends on the base metal and environment: Passivation for stainless, Chromate Conversion for aluminum, plated/coated systems for harsher exposure, and Powder/Paint for barrier protection.

Plating supports conductivity, while anodizing is insulating. Specify contact resistance requirements to define masking zones.

I align surface preparation, define texture targets, and confirm colors by code or sample approval.

Yes. I support finishing for parts made by CNC machining, laser cutting, bending, stamping, welding, casting, and wire EDM.

Yes. I manage prototypes, first-article builds, and repeat production with clear finish callouts.