Metal stamping is a method of manufacturing complex stamping parts and components from flat metal sheets. Industries that rely on precision engineering need to understand all the different types of metal stamping and how they are used. A metal stamping press is a processing machine that uses special tools and dies to shape and cut sheet metal.

There are four main types of metal stamping: progressive die stamping, compound stamping, transfer die stamping, and four-slide stamping. the different processes all have different benefits and are suited to the production of metal-fabricated parts for different needs.

Four Types of Metal Stamping

Progressive Die Stamping

Progressive die stamping is a high-volume manufacturing method. A strip of metal taken from a coil is automatically passed through multiple forming dies. Each die processes the blank to bring the part closer to its final shape.

When the material reaches its final stop, the finished product is separated from the metal strip. At the same time, a new sheet of metal enters the starting end of the progressive die for the first pass. By pushing guide pins into locating holes at each die station, the progressive die makes the same part every time.

Compound Stamping

Compound stamping is a method of making simple flat metal parts such as washers. It can also make complex parts with smaller tolerances, such as seals, fixtures, shields, baffles, frames, etc.

It can do more cutting, punching, and bending in one pass than other stamping methods. This makes it cost-effective for medium to high-volume production. Speed varies depending on part size.

It is well suited for the rapid manufacture of simple parts with high repeatability, but may not work well for complex patterns. In this case, progressive stamping will work better.

Transfer Die Stamping

Transfer Die Stamping is a type of metal stamping where each part is treated as a separate unit. The machine first separates the part from the metal strip. The part is then moved to a different location and processed in a different way.

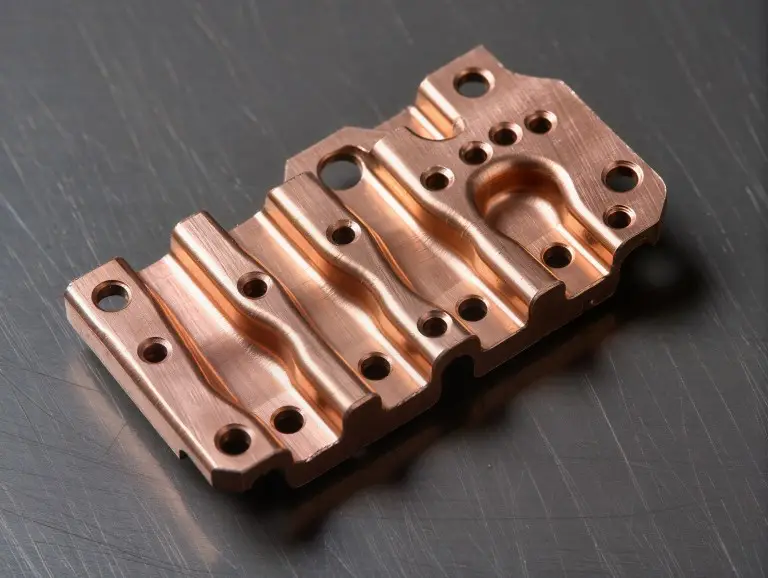

This is the best way to make parts with lots of small details like knurling, ribs, and threads. It’s perfect for making tubular applications and deep-drawn parts in metals such as copper, brass, aluminum, and stainless steel.

In addition to these features, transfer die stamping has some other important advantages. It is very effective and cost-effective for small production runs as it is the best method for making large parts.

Different surface finishes can be obtained using this method, and since different dies are used, there is no need for plate guides or lifters. In addition, the use of one or more dies usually reduces tooling costs, making it ideal for many metal stamping projects.

Four-slide Stamping

In contrast to metal stamping presses that use vertical stamping, four-slide stamping uses four horizontally moving sliders that move by means of gears and shafts that are connected together.

These sliders strike the workpiece at right angles, thus ensuring the correct and consistent shape of the metal. Many different fields use this method to create complex and precise parts, such as the aerospace, electronics, and automotive industries.

What Types of Metal Stamping Presses Are Available?

Here are a few different types of metal stamping presses.

Mechanical presses

These machines have a motor that is connected to a flywheel mechanism. They can make parts quickly, making them ideal for making simple, shallow-shaped parts.

They are typically used for progressive and transfer stamping to make parts for automobiles, appliances, and tools.

Hydraulic Presses

These presses are not as fast as mechanical presses but are more flexible. Because the die space, pressure, and stroke length can be changed. They can be used to make deep and complex things like tanks, cylinders, and bowls.

Mechanical servo presses

These presses are as fast as mechanical presses but can be bent in different ways like hydraulic presses. They can be fine-tuned for speed, stroke, position, and slide movement, so they can be used for a variety of molds, part types, and output speeds.

Pneumatic Presses

Popular in binderies, pneumatic presses use compressed air to perform mechanical tasks such as cutting and bending. Compared to hydraulic presses, pneumatic presses work faster and cleaner. Fully pneumatic machines do not use any power source other than compressed air. The operator places the material, starts the pressing process, and then gets the final part.

Things to Consider When Choosing the Metal Stamping Process

Choosing the Right Material

The type of material you choose will affect not only the function of the part but also the stamping method. You need to consider factors such as the strength, flexibility, and rust resistance of the material. You should consider whether the material can withstand the stress of the stamping process. How will it behave under load when it is put into use? Choosing the right material is the first condition for ensuring that the stamped part will work properly.

Precision

Precision is not only a term used in metal stamping but also a rule that must be followed. It is important to know how much tolerance your plan requires. If the tolerance is too tight, the cost will rise. Therefore, a balance must be found between precision and practicality. Consider what the stamping process can do and what tools you will use. Too tight a tolerance is just as bad as an insufficient tolerance.

Complexity and Feasibility

A complex pattern may look great on paper. But can it be manufactured using the metal stamping process? Consider the limitations of the stamping process. Can your plan be achieved without compromising integrity? Simplifying the design or breaking it down into several parts may be the key to making the design look realistic.

Cost-effectiveness

When it comes to metal stamping, efficiency and cost-effectiveness go hand in hand. Think about how many steps are needed to manufacture a part. If there are many steps and the part is complex, the cost will increase. Try to make the design simpler without compromising on quality. Remember that a simpler process usually means lower costs.

Equipment and Tools

The available stamping tools and equipment must match your design. Of course, you can have the tools custom-made, but this will be more expensive. It is therefore cheaper to adapt the design to the existing tools. Work with your experts and the tool manufacturer to find the best solution.

Prototyping

Prototype samples are made before mass production begins. When you test the samples, you may discover errors in the design. These errors are not visible on the computer screen. This is a very important step to ensure that your parts will work properly in real life.

What Safety Issues Should I Be Aware of When Using a Metal Stamping Press?

Metal fabrication methods that use moving parts, sharp metal edges, and squeezing forces can be dangerous to workers. These include electric shocks, pinch points, noise, and moving objects.

Those performing hazardous work should always wear the correct personal protective equipment (PPE), such as safety shoes, goggles, gloves, and ears. When using metal stamping tools, safety must come first. An important factor in preventing personnel injuries is operator education.