Cold chamber die casting is the right choice when your alloy and quality goals require high-pressure filling. This process gives you strict control of temperature, packing, and porosity. At Yonglihao Machinery, we use this guide to help buyers and engineers. It helps them quickly decide if CCD is the right process for their part and what drives success. You will learn the core definition and the step-by-step cycle. We will also cover the machine parts that control results. Finally, we will show a practical way to compare cold vs. hot chamber options. We will focus on what matters on the shop floor: process windows, selection rules, and preventing defects.

What Is Cold Chamber Die Casting?

Cold chamber die casting is a process where molten metal is melted in an external furnace. The metal is then ladled into a shot sleeve. From there, it is injected into a steel die under high pressure. This method produces complex metal parts with high accuracy and a good surface finish. It also ensures repeatable properties. The key difference is simple: the injection system is not always in molten metal. This helps when the alloy’s temperature or reactivity would damage hot-chamber parts.

In cold chamber die casting, molten metal is poured into a chamber. It is then injected into a die at high pressure. The process starts by melting metal in a separate furnace. The metal is then moved to the cold chamber machine. This allows for making parts with a great surface finish and exact dimensions. It is suitable for many metals, like aluminum and copper alloys. Sometimes, it is also used for magnesium alloys. This depends on the plant setup and part needs. The goal of CCD is to fill the die fast, pack it well, and control how it cools. This must be done without trapping air or letting the metal freeze too early.

|

Metal alloy |

Melting point (°C) |

Typical applications |

|---|---|---|

|

Aluminum |

660°C |

Automotive, aerospace, housings, structural parts |

|

Copper |

1085°C |

Electrical components, hardware, thermal parts |

|

Magnesium |

650°C |

Aerospace, lightweight electronics, brackets |

How the Cold Chamber Die Casting Process Works?

The cold chamber process prepares a closed die. Then, molten metal is moved into the shot sleeve and injected quickly to fill the cavity. Packing pressure is applied until the gate freezes. Finally, the solid casting is ejected. The steps below show what each stage tries to control. These are also the stages where defects often begin.

Step 1: Die Preparation and Setup

First, we prepare and set up the die. We make sure the die is clean, lubricated, and aligned. This prevents flash, sticking, and poor venting. A stable die temperature is very important here. A die that is too cold can cause cold shuts. A die that is too hot raises the risk of soldering and flash.

Step 2: Metal Melting in an External Furnace

Next, we melt the metal in an external furnace. The molten metal is then ladled into the shot sleeve of the machine. Consistent transfer is a key performance indicator. Turbulence and temperature drops during ladling can increase trapped air. This can also cause the metal to cool too soon in the shot sleeve.

Step 3: Injection, Filling, and Intensification

Once the molten metal is in the shot sleeve, we use a hydraulic plunger. It quickly forces the metal into the die cavity at high speeds. The injection phase is critical. We apply intensification pressure, often 10,000–20,000 psi. This ensures the die fills completely and reduces porosity. Think of the cycle as two jobs: “fill fast before freezing” and “pack hard before the gate freezes.”

|

Step |

Description |

Key factors |

|---|---|---|

|

1 |

Die preparation and setup |

Alignment, cleanliness, die temperature, vent condition |

|

2 |

External melting and ladling |

Melt quality, temperature control, transfer turbulence |

|

3 |

Injection and pressure application |

Fill speed, gate design, intensification (10,000–20,000 psi) |

Further Reading: How Does Metal Die Casting Work?

Key Machine Components and What They Control

A cold chamber die casting machine controls quality through several actions. It coordinates melt transfer, shot sleeve conditions, and injection speed. It also manages packing pressure, clamping force, and die cooling. If you can map a component to a variable and then to a defect, you can solve problems faster. This also helps you design better DFM checks.

- External Furnace & Ladle: External melting keeps the injection system out of the molten metal. This also creates a clearer workflow for melt quality. This includes degassing, fluxing, dross control, and consistent superheat. Poor transfer practices often lead to gas porosity or misruns later.

- Shot Sleeve: The shot sleeve is where molten metal is ladled before injection. A hydraulic plunger then pushes the metal into the mold. The sleeve fill ratio, sleeve temperature, and shot delay all affect air entrapment. They also determine if a “cold slug” forms. If metal freezes too early in the sleeve, you will get short shots and cold shuts. This happens no matter how strong your intensification is.

- Plunger & Intensification System: The plunger pushes the metal into the die cavity. It then applies intensification pressure to pack the casting as it cools. This process uses high pressure, often over 10,000 psi. It ensures the metal fills the cavity completely. Packing pressure is key to preventing shrinkage porosity. This is especially true around thick-to-thin sections and areas that freeze last.

- Die & Cooling Channels: The die creates the part’s shape. It also controls heat removal through cooling lines and thermal balance. Cooling is not just about being fast. It is about freezing the right zones at the right time. Bad thermal balance can cause warping, soldering, or porosity in the same spots.

- Clamping Unit & Ejection System: Clamping force holds the die halves together during peak pressure. If the clamp force is too low, you get flash. If it is too high, it speeds up die wear and can cause parting-line problems. Ejector pins must release the casting without bending thin walls or scratching surfaces.

Quick sizing rule (clamping force):

Clamping Force ≈ Cavity Pressure × Projected Area.

Example: If the projected area is 120 cm² and cavity pressure is 800 kg/cm², the clamping force is about 96,000 kg (≈ 96 tons).

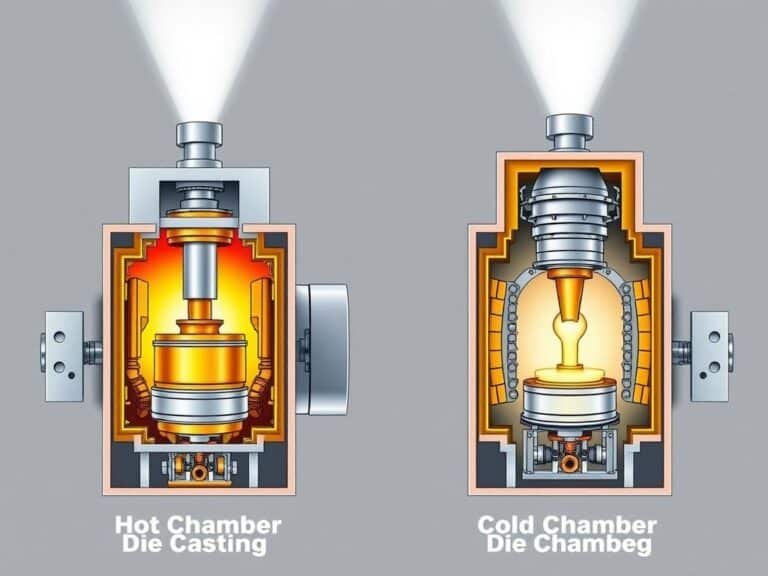

Cold Chamber vs. Hot Chamber Die Casting: When to Choose Which

Choose cold chamber when the alloy’s temperature, reactivity, or shot volume is high. These factors make a hot chamber setup inefficient or hard to maintain. Choose hot chamber when the alloy and part size allow for an integrated molten bath. This leads to faster cycles. Cold chamber often suits aluminum and many copper alloys. Hot chamber is usually for lower-melting alloys like zinc and some magnesium. The choice is not about “better vs. worse.” It is about which machine design protects quality at your target speed.

A simple selection checklist:

- Alloy temperature / harshness → favors cold chamber.

- Part size / shot weight is large → favors cold chamber.

- Highest cycle speed is the priority and alloy allows → favors hot chamber.

- Porosity target is strict (for leak-tight parts) → either can work. However, CCD often gives more control through packing and process monitoring.

Further Reading: Hot vs. Cold Chamber Die Casting

Materials for Cold Chamber Die Casting and Typical Applications

Materials for cold chamber die casting are chosen for their strength, weight, and conductivity. Corrosion resistance and the ability to fill thin walls are also important. The process can handle various alloys. This makes it a practical choice for producing parts with long service lives. The material choice and die design must be looked at together. This is because flow length, gate freeze, and shrinkage depend on the alloy.

- Aluminum Alloys: Aluminum alloys are common in cold chamber die casting. They offer an outstanding strength-to-weight ratio, corrosion resistance, and thermal conductivity. These alloys perform well in housings, brackets, and automotive parts. Thin walls can be achieved, but it is important to control flow length and ensure there is good venting and an effective overflow strategy.

- Magnesium Alloys:Magnesium alloys make it possible to produce ultra-lightweight parts with good stiffness. These materials are widely used in aerospace and portable electronics. Handling magnesium calls for strict melt protection and strong safety controls, which often determine whether CCD or hot chamber is the better option for a specific project. In cold chamber processes, transfer stability and oxidation control are especially important.

- Copper/Brass Alloys: Copper alloys, including brass and bronze, are valued for their conductivity and corrosion resistance. Cold chamber setups are common for these metals. This is because their temperatures are higher and can be tough on hot-chamber parts. These parts are often used in electrical connectors, hardware, and thermal components. Here, performance is more important than weight.

Process Optimization and Common Defects

You optimize cold chamber die casting by controlling key factors. These include temperature, shot profile, venting, and intensification timing. You then check the results with real-time monitoring and targeted inspections. Cold chamber die casting can have defects like porosity, cold shuts, and surface flaws. Most have clear “cause → fix” paths. You just need to find if the issue starts in transfer, filling, packing, or release.

|

Defect |

Typical cause |

Practical direction (cause → fix) |

|---|---|---|

|

Gas porosity |

Air entrapment, turbulent ladling, poor venting |

Reduce turbulence, improve venting/vacuum, optimize shot profile |

|

Shrinkage porosity |

Not enough packing, hot spots, late-freezing zones |

Increase/retime intensification, rebalance cooling, adjust gate |

|

Cold shut / misrun |

Metal too cold, fill too slow, gate restriction |

Raise metal/die temp, increase fill speed, improve gating/overflow |

|

Flash |

Not enough clamp force, worn die, high cavity pressure |

Check clamping force, repair parting surfaces, tune shot/pressure |

|

Sticking / soldering |

Die too hot, poor lube, alloy interaction |

Improve die temp control, lube practice, use surface treatments |

Two controls we rely on most in production:

- Shot consistency (metal temperature, sleeve condition, repeatable velocity).

- Packing discipline (intensification amount and timing matched to gate freeze).

Conclusion

Cold chamber die casting gives you precision and durability. It is great for complex parts that need high-pressure packing. This is especially true for aluminum and many copper alloys. At Yonglihao Machinery, we find that the best results come from treating CCD as a controlled system. It is not just a single “pressure number.” Transfer stability, shot sleeve conditions, and die thermal balance all matter. If you are looking at a new part, start with the basics. Check the projected area, clamp size, alloy behavior, and defect risks. Then, lock in a process window you can monitor. When those fundamentals are right, CCD becomes a predictable, scalable production method. It is no longer a trial-and-error exercise.

As a leader in prototype manufacturing, Yonglihao Machinery provides expert guidance and solutions for aluminum die casting and other cold chamber processes. We help you achieve precision, efficiency, and quality in every part.

FAQ

What is the main difference between cold chamber and hot chamber die casting?

The main difference is how molten metal is delivered to the die. Cold chamber melts metal outside the machine and ladles it into a shot sleeve. Hot chamber uses an integrated molten bath and injection system. This affects cycle speed, maintenance, and which alloys you can use.

Which metals are suitable for cold chamber die casting?

Cold chamber die casting is common for aluminum and many copper alloys. It can also be used for magnesium alloys, depending on the plant and part. The process is best when the alloy’s temperature, reactivity, or shot size makes hot-chamber use inefficient.

What intensification pressure range is typical in cold chamber die casting?

A typical intensification pressure range is 10,000–20,000 psi. The right value depends on wall thickness, gating, and porosity needs. The pressure must be timed to pack the metal before the gate freezes.

Why do cold shuts happen in cold chamber die casting?

Cold shuts happen when streams of metal cool too much and do not fuse together. Common causes are low metal or die temperature, a slow fill speed, or poor venting. Fixing the temperature and shot profile often solves the problem better than just adding pressure.

How can I estimate whether my machine has enough clamping force?

Use the basic rule: Clamping Force ≈ Cavity Pressure × Projected Area. This quick check helps prevent flash risk early on. It also shows when you might need a larger press or a different parting line strategy.