Is there a clear winner between titanium and aluminum for lightweight prototyping, or is the choice more nuanced than it appears? Choosing between titanium and aluminum for lightweight prototyping depends on several factors. Key considerations include strength, cost, and specific project requirements.

Aluminum is lighter, with a density of 2.7 g/cm³ compared to titanium’s 4.5 g/cm³. However, titanium is stronger, with a tensile strength ranging from 900 to 1200 MPa, surpassing aluminum’s 200 to 600 MPa. This difference is crucial in industries like aerospace and medical devices, where materials must perform under high-stress conditions.

Yonglihao Machinery, with over a decade of experience, has assisted clients in making these choices. Aluminum is generally cheaper, costing approximately $2.8/kg, and easier to work with, making it ideal for quick prototypes. Titanium, at about $7-8/kg, offers better corrosion resistance, making it suitable for harsh environments.

When deciding, it’s also important to consider how these materials handle heat and electricity. Aluminum has a higher thermal conductivity (150-200 W/m·K) compared to titanium (~22 W/m·K), and better electrical conductivity (approximately 60% of copper’s conductivity vs. titanium’s ~3%).

Understanding these properties helps in selecting the right material for specific applications. From aerospace parts to medical implants, the choice between titanium and aluminum depends on balancing weight, durability, and cost.

The Essential Characteristics of Titanium

Titanium stands out from aluminum with its unique properties. It offers advantages in high-performance fields. Its chemical and mechanical traits give it an edge in critical industries.

- Density: 4.506 g/cm³, which is about 42% less than steel.

- Strength-to-Weight Ratio: Superior to many metals.

- Thermal Conductivity:~22 W/m·K, lower than aluminum.

- Corrosion Resistance: Excellent due to its oxide layer.

- Melting Point: 1668°C, much higher than aluminum’s 660°C.

Chemical Composition and Alloy Types

Titanium is often alloyed with elements like vanadium and molybdenum to enhance strength while maintaining its lightweight nature. Common alloys include Ti-6Al-4V and Grade 2 commercially pure titanium.

Physical Characteristics

- Density: 4.506 g/cm³

- Melting Point: 1668°C

-

Thermal Conductivity: ~22 W/m·K

Mechanical Properties

- Tensile Strength: 900-1200 MPa for Ti-6Al-4V

- Excellent corrosion resistance due to its oxide layer

Industry Applications

- Aerospace: Airframe components

- Medical: Implants

Our machining services optimize designs for titanium’s properties.

The Essential Characteristics of Aluminum

Aluminum is a top choice for prototyping due to its lightness and versatility.

- Density: 2.7 g/cm³, about one-third that of steel

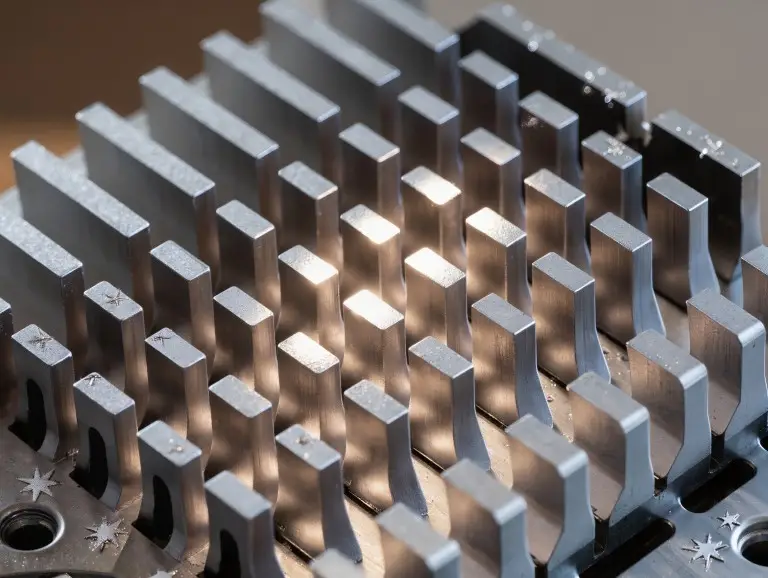

- Thermal and Electrical Conductivity: High, making it suitable for heat sinks and electrical applications

- Alloy Versatility: Can be customized with additives like magnesium or zinc

- Machinability: Easy to work with, reducing tool wear and processing time

- Corrosion Resistance: Self-forming oxide layer, though less durable than titanium in aggressive environments

We utilize aluminum for its ease of shaping into complex designs and its affordability for mass production.

Titanium Vs. Aluminum: A Direct Strength Comparison

When looking at a titanium vs aluminum strength comparison, we must consider key properties. Our team of material scientists helps choose the best material for projects. This is true for both prototyping and production.

Tensile Strength Differences

- Titanium alloys have a tensile strength of 900–1200 MPa, which is higher than aluminum’s 200–600 MPa.

- Aluminum’s lower strength means it’s not good for high-load jobs like turbine blades or aerospace fasteners.

Fatigue Resistance Considerations

Titanium holds up well under 10^7 stress cycles, which is key for parts like aircraft landing gear. Aluminum, on the other hand, can start to crack after a lot of stress.

Impact and Deformation Behavior

- Titanium bounces back to its original shape after an impact, keeping its dimensions.

- Aluminum, however, deforms by 20–30% under the same force, affecting the precision of moving parts.

Strength-to-Weight Ratio Analysis

Even though titanium is 60% denser (4.5 g/cm³ vs 2.7 g/cm³), its strength-to-weight ratio (~210-250 kN·m/kg) is better than aluminum’s (~150-210 kN·m/kg). This makes titanium great for lightweight yet strong applications like Formula 1 chassis or drone frames.

Our choice of materials balances cost and performance. For critical parts, titanium’s durability and strength are worth the extra cost. Aluminum is more affordable for non-critical prototypes.

Weight Considerations: How the Metals Compare

When we look at titanium and aluminum, density is key. Aluminum weighs about 40% less than titanium because it has a density of 2.7 g/cm³ compared to titanium’s 4.5 g/cm³. This means that parts made of aluminum can be up to 40% lighter for the same size.

But there’s more to it than just weight. Titanium and aluminum have different strengths and uses.

- Density Advantage: Aluminum is lighter, which is great for things like aircraft panels or car frames.

- Strength-to-Weight Balance: Titanium is stronger, so you can make things thinner without losing strength.

- Design Trade-Offs: Aluminum might be lighter upfront, but titanium can be just as light if designed right.

Our engineers use these differences to get the best results. In aerospace, we often pick aluminum for parts that don’t carry a lot of weight. But for engine mounts, we choose titanium for its strength.

In car design, we mix both. We use aluminum for the body and titanium for the suspension. We use CNC machining and investment castings to save material without losing function.

Every gram counts in important projects. We look at how thick things are, their shape, and how stress is spread out. This way, we save weight without losing strength. Whether it’s for an airplane part or a medical device, we find the right balance between titanium’s strength and aluminum’s lightness.

Cost Analysis: Budget Implications for Your Prototype

Choosing between titanium and aluminum means looking at costs. Our 15 years of making things show how important it is to think about money. We balance what you spend now with what you save later.

Raw Material Price Comparison

Aluminum costs about $2.8/kg, while titanium is $7-8/kg. This big difference shows that titanium is harder to get and make. For making lots of prototypes, aluminum is cheaper at first.

Processing and Machining Cost Factors

- Making titanium parts needs special tools, making them 3-10x more expensive than aluminum.

- It takes longer to cut titanium, adding 3-10x more time to make parts.

- Aluminum is easier to work with, saving time and money on tools and labor.

Long-term Economic Considerations

Aluminum is cheaper upfront, but titanium lasts longer. In harsh environments, titanium’s durability saves money over time. We help you decide based on your needs.

Also, using aluminum is better for the planet. It’s recyclable, saving on waste costs. We look at all these factors to fit your budget and needs.

Further Reading: Cost of CNC Prototyping

Machinability and Fabrication Challenges

Understanding the machining differences between titanium and aluminum is key to efficient production. Each material has its own challenges and advantages. Our team uses advanced techniques to create precise parts that meet your needs.

Titanium is strong and durable, but these traits make it harder to machine. Its low thermal conductivity causes heat to build up during cutting. This increases tool wear and requires slower cutting speeds—about 30–60% slower than aluminum. To handle these issues, we use methods like high-pressure coolant systems and carbide tools. These help reduce heat distortion and keep precision high. Titanium also hardens during cutting, so managing chips carefully is essential to avoid waste and work hardening.

Aluminum, in contrast, is much easier to machine. Its high thermal conductivity allows it to cool quickly, enabling faster CNC machining. This makes it perfect for quick prototypes and complex designs. Aluminum’s flexibility also makes it ideal for die casting and metal stamping. These processes cut down production time and costs for large orders.

- Tooling: Titanium needs ceramic-coated inserts and strong machine setups to handle vibration and wear. Aluminum, however, can be machined with standard HSS tools, which lowers production costs.

- Post-Processing: Aluminum’s lower melting point (660°C vs. titanium’s 1,660°C) makes welding and casting easier. Titanium, on the other hand, requires inert gas shielding to prevent oxidation during fabrication.

- Material Waste: Aluminum is more malleable, so it produces less scrap during machining. Titanium, being more brittle, tends to create more waste.

Our approach focuses on balancing the unique properties of titanium and aluminum with your project’s budget, timeline, and quality needs. Whether you’re working on aerospace components or medical devices, we offer custom solutions to tackle these material-specific challenges. This ensures the best results for your prototypes and production runs.

Corrosion Resistance and Environmental Factors

Choosing between titanium and aluminum for prototyping requires knowing about corrosion and environmental tolerance. Titanium and aluminum have different ways of handling harsh conditions. Our study shows that titanium lasts longer in extreme environments.

Titanium’s oxide layer (TiO₂) offers top-notch protection in marine, chemical, and industrial settings. Unlike aluminum, titanium doesn’t corrode quickly in saltwater. It keeps its protective film even in areas with lots of chloride.

Marine parts made from titanium resist corrosion that aluminum can’t handle. Our tests show titanium stays strong up to 600°C. This is higher than aluminum’s thermal limit.

Chemical Stability Comparison Titanium and aluminum have different chemical stabilities. Titanium stands up well against oxidizing acids and alkaline solutions. This makes it great for chemical processing equipment.

Aluminum, though it has a natural oxide layer, corrodes fast in extreme pH levels. Our lab tests show that titanium keeps 98% of its strength in sulfuric acid. Aluminum loses 30% of its strength under the same conditions. Aluminum also needs careful design to avoid galvanic corrosion when paired with other metals.

Surface Treatment Options Our engineers use advanced treatments to improve corrosion resistance:

- Aluminum: Anodizing thickens the oxide layer, boosting wear resistance and looks.

- Titanium: Custom anodizing adjusts oxide thickness for specific needs, ensuring consistent performance in corrosive environments.

Both metals get protective coatings—we use PTFE or ceramic on aluminum for extreme conditions. Titanium gets plasma spraying for offshore use.

For projects needing to last in harsh conditions, titanium’s corrosion resistance might be worth the extra cost. Our technical team looks at your project’s environmental needs to suggest the best material.

Thermal and Electrical Properties: Important Considerations for Specific Applications

When looking at titanium-aluminum properties contrast, how they handle heat and electricity is key. Aluminum is great for moving heat because it conducts it well, from 151–202 W/m·K. On the other hand, titanium doesn’t conduct heat as well (22 W/m·K), making it better for keeping things cool. These traits are crucial when designing prototypes.

- Aluminum melts at around 660°C, while titanium’s melting point exceeds 1,600°C.

- Electrical conductivity: Aluminum reaches 60% of copper’s conductivity, whereas titanium’s conductivity is only ~3% of copper’s.

- Thermal expansion: Aluminum expands more with temperature (2.32 x 10^-5/K) than titanium (8.6 x 10^-6/K), affecting part stability in fluctuating environments.

In aerospace or medical fields, titanium’s ability to handle heat is a big plus. For electronics, aluminum’s conductivity means less energy loss. Our CNC machining make the most of aluminum’s heat transfer abilities. Titanium, however, is perfect for high-voltage systems because it doesn’t conduct electricity.

Deciding between titanium or aluminum, which is better, depends on your project’s needs. Our team looks at thermal, electrical, mechanical, and cost factors to meet your goals. Reach out to us to see how these properties can solve your project’s challenges.

Industry-Specific Applications: When to Choose Which Metal

Choosing the right material depends on performance, cost, and how it works. This section shows when titanium or aluminum is best for different industries.

Aerospace and Aviation Requirements

Titanium is key in aerospace for parts like turbine blades and engine mounts. It can handle very high temperatures. Aluminum, on the other hand, is lighter, making planes up to 40% lighter.

Aluminum is cheaper for parts that don’t need to be as strong. But titanium is used for the most critical parts. We make aerospace-grade titanium parts with precision, down to 0.001mm.

Medical Device Considerations

In healthcare, titanium is the go-to material for implants because it’s safe for the body. It doesn’t corrode in body fluids and doesn’t react to MRI machines. Aluminum is not as safe for implants but is okay for external devices.

We follow strict ISO 13485 standards for making medical titanium implants.

Automotive Industry Applications

In cars, the focus is on saving weight and money. Aluminum is much lighter, which helps cars use less fuel. It’s also cheaper, making it great for body panels and engine blocks.

Titanium is stronger but more expensive. It’s used in high-performance exhaust systems. We make aluminum frames and titanium drivetrain parts with our CNC machining.

Consumer Electronics Applications

For gadgets, aluminum is better at cooling down parts like GPUs and batteries. It’s also good for parts that need to carry electricity. Titanium is too expensive for most gadgets, but it’s used in high-end casings.

We use laser cutting and bending to make aluminum chassis for gadgets. This helps make them lighter and cheaper.

Conclusion

Choosing between titanium and aluminum for prototyping is a complex decision. The right choice depends on your project’s specific needs. Both materials have unique benefits and downsides. This makes them good for different uses.

Titanium works well in tough, corrosive places. This includes aerospace, medical implants, and marine parts. It has great strength, corrosion resistance, and durability. However, it costs more and is harder to machine. This makes it a more premium choice. Aluminum is lighter and costs less. It is also easier to work with. This makes it a great fit when cost and weight matter most. Think of car parts, electronics, and fast prototypes.

For instance, titanium is often used for key parts in aerospace. This includes components like engine mounts. Aluminum is used for lighter parts with less stress, like panels. In the medical field, titanium is the top choice for implants. This is because the body accepts it well. Aluminum is better for devices used outside the body.

When picking materials for prototyping, you must balance performance, cost, and ease of making. This is where prototyping services become very important. They help you pick the best material early on. This avoids expensive changes later. It also ensures your project meets its technical and financial goals.

The right choice depends on what your project needs. It might require titanium’s strength and long life. Or it might need aluminum’s low cost and versatility. Yonglihao Machinery has over ten years of experience. We can help you make the best choice for your prototyping needs.

FAQ

What are the main differences between titanium and aluminum?

Titanium is stronger and more corrosion-resistant, suitable for high-stress environments. Aluminum is lighter and cheaper, ideal for applications where weight and cost are primary concerns.

Which material is stronger, titanium or aluminum?

Titanium has a higher tensile strength (900-1200 MPa) compared to aluminum (200-600 MPa).

What applications are best suited for titanium?

High-stress and corrosive environments, such as aerospace, medical implants, and marine applications.

Can aluminum be used in corrosive environments?

Aluminum has some corrosion resistance but may require additional protection in harsh conditions.

How do their thermal and electrical properties differ?

Aluminum has high thermal and electrical conductivity, while titanium has low conductivity in both aspects.

Why is material selection critical in the prototyping phase?

Selecting the right material early ensures that the project meets performance requirements and avoids costly redesigns later on.