Swiss machining has its origins in the Swiss watchmaking industry. Today, it is the key to manufacturing small precision parts with high accuracy. Precision is key in today’s manufacturing industry, especially in the aerospace and medical fields. Swiss machining is vital in these areas.

At Yonglihao Machinery, we have seen how precision manufacturing has changed the way production is done. We are a leader in metal machining, known for our technical competence and exceptional team. We provide high-quality solutions to a wide range of industries.

The Origins and Evolution of Swiss Machining

Swiss machining comes from Switzerland’s watchmaking tradition. It has grown into a complex manufacturing process. This growth is due to the need for precision and efficiency in making complex parts.

Historical Development in Switzerland

Swiss machining began in the late 19th century for watchmaking. It was made to create watch parts with fine details and high accuracy. Over time, it has acquired new technologies and methods.

Modern Advancements in Swiss Machining Technology

CNC (Computer Numerical Control) technology has changed Swiss machining. It’s now more efficient and precise. Modern Swiss CNC machines have 7 to 13 axes, making complex shapes and operations possible.

These machines use CNC technology for better repeatability and less setup time. They also have automatic tool changers and monitoring systems for consistent quality.

Swiss machining’s advancements have made it useful in many industries. It’s now a versatile solution for high-precision needs.

What is Swiss Machining?

Swiss machining is a precise and efficient manufacturing process. It started in Switzerland and is now a global standard for high-precision parts.

Definition and Basic Principles

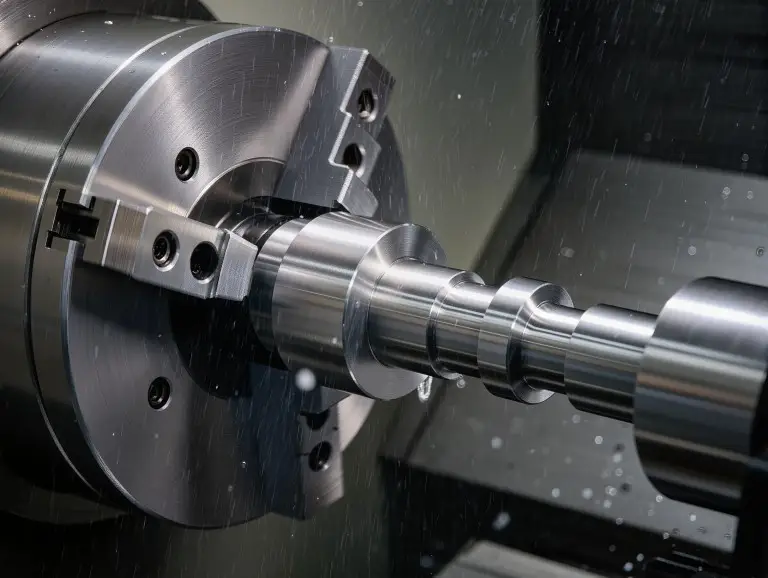

Swiss machining is known for its unique ability to move along the Z-axis. This allows for complex operations with high accuracy. In a CNC Swiss machine, the sliding headstock moves the metal stock through the guide bushing.

This setup ensures precise machining with minimal deflection. The guide bushing supports the workpiece right next to where the cutting happens.

Key Components of a Swiss Machine

A Swiss machine has key components like the guide bushing, sliding headstock, tool arrangement, and spindle system. The guide bushing is crucial for supporting the workpiece and reducing deflection.

- The sliding headstock mechanism controls the bar stock’s movement through the guide bushing during machining.

- The tool arrangement features multiple tool positions around the workpiece for simultaneous operations.

- The spindle system, including main and sub-spindles, allows for complete machining without manual help.

How Swiss Machining Works

Swiss machining works through the precise coordination of many components. It’s a complex process for making high-quality parts.

The Guide Bushing System

The guide bushing system is key in Swiss machining. It supports the workpiece near the machining area, ensuring minimal deflection and high precision. This system is vital for the accuracy of machining, especially for long and slender parts.

Sliding Headstock Mechanism

The sliding headstock mechanism is a key feature of Swiss machines. It holds and spins the material, allowing for precise control. This is essential for operations like turning, drilling, and milling.

Multi-Axis Operation

Modern Swiss machines have 7-13 axes of motion. This means they can perform many operations at once. These include turning, milling, drilling, threading, and grooving. This setup greatly reduces cycle times and boosts productivity for complex parts.

| Operation | Description | Benefit |

| Turning | Rotating the workpiece while a single-point tool moves along its length | High precision and surface finish |

| Milling | Using rotating multi-cutting tools to remove material | Ability to create complex geometries |

| Drilling | Creating holes using drill bits | High accuracy and repeatability |

Swiss machining’s precision and efficiency come from its guide bushing system, sliding headstock, and multi-axis operation. These components work together to make complex parts with high accuracy and less waste.

Swiss Machining vs. Conventional Machining Methods

Swiss machining is different from normal CNC turning. This is because of its special guide bushing system. It also has a sliding headstock. These parts offer better precision and control. This makes it great for certain jobs. Let’s see how Swiss machining compares to other methods. We will focus on turning and precision.

Swiss Turning vs. Traditional Turning

The main difference between Swiss and traditional turning is the guide bushing system. It also involves the sliding headstock part. These new ideas help Swiss machines give better precision. They also provide more stability. This is especially true for long, thin parts. These parts are hard for normal methods to handle.

Precision and Tolerance Capabilities

Swiss machining is known for its very tight tolerances. It can be as precise as ±0.0004mm on small, complex parts. This accuracy is very important for certain industries. These include medical devices, aerospace, and electronics. In these fields, even a tiny error can cause big problems. By contrast, conventional machining usually offers looser tolerances. It is often around ±0.01mm. This makes it a better fit for general factory work. It is also good for parts that do not need high precision.

| Machining Method | Tolerance Capability | Precision Level | Typical Applications |

| Swiss Machining | ±0.0004mm | High | Medical devices, Aerospace, Electronics |

| Conventional Machining | ±0.01mm (or looser) | Medium to Low | General manufacturing, Less precision-critical parts |

Benefits and Limitations of Swiss Machining

Knowing the benefits and limitations of Swiss machining is important for manufacturers. Swiss machining is known for its precision and efficiency in making complex parts.

Advantages in Precision Manufacturing

Swiss machining is great for precision manufacturing. It can maintain tight tolerances and create intricate geometries. The guide bushing system supports the workpiece well, ensuring high accuracy.

- High precision and accuracy

- Ability to produce complex geometries

- Ideal for small, intricate components

Limitations and Challenges

Swiss machining has its downsides. It can only work with bar stock sizes between 2mm and 38mm. This limits its use for bigger parts.

- Limited bar stock size (2 mm- 38 mm)

- Expensive specialized tooling

- Heat dissipation challenges due to oil lubrication

- Increased setup time due to complex tooling

Applications of Swiss Machined Parts

Swiss machined parts are used in many fields. This includes medical devices and aerospace components. Its precision and versatility make it perfect for various industries.

Medical Device Manufacturing

Swiss machining is key in making medical devices. It creates small, precise parts for surgical tools and implants. We do metal stamping and CNC machining for high-quality parts.

Aerospace Components

In aerospace, Swiss machining makes complex parts. These parts need high precision and quality. We use wire EDM and other methods to make these critical parts.

Electronics Industry

The electronics field benefits from Swiss machining. It makes small, detailed parts with high precision. This includes parts for electronic devices and connectors.

Automotive Applications

Swiss machining helps the auto industry. It makes precise parts for fuel systems, engines, and more. Our services include laser cutting and metal bending.

Watchmaking and Precision Instruments

Swiss machining started in watchmaking. It’s still crucial for making intricate mechanical parts. It’s also key for other precision instruments, like scientific devices.

Conclusion

Swiss machining has transformed precision manufacturing. It offers unmatched accuracy and efficiency for making small, detailed parts. At Yonglihao Machinery, we use our expertise in CNC machining services to provide high-quality, custom solutions. These solutions are designed to meet the specific needs of our clients.

Whether you need parts for medical devices, aerospace components, or precision instruments, our advanced capabilities deliver outstanding results.

By using the precision and flexibility of Swiss machining, we help industries achieve tighter tolerances and more complex designs. We also ensure consistent quality, even in large production runs. With a strong focus on technical excellence and innovation, Yonglihao Machinery is your reliable partner for precision manufacturing and turning services. Let us help you turn your ideas into reality with accuracy and dependability.

FAQ

What is the primary advantage of using Swiss machining for manufacturing small, complex parts?

Swiss machining is great for making small, detailed parts. It’s perfect for industries like medical devices, aerospace, and electronics.

How does the guide bushing system in Swiss machines contribute to precision?

The guide bushing system supports the cutting tool close to the workpiece. This reduces deflection and vibration. It improves precision and surface quality.

What materials are commonly used in Swiss machining?

Swiss machining works with many materials. This includes stainless steel, titanium, brass, and alloys. It meets the needs of different industries.

Can Swiss machining handle complex geometries and multiple operations?

Yes, Swiss machines can handle complex shapes. They can do multiple operations in one setup. This makes them versatile.

What are the typical tolerances achievable with Swiss machining?

Swiss machining can reach tolerances as tight as ±0.0001 inches. This depends on the machine and process used.

Is Swiss machining suitable for high-volume production?

Yes, Swiss machining is good for large production runs. It’s efficient, precise, and maintains quality over many parts.