Computer-aided design (CAD) is a powerful tool for metal processing. However, precision metal stamping still has its challenges. Factors like material thickness, hardness, and grain orientation can greatly affect the final product. Common materials include ferrous metals, non-ferrous metals, and stainless steel. Working with a metal stamping engineer early in the design process helps you choose the right material. This ensures the material meets your needs, avoids issues like cracking, and prevents costly mistakes for smoother production.

Design Criteria for Metal Stamping

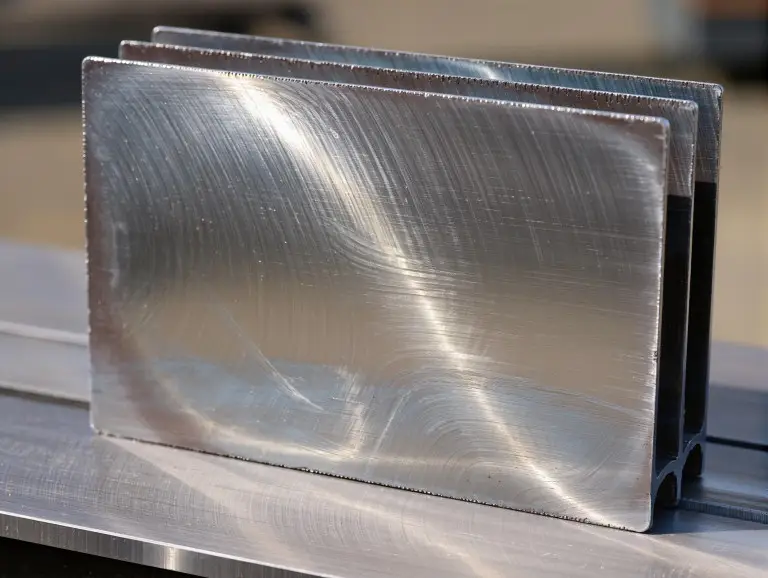

Metal stamping involves pressing and cutting metal sheets or coils into specific shapes. Techniques like punching, blanking, embossing, and progressive die stamping are used. These methods can work alone or together, depending on the complexity of the part. To get the best results, follow these key design guidelines.

Slots and Holes

Steel punches create holes and slots by pressing the metal into a die until it shears off. This process produces holes with a smooth top, a tapered bottom, and burrs. However, slots and holes are not perfectly straight. Secondary processing is needed for uniform walls, which increases costs.

Minimum Diameter: For ductile materials like aluminum, the hole’s minimum diameter should be at least 1.2 times the material thickness. For stronger materials like stainless steel alloys, use 2 times the thickness. Groove width should be at least 1.5 times the thickness. Smaller sizes require special tools, which raise costs and increase the risk of tool damage.

Distance from Edge: Place grooves and holes at least twice the material thickness from the edge. This prevents bulging or deformation, which would require rework and add costs.

Distance from Bends: For holes or slots less than 0.100 inches wide or thick, keep them at least twice the material thickness plus the bend radius from the bend. For larger ones, use 2.5 times the thickness plus the radius. Placing them too close risks distortion, swelling, or stretching.

Bending and Forming

Bends are often done in the final stages of progressive die stamping. Align the material grain perpendicular to the bend direction to avoid cracking. This is especially important for high-strength materials like stainless steel alloys or tempered metals. Always indicate grain direction on drawings.

Bend Height: Ensure there’s enough material by following a minimum height of 2.5 times the material thickness plus the bend radius. Shorter heights require extra manipulation, which increases costs.

Bending Near the Edge: Offset the material by at least the bend radius, or add a release cut. The groove should be at least twice the thickness wide and as long as the bend radius plus the thickness. This prevents tearing.

Preventing Deformation and Bulging: For thicker materials, add relief grooves on both sides of the bend to reduce bulging. Mark drawings to highlight areas where bulging is not allowed.

Dimensions and Tolerances

Measure punched or stamped features from the cut edge. Use the shortest cut for internal dimensions and the longest for external ones. For formed features, provide internal dimensions. Account for bend angle tolerances (±1 degree) and cumulative effects in parts with multiple bends.

Material Selection and Its Impact

Choosing the right material is critical for precision metal stamping. Material properties directly affect the process and the final product. Consult engineers to align your design goals with production realities.

Each metal type has unique traits that influence hardness, grain orientation, and thickness. Ferrous metals are magnetic but prone to rust. Non-ferrous metals resist corrosion. Stainless steel is strong and rust-resistant. Aluminum is lightweight and easy to form. Titanium and precious metals are strong and oxidation-resistant. Pre-plated metals and polyester films offer added protection, while wires are flexible.

Engineers can predict how materials will behave, suggest alternatives for brittle or crack-prone options, and prevent costly delays. This ensures quality and efficiency.

Support for Design for Manufacturing (DFM)

DFM integrates manufacturing considerations early in the design process. This makes products functional, appealing, and cost-effective while speeding up market entry.

Comprehensive DFM Review

A thorough review helps identify issues and opportunities:

- Check customer requirements for use, durability, and specifications.

- Ensure compliance with rules and standards.

- Evaluate materials for function and manufacturability.

- Confirm compatibility with existing tools.

- Address assembly and packaging needs.

Collaboration between manufacturers and stamping companies clarifies goals, provides production insights, and refines choices. This reduces the need for revisions.

The Role of Prototyping

Prototyping is essential for uncertain, complex, or innovative designs. It tests real-world performance and market response before mass production. Simulation software can model scenarios to identify weaknesses early. This reduces the need for physical prototypes and saves resources. Combining both methods offers the most thorough validation.

To Summarize

At Yonglihao, we understand that every detail in metal stamping design matters. By addressing the key aspects of the stamping process early in the design phase, you can streamline production, save time, reduce costs, and maximize efficiency. With our expertise and dedicated team, we turn your innovative ideas into practical, high-quality products.

From material selection to design optimization and every step of production, we are committed to delivering reliable and precise metal stamping services. Partnering with us means more than just great products—it means having a trusted partner to support you through every stage of your project.

FAQ

What materials are commonly used in metal stamping?

Common materials include stainless steel, aluminum, copper, and carbon steel. Each is chosen for its unique properties and applications.

How does material thickness affect the metal stamping process?

Thickness impacts tooling, die design, and the overall process. Thicker materials need stronger tools and higher press forces.

What are the key considerations for designing holes and slots in metal stamping?

Focus on size, shape, and location to ensure material compatibility. Follow minimum sizes and spacing to avoid distortion.

How can I prevent material distortion during the metal stamping process?

Choose the right materials, design carefully, and use proper tooling. Apply DFM principles and maintain adequate thickness.

What is the significance of the bend radius in metal stamping design?

The bend radius affects structural integrity and appearance. It prevents cracking and ensures a smooth finish.

How can I achieve cost savings in metal stamping design?

Optimize material use, simplify designs, and choose efficient processes. Use DFM principles to reduce production costs.