At Yonglihao Machinery, we focus on high-quality cnc services. We pay special attention to precision tapping. Tapping creates threaded holes for screws, bolts, and other fasteners. This step makes parts assemble securely. It provides reusable and reliable connections. In this article, we explore the importance of tapping. We look at how it has changed over time. We also explain how we use best practices. This helps us get high-precision results in every project.

What Is Tapping in Machining?

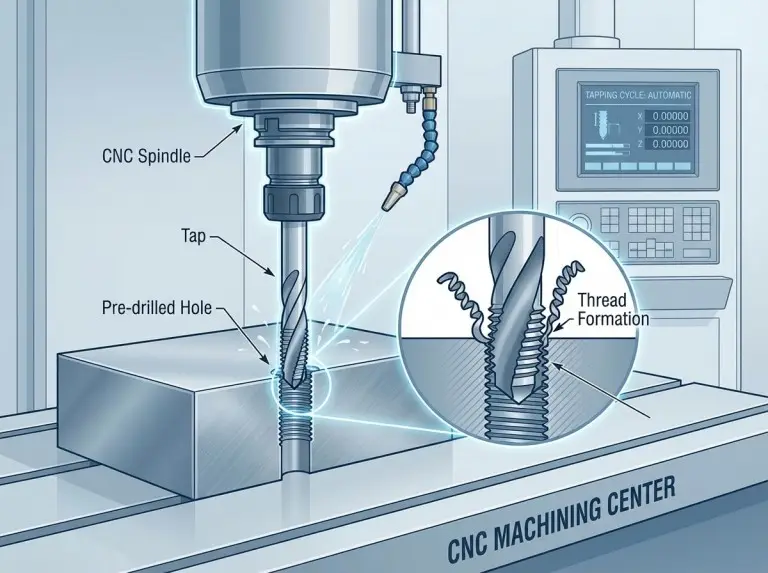

Tapping in machining creates internal threads in a pre-drilled hole. This lets fasteners like screws and bolts grip the workpiece firmly. Many industries need this process. These include automotive, aerospace, and electronics. They require precise and reliable threaded connections. Tapping uses a special tool called a tap. The tap cuts or forms threads inside the hole.

The main goal of tapping is to make the threaded connection resist shear forces. These forces happen when a fastener tightens. Precision in tapping matters a lot. Any misalignment or inconsistency can create weak threads. These threads may fail during use. At Yonglihao, we use advanced CNC machinery for tapping. This ensures high precision. All parts meet strict quality standards.

Main Types of Tapping

Choosing the right tapping method depends on the material. It also depends on thread specs and part complexity. Below are the main types of tapping methods we use at Yonglihao. Each fits specific applications.

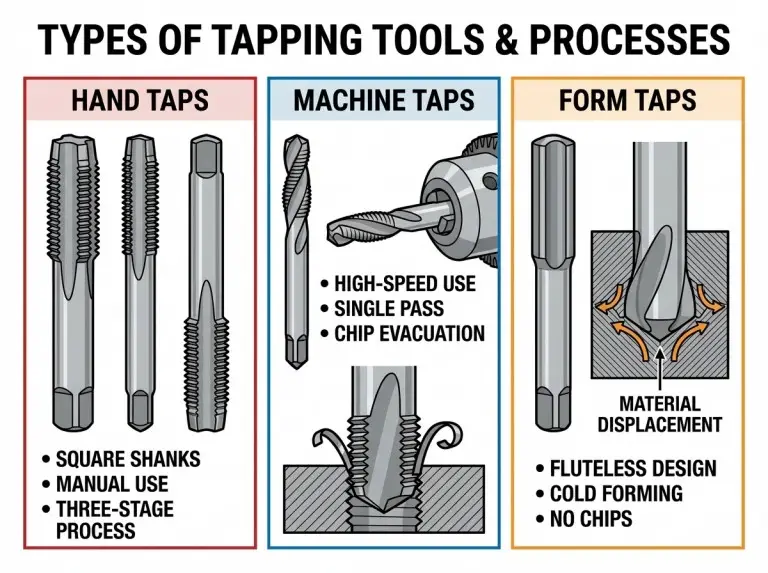

Hand Tapping – Manual Thread Creation

Hand tapping is a traditional method. Workers create threads manually with a tap and wrench. This technique fits smaller jobs or repairs. High precision is not always key here. It works well for soft materials like plastics and light metals. But it needs great skill. It can take a lot of time.

Machine Tapping – Automated Precision

Machine tapping uses automation for high speed and precision. We use CNC machines at Yonglihao for tapping. This allows faster production. It keeps tight tolerances. This method suits large-scale production. It also fits complex parts where consistency matters.

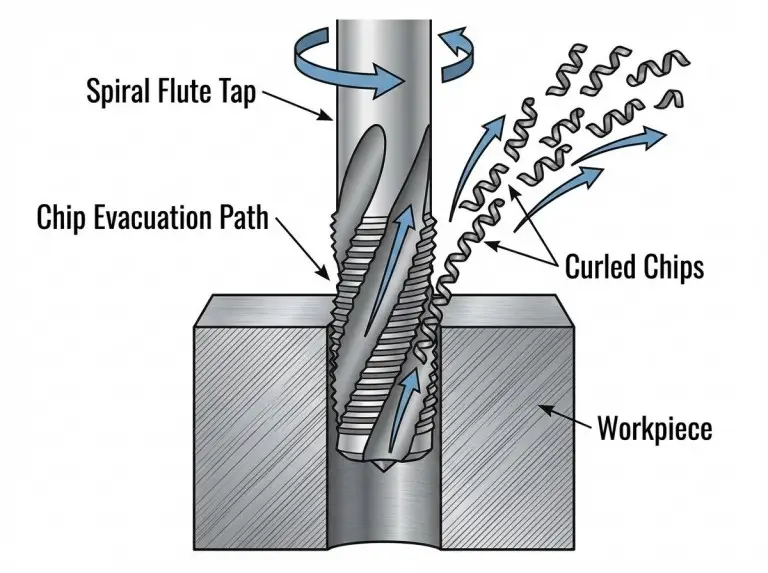

Cutting Tapping – Material Removal

Cutting tapping removes material to form threads. It works for many materials, including metals and plastics. This method allows threads of various sizes and shapes. It fits different machining needs. But it creates chips. Workers must remove these chips well. This avoids damage to the tap or workpiece.

Form Tapping – Thread Formation by Displacement

Form tapping creates threads by displacing material. It does not cut the material. This leads to stronger threads. The material’s structure compacts. It works well for ductile materials like aluminum and brass. At Yonglihao, we use form tapping where thread strength is key.

Rigid Tapping – High Precision Synchronization

Rigid tapping syncs the tap with the machine’s spindle. This ensures perfect alignment between the tap and hole. It reduces misalignment. It improves thread accuracy. This method helps in jobs that need tight tolerances. It also creates high-quality threads.

Floating Tapping – Misalignment Compensation

Floating tapping allows small misalignments between tap and hole. It uses a floating tap holder. This holder fixes deviations. The method fits cases where perfect alignment is hard. It lowers the risk of tool breakage. It also reduces thread damage.

Synchronous Tapping – Automated Reversal

Synchronous tapping reverses the tap automatically after threading. This reduces manual work. It boosts efficiency. It fits high-volume production. At Yonglihao, we use it for jobs needing high precision. It also causes minimal tool wear.

How to Choose the Right Tapping Process

Selecting the right tapping process is key for thread quality. It also affects tool life and production speed. The choice depends on material, thread size, and project complexity. Cutting tapping works for many materials. Form tapping suits ductile materials that need strong threads. Rigid tapping fits high-precision jobs. Floating tapping helps when alignment needs flexibility.

At Yonglihao, we review each project. We pick the most efficient and cost-effective method. Our skills ensure the process gives the best results. It meets your specific needs.

Best Practices for Efficient Tapping

To get the best results in tapping, we follow key practices. These improve thread quality, tool life, and work efficiency. The practices include:

- Proper Lubrication: Good lubrication cuts friction. It prevents heat buildup during tapping. At Yonglihao, we use high-quality cutting oils. These extend tool life. They improve thread finish.

- Optimizing Speed and Feed Rates: We set correct speed and feed rates. These base on material and tap type. This avoids tool wear. It ensures consistent thread quality.

- Tool Life Management: We track tool performance. We replace tools on time. This prevents downtime. It ensures high-quality threads.

- Chip Evacuation: Good chip removal prevents tap breakage. It keeps thread integrity. We use advanced tap holders and coolant systems. These remove chips from the hole well.

By following these practices, we make our tapping operations efficient. We produce high-quality, reliable threads.

Common Challenges in Tapping and How to Overcome Them

Tapping can bring challenges like tap breakage, thread damage, and poor chip removal. At Yonglihao, we have ways to fix these:

- Tap Breakage: To stop breakage, we use the right tap size for each job. We ensure proper alignment. We watch cutting speeds and feed rates closely.

- Thread Damage: Thread damage happens if the tap misaligns or material is too hard. We fix this with the right tap type. We keep strict control over machine settings.

- Chip Accumulation: Chips can clog the hole. This damages the tap and workpiece. We use peck tapping cycles. We also use special tools to improve chip removal and stop clogging.

By handling these challenges early, we keep our tapping processes smooth. We make them efficient. This cuts production disruptions.

Conclusion

Tapping is a key operation in CNC machining. It creates strong, precise threaded connections in various materials. At Yonglihao, we use advanced tapping technologies. We follow best practices. This ensures every threaded part meets high standards of quality and precision. You may need simple threaded holes in aluminum. Or you may need complex threading in exotic alloys. Our skills in tapping give the best results for every project.

FAQ

What is the difference between hand tapping and machine tapping?

Hand tapping is a manual process. It needs skill and precision. Machine tapping is automated. It offers greater speed and consistency. Machine tapping fits large-scale production.

Why is lubrication important in the tapping process?

Lubrication cuts friction between tap and workpiece. It prevents tool wear. It improves thread quality. It also cools the tap. It ensures smooth chip removal.

How can I prevent tap breakage during tapping?

To prevent tap breakage, ensure proper alignment. Use the correct tap size. Maintain optimal cutting conditions. Check the tap for wear often. Replace it if needed.

What challenges are associated with blind hole tapping?

Blind hole tapping brings issues like chip buildup and depth control. We use special techniques like peck tapping. We also use bottoming taps. These fix the issues and ensure accurate threads.

How do you ensure thread accuracy in tapping?

We use thread gauges and coordinate measuring machines (CMM). These check thread dimensions. We keep strict control over cutting conditions. This ensures all threads meet required specs.