Die Casting Services

Yonglihao Machinery offers customized die casting services that ensure high precision and tailor solutions for your specific needs. We can make complex metal parts with great accuracy. They meet the needs of industries like automotive, aerospace, electronics, and medical devices. All parts are ISO 9001:2015, ISO 13485, ISO 14001:2015, and IATF 16949:2016 certified, with fast turnaround times and a commitment to quality.

- Achieve tight tolerances for various applications

- Perfect for intricate and detailed parts.

- Machining aluminum, zinc, Tooling Steels.

- Certifications: ISO 9001:2015, ISO 13485, ISO 14001:2015, IATF 16949:2016

Home » Die Casting Services

What is Die Casting?

Die casting is a manufacturing process. In it, molten metal is injected into a mold at high pressure. This creates complex and precise metal parts. This method is efficient and low-cost. It makes many high-quality parts. Yonglihao Machinery offers two main types of die casting: hot chamber and cold chamber.

Die Casting Capability

Below are design and quoting guidelines commonly used in die casting projects. Final capability is confirmed after DFM + tool design review (part geometry, alloy, gating, and machining strategy).

| Item | Practical guideline (reference) |

|---|---|

| Dimensional tolerance | As-cast: depends on size/geometry; Critical features typically require machining |

| Machined accuracy | On qualified geometries, ±0.01 mm can be achievable after DFM review |

| Minimum wall thickness | Aluminum: ~1.5 mm typical; Zinc: down to ~0.8 mm typical (part-dependent) |

| Wall thickness ratio | Keep transitions within ~1:3 to improve filling and reduce shrink risk |

| Small holes / threads | Very small holes often need drilling; threads are usually machined for reliability |

| Draft angle | Start at ≥0.5° (more draft improves ejection and surface quality) |

| Lead time | Tooling + samples commonly 3–6 weeks depending on complexity |

| Volume / MOQ | Low-volume options are possible; production economics usually improve at hundreds+ of pieces |

Die Casting Materials

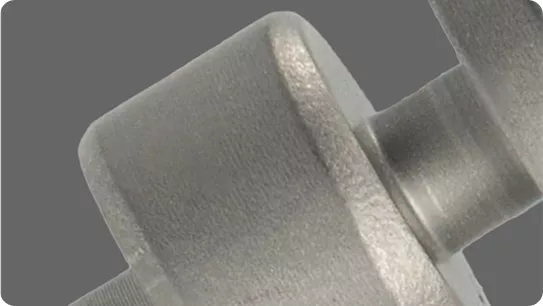

In die casting, tooling steel determines die life, thermal cracking risk, and surface consistency. Meanwhile, the casting alloy affects weight, strength, corrosion resistance, machinability, and overall cost. Below is a breakdown of materials we commonly evaluate during quoting and DFM (final selection depends on part geometry, duty cycle, and quality targets).

H13: H13 is a popular choice for pressure die casting. It maintains strength at high temperatures and offers reliable toughness. This makes it ideal for aluminum and magnesium tooling, especially under repeated thermal loading and high injection pressure.

8407 : This steel is preferred when thermal shock and heavy-duty cycling are key concerns. It provides higher toughness and better heat transfer, which helps reduce localized overheating and extends die stability in demanding production runs.

2344: 2344 is used when a balance of hot strength and thermal fatigue resistance is needed. It’s also machining- and polish-friendly, making it a practical option for dies requiring fine details, stable surface quality, or high cosmetic standards.

Note: Steel choice is just one factor. Heat treatment, cooling layout, gating/venting design, alloy temperature range, and maintenance practices also play critical roles in die life.

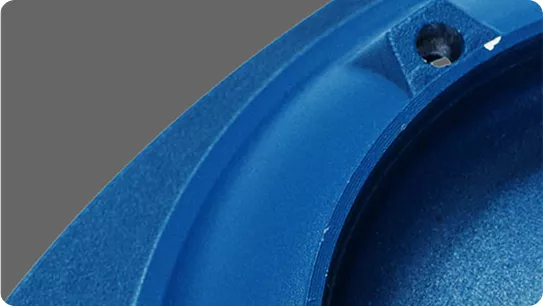

Aluminum die casting is ideal for lightweight parts with good corrosion resistance and a strong strength-to-weight ratio. It’s commonly used in automotive housings, brackets, electronics enclosures, heat sinks, and other thin-walled structural components where repeatability is essential.

Supported alloys (project-specific) include:

- ADC10

- A380

- ADC12

- Pure Aluminum (for specific needs)

- DM6 / HA6 / HA4 (depending on application and supply)

Selection guidance: Consider wall thickness, rib density, sealing needs, and downstream finishing (including appearance sensitivity) during DFM.

Zinc alloys are known for excellent mold flow and strong dimensional accuracy, making them ideal for small parts with fine features and tight tolerances. They are often used in connectors, locks, hardware, and compact electronic components where cost and consistency are priorities.

Common zinc grades include:

- ZAMAK 2

- ZAMAK 3

- ZAMAK 5

Selection guidance: Mechanical load, corrosion environment, plating/coating needs, and insert/thread strategies influence the best ZAMAK choice.

Surface Finishes

Die-cast parts—especially aluminum and zinc—often come out of the tool with a clean surface. However, when a project requires better appearance, corrosion protection, paint readiness, or wear resistance, we can apply finishing and secondary operations. These are tailored to your drawing and the part’s end-use environment. If you have specific cosmetic standards or test requirements, we’ll align the finish plan during DFM.

If your part includes tight-tolerance datums, sealing faces, small holes, or threads, we typically recommend secondary CNC machining for those critical features, then apply the final finish afterward to protect the functional surfaces.

Advantages of Custom Die Casting

High Precision and Accuracy: Custom die casting makes parts with tight tolerances. It also makes parts with complex designs. This ensures high precision and consistency. This is critical for parts that require precise dimensions and complex geometries.

Efficiency: Known for its high productivity, die casting is an efficient process for producing large quantities of parts quickly. This method also minimizes waste as excess material can be reused, making it more cost-effective.

Durability: Parts produced through die casting are robust and dimensionally stable. The process creates strong parts. The parts can handle many types of conditions and stresses.

Versatility: Custom die casting is used in many industries. These include automotive, aerospace, electronics, and medical devices. It also supports many materials and alloys. This allows for choosing the best solution for specific needs and performance.

Yonglihao Machinery’s custom die casting provides the best solution for producing high-quality, durable, and precise parts that meet specific industry needs.

Applications of Die Casting

Yonglihao Machinery produces custom die castings. They are for a wide range of applications in many industries. The castings meet the need for high precision and durability in different sectors. No matter how complex your project needs are, we can provide you with the most suitable products and services. Here are some of the main application areas we currently work with:

Why Choose Yonglihao Machinery?

Experience & Engineering

DFM-first engineering reduces porosity risk and rework. We translate drawings into stable tooling and repeatable production.

Certified Quality System

We operate with certified management systems: ISO 9001, ISO 13485, ISO 14001, IATF 16949, and AS9100. Certificates and scope statements are available for verification.

Materials & Process Coverage

We focus on tooling steels, aluminum, and zinc for dependable die casting output. Machining and finishing complete the part to print-ready condition.

FAQ

Hot chamber casting is faster. We use it mostly for zinc. It works for some magnesium too. We use cold chamber casting for aluminum. It also suits alloys that need high temperatures.

We can often meet this on specific shapes. However, it usually needs extra CNC machining. You also need a clear plan for inspection.

For aluminum, the standard thickness is 1.5 mm. Zinc parts can be as thin as 0.8 mm. This depends on the shape of the part. It also depends on the flow.

We usually drill small holes. This is common for holes under 3 mm in aluminum. We machine threads separately. This ensures they fit well. It also keeps them consistent.

The minimum order is usually 500 to 1,000 pieces. The lead time is often 20 to 25 days. This depends on the type of mold. It also depends on how complex the part is.

Zinc tools can last up to 1,000,000 cycles. Magnesium and aluminum tools usually last about 100,000 cycles. The actual life varies. It depends on the alloy and tool design. Cooling and maintenance also affect the life of the die.