Brushing Services

Yonglihao Machinery offers brushing services to create a controlled, directional grain on part surfaces. This process enhances appearance, minimizes random tool-mark reflections, and provides a consistent texture for cosmetic panels and visible components.

- Consistent directional brushed texture

- Customizable grain direction to match design intent

- Stable surface preparation for anodizing, painting, or powder coating

Home » Surface Finishing Service » Brushing Services

What Is Brushing?

Brushing is a mechanical surface finishing process that uses abrasive brushes, belts, or wheels to create a uniform, linear grain. It enhances cosmetic appearance and produces a repeatable surface texture, ranging from light satin to a more pronounced brushed finish.

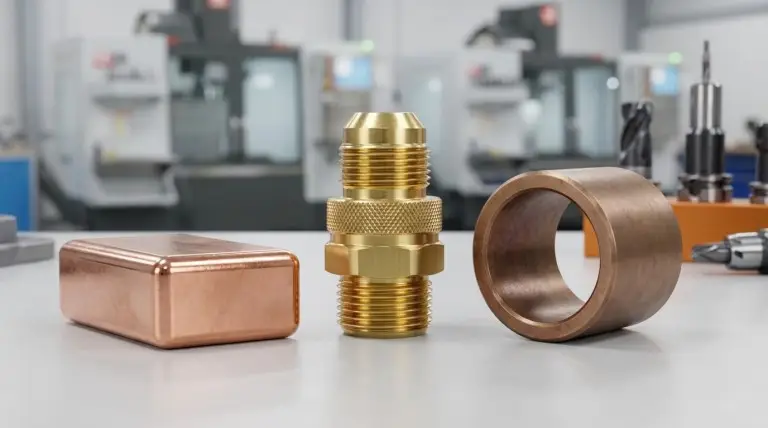

This process is most commonly applied to metals like stainless steel and aluminum. It can also be used on carbon steel, brass/copper alloys, and some plastics, depending on their hardness and cosmetic requirements (subject to review).

However, brushing follows the base surface. Deep scratches, dents, pits, and casting defects will remain visible. The final appearance depends on the material, its initial condition, the tools used, and the brushing direction.

One-Stop Manufacturing

We can apply brushing as a downstream step for parts made through:

Surface Preparation & Final Appearance

Brushing creates a linear grain but does not produce a mirror polish. It reduces the visibility of light marks and gives front-facing surfaces a more premium look.

| Surface prep | Applicable materials | Texture | Visual appearance | Notes |

|---|---|---|---|---|

| As-machined / cleaned | Stainless steel, aluminum (review), carbon steel (review), some plastics (review) | Satin to brushed grain | Directional lines, uniform reflection | Deep defects remain visible; grain direction must be specified |

FAQ

What does a brushed finish look like?

It features a uniform linear grain with a satin reflection. The grain’s strength depends on the abrasive used.

Can brushing hide scratches?

It reduces light marks but does not remove deep scratches, pits, or dents.

Will brushing change dimensions?

Material removal is minimal, but tight-tolerance features should be masked or excluded.

Can you brush only one face?

Yes. Mark the cosmetic faces and grain direction on the drawing.

Is brushing compatible with anodizing or coating?

Yes. Brushing is often used to create a consistent texture before anodizing or painting.

What materials can be brushed?

Stainless steel and aluminum are most common. Other materials are reviewed based on hardness and cosmetic goals.