Choosing the right CNC tool holder is crucial. Your choice affects grip security, runout risk, and tool-change speed in CNC milling. At Yonglihao Machinery, we often see tool holders cause unnecessary scrap when they are treated like accessories instead of a vital link between the spindle and the cutter. This article explains the main tool holder types, their typical uses, and what to check before finalizing a setup.

A “better” holder isn’t a one-size-fits-all upgrade. The right choice depends on your spindle interface, cutting load direction, required surface finish, and access needs. It also depends on how your shop handles tool setup. The goal is to help you pick a holder that matches the job and verify the assembly for repeatable results.

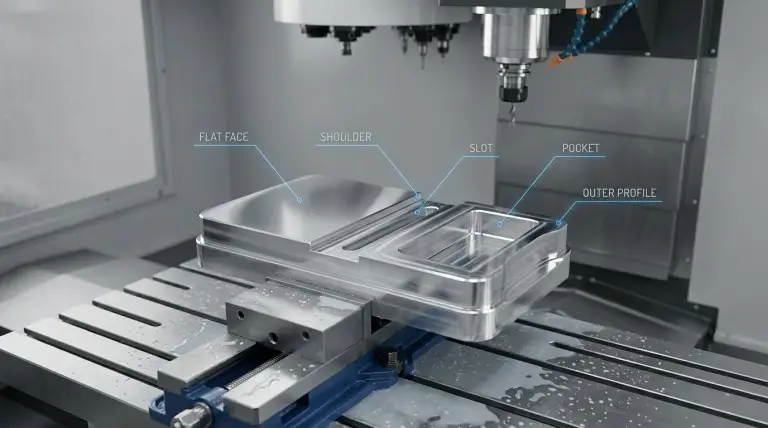

Tool Holder Anatomy and Key Terms

A tool holder’s anatomy determines how well you can control machining risks like retention, torque transfer, and tool stickout. It’s not just the part that clamps the tool; it’s a system including the spindle connection, retention mechanism, and clamping mechanism.

The spindle-side interface is the first constraint. The shank and taper must match the machine’s spindle. When using an automatic tool changer, the flange geometry must also be compatible. If the interface is wrong, no “better” chuck can fix the problem safely.

Retention hardware is a common point of failure. Many steep-taper systems use a retention knob or pull stud to let the drawbar hold the tool holder. If this hardware is incorrect, worn, or mismatched, you might see runout, fretting marks, or tool pullout during a cut.

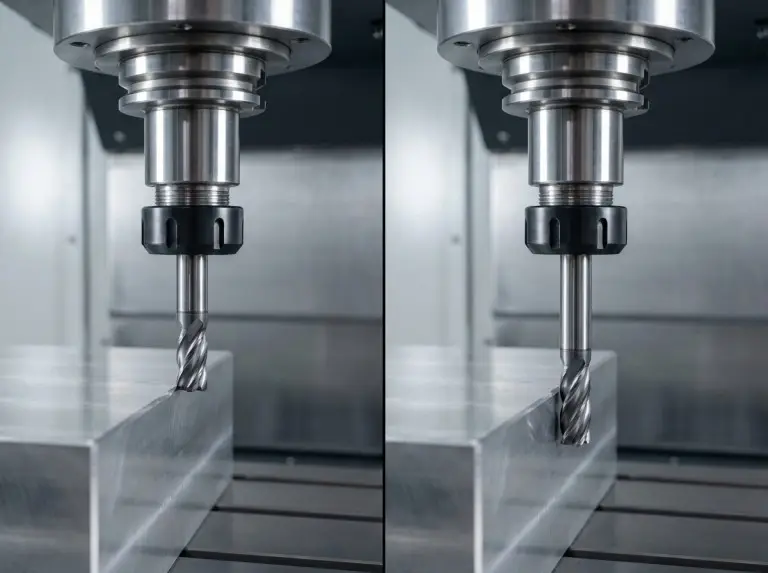

The clamping mechanism defines how the holder grips the tool and reacts to axial force. A collet is a split sleeve that collapses onto the shank. A chuck-style mechanism uses a different internal structure. The clamping method determines what you need to check, such as torque, sleeve condition, and cleanliness.

Gage length and stickout are important variables. A longer stickout increases leverage, which can amplify vibration and deflection, even with a high-quality holder. If a job requires deep reach, choose a holder designed for both access and stability, and then verify it with the actual tool assembly.

Common Misconceptions About Tool Holders

Most tool holder problems come from a mismatch between the holder type, assembly method, and cutting load, not from “tool holder quality” alone. Teams often switch holders but keep the same assembly habits, stickout, and cutting parameters. This approach rarely fixes the root cause.

Runout numbers alone don’t determine the best holder. Runout is affected by the spindle’s condition, taper cleanliness, collet condition, assembly torque, and tool shank quality. A holder with a great runout spec can still cut poorly if the rest of the system isn’t managed.

Grip strength isn’t the only thing that matters. Some jobs need maximum pullout resistance, while others need stable concentricity and damping to prevent chatter. Assuming “more grip is better” for every job can lead to imbalance, limited access, or slower tool changes.

Quick-change systems don’t guarantee better accuracy. Faster changeovers are helpful only if your workflow includes presetting, repeatability checks, and verification. If offsets drift and assemblies are inconsistent, speed gains can turn into rework.

Main CNC Tool Holder Types

Modern CNC milling uses a few key tool holder types. Each offers a trade-off between grip strength, runout control, damping, access, and speed. The sections below describe where each type fits best and what to verify.

Collet Chucks: General Milling Flexibility

Collet chucks are ideal for frequent tool size changes and general-purpose use. Shops use them for drilling, light-to-moderate milling, and managing diverse tool inventories. Swapping collets is often faster than rebuilding entire assemblies. They are also useful when you need a compact nose profile without needing the absolute slimmest option.

Using collet chucks requires discipline. You must monitor collet condition and use consistent assembly torque. Collets and nuts wear out, and debris in the taper or threads can cause inconsistent clamping. A collet chuck is a safe default only when pullout risk is low and the shop keeps collets clean and replaced on schedule.

Side-Lock Holders: Heavy Cut Pullout Resistance

Side-lock end mill holders are the best choice when tool pullout is the main concern in roughing cuts. A set screw engages a flat on the tool shank, preventing the cutter from slipping out under heavy axial loads. This is useful for aggressive slotting and other operations that tend to pull on the tool.

Side-lock holders trade some concentricity for mechanical security. The set screw can push the tool slightly off-center. This makes them less than ideal for finishing passes where surface quality is sensitive to vibration. Many shops rough with side-lock holders and then switch to a different type for finishing.

Milling Chucks: High Grip Without a Flat

Milling chucks offer high gripping power for demanding milling without needing a set-screw flat. They are often chosen for more pullout resistance than a standard collet chuck can provide. This makes them a popular choice for roughing and other heavy-engagement strategies.

Milling chucks still need to be checked for balance, stickout, and assembly condition. If the job involves high spindle speeds or tight finish requirements, the entire assembly should be treated as a balanced system. Tool reach and nose geometry are also important, as milling chucks can be bulkier than slimmer alternatives.

Hydraulic Chucks: Damping and Finish Stability

Hydraulic chucks excel at controlling vibration and ensuring surface finish stability. The hydraulic mechanism clamps the shank with uniform pressure. Teams often use them for finishing, reaming, and operations where chatter is a problem. They also allow for predictable tool changes without needing heating equipment.

Hydraulic systems require careful handling. Over-tightening, running without a tool, or damaging the internal clamping area can degrade performance. A hydraulic chuck should be treated as a precision component with a clear maintenance and inspection schedule.

Shrink Fit Holders: Slim Access and Concentricity

Shrink fit holders are perfect when you need a slim profile and stable concentricity for deep features. The thermal process creates a powerful interference fit. This is great for finishing and multi-axis work where clearance is tight. Many also choose shrink fit for high-speed stability when managed correctly.

Shrink fit requires special equipment and controlled processes. Tool changes rely on heating and cooling units, and you must keep the bore clean. Shrink fit also demands exact shank sizes, so inventory planning is part of the decision.

Press-Fit Systems: High Grip, Repeatable Swaps

Press-fit toolholding systems provide a strong grip and controlled runout while allowing repeatable tool changes with a press. This approach is often seen as a middle ground between general collets and shrink fit systems. It suits production environments that want mechanical repeatability without heat.

The reliability of press-fit systems depends on sleeve condition and a consistent press process. Sleeves and interfaces wear down. The assembly sequence must be consistent to prevent drift. They work best in shops that already have a structured presetting and verification process.

Shell Mill Arbors: For Large Diameter Cutters

Shell mill arbors are made for face mills and other cutters designed to mount on a pilot with drive keys. The pilot centers the cutter, and the keys transmit torque, which is essential for high-volume face milling. This is not a substitute for a shank-held end mill and should only be used with arbor-mounted cutters.

Arbors require you to verify key engagement and proper seating. Debris between the cutter and arbor face can cause wobble and a poor finish. The retention screw’s condition and seating torque must be controlled to prevent it from loosening.

Tapping Holders: For Thread Quality and Tap Life

Tapping holders are used when protecting taps and ensuring thread quality are the main goals. Rigid tap holders work well if the machine reliably controls tapping synchronization. Tension-compression holders can help when uncertain synchronization or other setup issues risk breaking taps.

The holder choice should match the real tapping environment, not an ideal one. If thread depth, pitch, or material creates high torque sensitivity, the holder should be chosen with a plan to verify alignment and axial compliance. A tap holder is primarily a risk-control device.

Drill Chucks: For Light-Duty Drilling Convenience

Drill chucks are best for light-duty drilling where convenience is more important than strict concentricity. They can be useful for mixed drilling tasks, especially when you need to change between many drill sizes quickly. In most CNC milling shops, they are a secondary option, not a primary production holder.

Drill chucks should be seen as limited-scope holders. If the job is sensitive to runout, hole location, or finish, a collet-based or other precision holder is usually a safer choice. The decision should be based on the risk to the part, not on habit.

Modular Tooling: For Fast Offline Presetting

Modular tooling systems are most effective when the goal is to reduce machine downtime through offline presetting and quick swaps. These systems separate a base coupling from the cutting head. This allows for repeatable head changes with less setup time. They are most valuable when a shop has a defined presetting process and needs stable repeatability.

Modular systems require process maturity to be effective. If tool data management, presetting, and verification are weak, faster swaps can just move problems into production. The decision to use them should be tied to a specific downtime issue and a clear repeatability need.

How to Choose Between CNC Tool Holder Types?

The safest way to select a tool holder is to start with the spindle interface, pullout risk, access length, and surface finish needs. Then, verify the assembled system on the machine. Many errors happen when teams pick a holder by its name without defining the risk it needs to control. The factors below help turn a list of “types” into a decision process.

- Spindle Interface: This is the first gate. Common interfaces include steep-taper and hollow-shank styles. Each changes how the holder seats and performs. If the spindle interface is fixed, your choice is limited to holders that fit that interface, the tool changer, and the retention system.

- Pullout Risk: Assess this based on the operation, not just the material. Slotting and heavy axial cuts can create forces that make general collets risky. If pullout is the main risk, side-lock, milling chucks, shrink fit, or press-fit systems are better choices. Always verify on the actual setup.

- Surface Finish: Finish or chatter sensitivity points toward holders with good damping and concentricity. If the finish is critical, hydraulic chucks and shrink fit are common choices. You should validate the stability at the actual stickout. If throughput is more important than finish, a high-grip holder might be better.

- Access and Gage Length: These factors determine if a “better” holder is even usable. A bulky holder might not reach certain features, forcing a longer stickout and creating less stability. Choose the holder, cutter length, and part geometry together.

- Tool Change Workflow: Your presetting discipline determines if modular systems are worth it. If you already use offline presetting and need frequent swaps, modular tooling can reduce downtime. If not, improving your assembly verification might be more valuable.

The table below summarizes how holder types map to goals and what to check first.

|

Tool holder type |

Typical CNC milling use |

First thing to verify |

|---|---|---|

|

Collet chuck |

General milling and drilling |

Collet/nut condition and torque |

|

Side-lock end mill holder |

Roughing with high pullout risk |

Tool flat engagement and runout |

|

Milling chuck |

Heavy milling with high grip |

Assembly balance and clearance |

|

Hydraulic chuck |

Finishing and sensitive operations |

Clamping integrity and seating |

|

Shrink fit |

Slim access and concentricity |

Bore cleanliness and heat process |

|

Press-fit system |

High grip with repeatable changes |

Sleeve wear and press consistency |

|

Shell mill arbor |

Face milling with arbor cutters |

Seating cleanliness and key fit |

|

Tapping holder |

Threading with tap protection |

Alignment and compliance level |

|

Modular system |

High mix with offline presetting |

Coupling repeatability and presetting |

Verification Checklist for Setup and Maintenance

Tool holder performance is repeatable only when the shop verifies cleanliness, clamping, alignment, and wear for every tool. This is not “extra work” when you consider the cost of scrap and rework. The checklist below can be executed quickly.

Start with taper and interface cleanliness at every tool change. Chips or residue on the tapers can cause runout, fretting, and instability. A simple wipe often solves many “mystery vibration” issues.

Control clamping torque and assembly sequence as a defined process. Collet and chuck systems are sensitive to how they are tightened. Inconsistency can lead to drifting tool length or variable grip. Standardize torque tools or, at the very least, the tightening method.

Verify tool stickout and clearance on the actual part. A holder that looks fine in a catalog might hit clamps or other features. If you must use a longer stickout, treat it as a design change and choose the holder accordingly.

Inspect for wear on a schedule based on usage, not the calendar. Look for fretting marks on tapers, damaged collet seats, cracked nuts, and scarred bores. If a holder behaves inconsistently, remove it from production for inspection.

The table below links each action to the failure it prevents.

|

Verification action |

What it prevents |

What “pass” looks like |

|---|---|---|

|

Clean tapers before insertion |

Runout spikes and fretting |

Clean surfaces, no debris |

|

Check retention hardware |

Loss of retention, bad seating |

Correct hardware, no damage |

|

Standardize tightening |

Inconsistent grip, offset drift |

Repeatable routine, consistent tools |

|

Confirm stickout and clearance |

Chatter, deflection, collisions |

Minimum stickout, verified clearance |

|

Inspect and replace worn parts |

Gradual loss of accuracy |

Clamping elements are undamaged |

|

Store holders in protected racks |

Nicks and dents |

Contact surfaces are protected |

Conclusion

At Yonglihao Machinery, we see CNC tool holder selection as a system for reducing scrap. The choice should be tied to verifiable risks. Select your holder based on the spindle interface, pullout risk, finish sensitivity, and access needs. Then, validate it with a consistent assembly and inspection routine. When these steps are in place, teams spend less time fighting chatter and more time cutting good parts.

If you are planning work through our CNC machining services, including 5 axis milling services, share your spindle interface, operation type, stickout constraints, and critical features. We can help you map those needs to a holder type and a verification plan that fits your workflow.

FAQ

What is the best CNC tool holder for milling?

The best holder depends on the operation’s pullout risk, finish needs, and access constraints. Collet chucks are great for general tasks, but heavy roughing often requires higher-grip options. The safest approach is to choose based on the dominant risk and verify the assembly.

When should I avoid a side-lock holder?

Avoid a side-lock holder when finish quality, vibration sensitivity, or concentricity is the main goal. The set screw can cause runout, which is fine for roughing but not for finishing. Many teams rough with side-lock and finish with a different holder.

Why do two collet chucks act differently?

Two setups can differ due to collet wear, nut condition, assembly torque, cleanliness, or shank differences. Collet systems are sensitive to small changes. Standardizing assembly and replacing worn parts usually improves repeatability.

Is a hydraulic chuck always better for finish?

A hydraulic chuck often helps when damping is the limiting factor, but it’s not a universal solution. If pullout risk is high, a higher-grip system may be safer. The right answer depends on the operation and should be verified on the part.

Do modular systems always reduce cycle time?

Modular systems reduce downtime only if the shop uses offline presetting and repeatable procedures. If offsets drift or assemblies vary, faster swaps can cause more troubleshooting. They work best when processes are already under control.

What’s the fastest way to improve reliability?

The fastest way is a verification routine for cleanliness, consistent assembly, and wear inspection. Many “tool holder problems” are from dirty tapers, inconsistent tightening, or worn parts. A simple checklist often stabilizes results without new hardware.