Choosing the right CNC milling machine depends on part geometry, setup strategy, and production goals. Many teams compare “vertical vs. horizontal vs. 5-axis” but overlook key factors like chip evacuation, fixture access, and multi-face machining. This article organizes CNC milling machine types with clear labels and provides verification questions to guide your purchasing and quoting process.

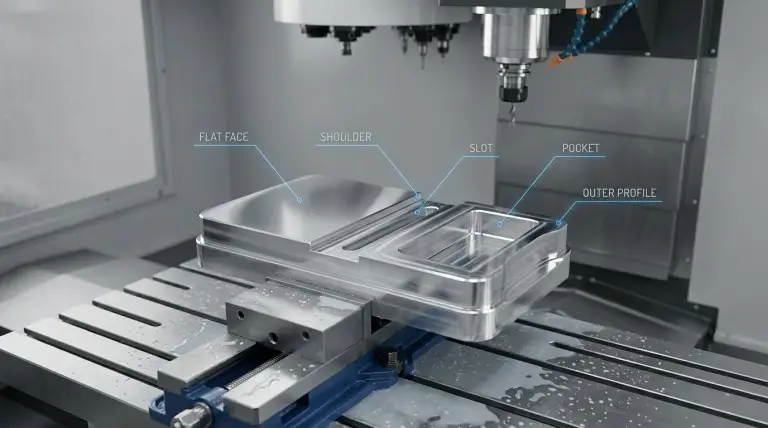

CNC milling uses programmed toolpaths and rotating cutters to remove material. The term “type” can refer to spindle orientation, axis capability, or machine architecture. Clear definitions prevent flawed comparisons between a machining center, a turret-style mill, and a router. A consistent selection process also helps avoid rework when a part moves from prototype to production.

Understanding CNC Milling Machine

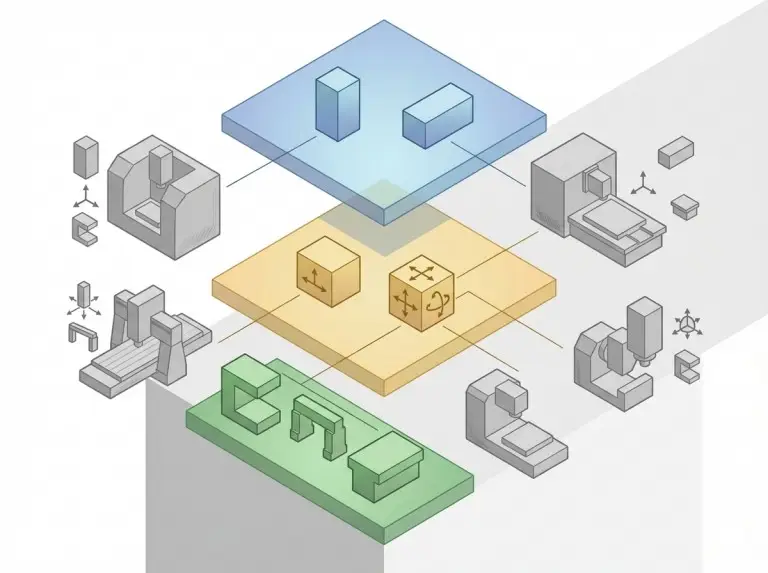

To reliably compare CNC milling machines, you must separate axis capability, spindle orientation, and machine architecture. Axis capability refers to the degrees of motion. Spindle orientation describes the tool’s approach direction. Architecture defines the machine’s structural stiffness and workspace. Each label impacts setup count, tool reach, and stability in unique ways.

Axis labels typically start with 3-axis (X/Y/Z) motion and add rotary axes for indexing or simultaneous tool movement. A 4th axis might index a part for multi-face work. A 5-axis machine could offer either positional (3+2) work or simultaneous 5-axis motion. Machine quotes should specify the intended motion mode, as the term “5-axis” can describe different production outcomes.

Spindle orientation labels distinguish vertical machining centers (VMCs) from horizontal machining centers (HMCs). A VMC offers top-down access, making it common for flat parts, plates, and molds. An HMC provides side access, allowing gravity to help with chip removal. This changes finishing behavior and automation options for multi-face jobs.

Architecture labels include platforms like bridge/gantry mills, traveling-column machines, and bed-type mills. Architecture has a greater impact on stiffness, thermal behavior, and the usable work area than axis count alone. It also affects your fixture strategy, as a table-moving machine behaves differently from a head-moving one during long-reach and heavy cutting.

Common Misconceptions in Machine Comparisons

CNC machine selection often fails when teams rely on a single headline label instead of a setup-based analysis. A 5-axis machine can be the wrong choice for a flat plate with simple features. Likewise, a 3-axis VMC may be unsuitable for a cubic part needing five machined sides with tight tolerances. A proper comparison begins with the number of setups needed to access all critical surfaces.

The idea that “more axes equal better accuracy” is a common myth. Accuracy depends on setup repeatability, probing strategy, fixture stiffness, and avoiding re-clamping—not just axis count. The main reason to invest in more axes is to reduce setups. You should verify if your part truly benefits from this.

Another error is thinking the choice between a vertical and horizontal machine is just a preference. Chip evacuation, tool access, and automation paths differ significantly between VMC and HMC platforms. These differences affect the stability of long production runs. Ignoring chip behavior often leads to finish or tool life problems later.

Main CNC Milling Machine Types and Their Uses

CNC milling machine types are most useful when paired with a typical part shape and setup pattern. The following list covers common platforms found in buyer searches and supplier catalogs. Each description includes a key constraint to verify during the quoting process.

Vertical Machining Center for Flat Parts

A vertical machining center (VMC) is ideal for parts machined mainly from one side that require frequent tool changes. VMCs are common for plates, brackets, and general prismatic parts where gravity doesn’t trap chips in deep pockets. With simple fixtures, setup time can be low for mixed prototype work.

However, a VMC can struggle with parts needing multiple faces machined to tight tolerances, as re-clamping increases risk. When selecting a VMC, verify the largest tool reach and deepest pocket features, since packed chips can ruin the surface finish if coolant is not effective. Your quoting package should note if probing, chip evacuation aids, or cleaning steps are part of the plan.

Horizontal Machining Center for Multi-Face Parts

A horizontal machining center (HMC) suits cubic or multi-face parts that benefit from gravity-assisted chip fall and easy multi-face access. HMCs often use tombstones or pallets to reduce non-cut time in batch production. They are common for housings, blocks, and parts requiring multiple sides machined from stable datums.

Investing in an HMC can be a waste for flat, one-sided work that doesn’t use its multi-face advantage. An HMC quote should be checked against the fixture and pallet strategy, as automation value depends on repeatable loading and stable datum transfer. You should also confirm the chip management plan for your target material.

Universal or Turret-Style CNC Mill for Angled Access

A universal or turret-style CNC mill is a good fit for short runs that require frequent angle changes and hands-on flexibility. These machines often have a head that tilts or rotates, allowing for intermediate angles without complex fixturing. Toolrooms use them for repairs, one-offs, and fixtures that change often.

A universal platform usually sacrifices rigidity and automation for flexibility. You should verify rigidity expectations by considering the longest planned tool overhang and the hardest material you will cut. A quote should also state whether the machine is for continuous production or occasional toolroom-style work.

Bed-Type and Knee-Type CNC Mills for 3-Axis Work

Bed-type and knee-type CNC mills suit general 3-axis milling where a traditional mill format is preferred. Bed-type designs often improve rigidity for heavier work by placing the table on a fixed bed and using the spindle head for Z-axis motion. Knee-type designs can have a smaller footprint and are flexible for shop use, sometimes mixing manual and CNC modes.

These platforms vary in stiffness and control integration, so the “bed-type” or “knee-type” label is not a performance guarantee. You should verify the table load, expected cutter engagement, and positioning performance as part of the acceptance criteria. The quoting process should also define if the mill is a retrofit, a light production machine, or a substitute for a machining center.

Bridge or Gantry Mill for Large Envelopes

Bridge, gantry, and portal mills are designed for large workpieces that need high stiffness across a wide area. This architecture often keeps the workpiece on a fixed bed while the tool head moves, which stabilizes large fixtures. Mold bases, large plates, and structural components are often machined on these platforms.

Large-envelope platforms can have practical limits in workholding and measurement. You should verify how the part will be clamped, probed, and inspected across the full travel range. A quote should also clarify how thermal stability and long-axis accuracy will be validated for your actual part size.

Traveling-Column Machining Center for Long Parts

A traveling-column machining center suits long parts where column motion provides reach without needing an oversized table. This architecture supports long travel while keeping fixtures practical. These machines are often found in shops that need flexibility for various part lengths.

Long-travel machines require careful checks for straightness and repeatability along the full axis. You should verify part support points, as long parts can distort if not supported correctly during cutting. A quoting package should define probing routines and reference strategies for long datum features.

CNC Router-Style Platform for Panels and Composites

A CNC router-style platform is ideal for sheet work, panels, and composite trimming where high-speed motion and large planar areas are important. This platform is common for plastics, wood, foam, and composites. Some setups can also handle aluminum with the right spindle and rigidity. Its key value is efficient 2D and 2.5D machining over large surfaces.

A CNC router should not be treated as a direct substitute for a rigid machining center for hard-metal milling. You should verify spindle power, tool holding, and rigidity for your specific material and tolerances. A quote should also define dust or chip extraction needs, as process stability depends on managing debris.

4-Axis and 5-Axis Machining Centers for Complex Access

Multi-axis machining centers are for parts where fewer setups reduce cumulative error and improve feature relationships. A 4th axis usually supports indexing for multi-face machining. A 5-axis platform can support either 3+2 positioning or full 5-axis simultaneous motion. These machines are most valuable for parts with compound angles or deep features that need the tool to tilt.

Multi-axis platforms introduce programming, verification, and collision risks that must be managed. You should verify whether your production plan needs 3+2 positioning or 5-axis simultaneous motion, as this affects cycle time, toolpath strategy, and inspection. A quote should also clarify post-processor, simulation, and probing needs for first-article validation.

Further reading:Most Common Types of CNC Machines

A Quick Comparison of CNC Milling Machine Types

Comparing CNC milling machines is clearer when you use decision variables instead of marketing labels. The table below summarizes the typical fit and what to watch out for with common platforms. Use the “verify” column for RFQs and internal reviews.

|

CNC Milling Machine Type |

Typical Best Fit |

Typical Advantage |

What to Verify Before Selecting |

|---|---|---|---|

|

VMC |

Flat parts, one-side access features |

Fast changeover for mixed work |

Chip packing risk in deep pockets, reach limits |

|

HMC |

Multi-face prismatic parts, repeat runs |

Chip fall and fixture automation |

Tombstone/pallet plan, datum transfer strategy |

|

Universal/Turret CNC |

Toolroom, angled one-offs |

Flexible angle access |

Rigidity under long tool overhang |

|

Bed/Knee-Type CNC |

General 3-axis work |

Familiar form factor, compact |

Control integration, stiffness, acceptance checks |

|

Bridge/Gantry/Portal |

Large parts, wide envelope |

Stiffness across big work area |

Workholding, probing, thermal stability |

|

CNC Router |

Panels, composites, trimming |

Large planar envelope, fast motion |

Material capability, extraction plan, realism |

|

4-Axis or 5-Axis Center |

Reduced setups, complex access |

Fewer clamps, better feature relations |

3+2 vs simultaneous mode, simulation plan |

Key Selection Factors for Your Purchase Decision

Your choice of a CNC milling machine becomes easier to defend when you use measurable constraints as your criteria. The most reliable criteria relate directly to part geometry, required surfaces, and the setup plan. This allows you to compare machines using the same job model rather than just brochure highlights.

Part geometry and access should be your first filter. A VMC often suits flat parts with top-side features. An HMC or multi-axis machine is often justified for cubic parts with many faces. Complex undercuts or compound angles may require a 5-axis machine, but only if the toolpath plan truly reduces setups.

Production intent should be defined as “high-mix vs. repeat-run.” High-mix prototype work values quick changeovers and simple fixtures. Repeat work values stable automation, consistent chip control, and reduced non-cut time.

Material and cutter engagement should guide your rigidity needs. Hard steels and heavy cuts demand stiffer architectures and stable workholding. Softer materials like aluminum may prioritize spindle speed and chip evacuation, but surface finish still depends on toolpath and coolant planning.

Quality verification should be part of the selection process, not an afterthought. Probe routines, datum definition, and inspection criteria determine if a machine can repeatedly meet your drawing’s intent. You should also confirm how many re-clamps the process will require to machine all toleranced features.

Verification Checklist for Quoting and Testing

Your CNC milling machine selection is safer when the purchase process includes questions tied to your intended jobs. The checklist below is for RFQs, supplier calls, and internal reviews. The goal is to align assumptions, not just rely on optimistic specs.

RFQ and Process-Definition Questions

- What part family and material define the baseline job?

- How many setups are required on each candidate machine?

- Is 3+2 positioning or 5-axis simultaneous motion required?

- What fixture concept will be used and how will datums be verified?

- What are the acceptance criteria for first-article inspection?

Practical Acceptance Questions

- Which probing routine will establish the work coordinate system?

- What tool holders and lengths are assumed for the baseline job?

- What chip evacuation and coolant strategy is planned?

- What simulation process is required for multi-axis work?

- Which inspection method will validate the most critical tolerances?

Conclusion

CNC milling machine types become practical decision tools when you connect machine labels to setups, datums, and chip behavior. A VMC, HMC, or gantry architecture can all be the right choice, but only if it matches a specific part family and workflow. The most dependable comparisons use the same baseline job and acceptance checks.

At Yonglihao Machinery, we treat machine selection as a process that starts with your drawings and critical features. Our CNC machining services support prototypes and short-run production, so we focus on reducing re-clamps and making verification steps clear. That setup-first approach also guides our cnc milling machine services, ensuring the machine choice supports your datums and verification plan.For a fast, defensible recommendation, we suggest building a simple job model and using a verification checklist before committing to a machine.

FAQ

What is the most common CNC mill for job shops?

A vertical machining center (VMC) is a popular choice for mixed prototype work and general 3-axis milling. It fits many flat parts and supports fast changeover. However, you still need to verify its chip control in deep pockets and its tool reach on tall features.

When is an HMC a better choice than a VMC?

An HMC is a better option when prismatic parts need multiple faces machined with stable datums. Gravity-assisted chip fall and tombstone fixturing can reduce manual work on repeat jobs. An HMC plan should be checked against your fixture strategy and pallet workflow.

Does “5-axis” always mean simultaneous motion?

A “5-axis” label can mean either 3+2 positional work or full 5-axis simultaneous tool motion. The outcome depends on the machine’s control, programming, and collision management. A quote should state the intended motion mode and why it’s needed.

Is a CNC router a type of CNC milling machine?

A CNC router can be considered a type of CNC mill when it removes material from panels or soft materials. Routers prioritize large work areas and high-speed motion over heavy metal-cutting stiffness. Verify its material capability and tolerance intent before using it as a substitute for a machining center.

What machine is best for large molds or plates?

Bridge, gantry, or portal architectures are often best for large workpieces that need stiffness across a wide area. This design usually supports fixed-bed workholding and stable access. A large-part plan should be verified for workholding, probing reach, and thermal stability.

What factor prevents the costliest “wrong machine” error?

Focusing on the setup count tied to critical datums is the most reliable selection factor. Fewer setups can reduce cumulative error, but only if fixturing and probing are planned early. Your selection process should verify how each platform machines the required surfaces with the fewest high-risk clamps.