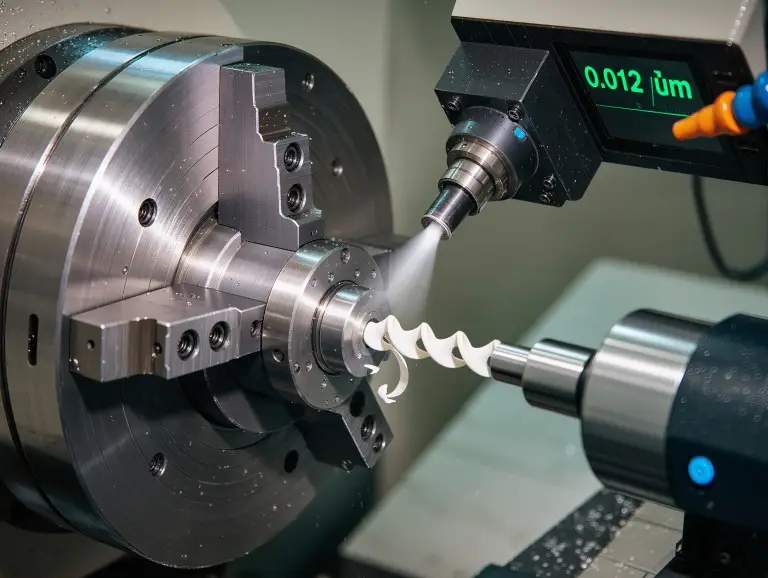

Boring is a key part of making mechanical parts. It directly affects how components fit and work. As a precision process, boring greatly improves hole quality. In precision engineering, a simple hole is more than just a hole. It meets exact standards through boring. This method uses rotating tools to remove material. It can achieve tolerances as tight as 0.001 inches. This is much better than standard drilling.

Boring machining is a precise hole-making technique. It is used to expand and finish existing holes. This creates high-precision sizes, shapes, and surface finishes. With the growth of CNC milling online and advanced digital platforms, access to high-quality boring and machining services is more convenient than ever. This article will explain its definition and how it differs from other methods. It will also cover its principles, types, tools, and parameters. We will look at its pros and cons, challenges, and uses. This will help readers understand the technology from basic to advanced levels.

What is Boring Machining?

The core of boring is using a tool to expand or finish existing holes. This ensures the hole has a precise diameter and a high-quality surface. Boring starts with holes made by drilling, casting, or forging. It uses a single-edge tool to remove material from the inner wall. This adjusts the hole’s size. The process requires precise control to avoid making flaws in the first hole worse. At Yonglihao Machinery, we often expand cast holes by over 20%. We keep the coaxiality error within 0.01mm.

Its main goals are to get precise hole sizes. It also aims to improve the hole’s straightness and roundness (geometric accuracy). Another goal is to create a better surface finish. Boring can control surface roughness to be below Ra 0.8μm. This improves how long a part lasts. This not only helps parts fit together better but also reduces future wear. For example, when working with aluminum alloy parts, it ensures the hole is symmetrical. This prevents problems during assembly.

Differences Between Boring and Other Machining Methods

Boring is different from other machining methods. It focuses on finishing existing holes. It does not create new holes or machine external surfaces. This helps users avoid confusion. By comparing methods, we can show boring’s unique role. This ensures the right process is chosen.

Boring vs. Drilling

The main difference between boring and drilling is their function. Drilling creates the first hole from nothing. Boring adds the final touch to fix and expand existing holes. Drilling uses multi-edge drill bits to remove material quickly. Its tolerances are usually around 0.02 inches. The surface is often rough and can be off-center. Boring uses single-edge tools to get 0.0005-inch tolerances. It is good for jobs that need high precision. For instance, in our projects, boring right after drilling can fix initial errors. This improves the overall accuracy.

Boring vs. Reaming

The difference between boring and reaming is their capability. Reaming mainly adjusts the size and finish slightly. It cannot fix major hole-positioning errors. Boring, however, can remove more material and correct the hole’s geometry. Reaming uses multi-edge tools. It is only for holes that are already close to their final size. Its tolerance is about 0.001 inches. Boring can fix holes that are off-center, expand their diameters, and improve their alignment. In our work, we often use boring for the main adjustment. Then we use reaming for the final finish. This ensures the surface finish reaches Ra 0.8μm.

Boring vs. Turning

Boring is like “internal cylindrical turning.” It differs from turning, which machines external surfaces. In boring, the workpiece is usually still (on a milling or boring machine). Or, the tool is still (on a lathe). Turning spins the workpiece to remove material from its outer surface. Boring focuses on inner holes, with the tool spinning and feeding. This makes boring ideal for inner precision, like in cylinder holes. In our shop, we often use lathe boring for cylindrical parts. This helps reduce vibration.

|

Machining Method |

Main Function |

Tool Type |

Typical Tolerance |

Applicable Scenarios |

|---|---|---|---|---|

|

Boring |

Refine existing holes, expand diameter, correct geometry |

Single-edge tool |

0.0005 inches |

Precision components, such as cylinder holes |

|

Drilling |

Create initial holes |

Multi-edge drill bit |

0.02 inches |

Fast rough machining |

|

Reaming |

Fine-tune size and finish |

Multi-edge tool |

0.001 inches |

Holes near final size |

|

Turning |

External machining |

Fixed tool |

Depending on the situation |

Cylindrical outer surfaces |

Working Principles and Process Flow of Boring Machining

The working principle of boring is based on motion. The tool and workpiece move relative to each other. This allows for precise material removal. The process flow has several steps. These steps ensure a gradual improvement from rough to fine.

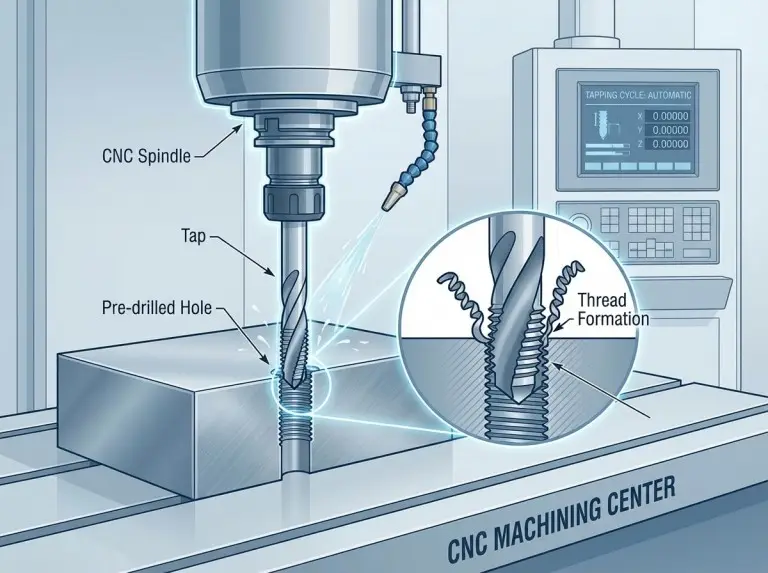

Basic Working Principle

The basic principle is simple. The cutting tool spins around the hole’s axis. At the same time, it feeds forward along the axis. Its single edge cuts the inner wall material. This expands the hole’s diameter. This relative motion ensures material is removed evenly. It also prevents uneven stress. The tool is designed for a precise interaction with the workpiece. This allows for accurate material removal. There are different methods, like those for lathes and milling machines. The choice depends on specific needs. For example, in lathe boring, the workpiece spins. In milling machine boring, the tool spins. This is good for complex shapes. We find the milling machine method is more flexible. It works well for non-symmetrical parts and reduces errors.

Main Steps of Boring Machining

The main steps include clamping, pre-machining, rough boring, and finish boring. These steps ensure both efficiency and high quality. Here is a numbered list:

- Workpiece Clamping: Positioning and fixing the part is important. It ensures the part is aligned with the machine’s axis. Any misalignment will increase errors. We use precision fixtures to control errors within 0.01mm.

- Pre-Machining: This ensures there is a hole to start with (from drilling or casting). This step provides the initial dimensions. It avoids having to start from a solid piece.

- Rough Boring (Roughing): This step quickly removes a lot of material. It also corrects the straightness of the hole. We use higher feed rates to get close to the final size.

- Finish Boring (Finishing): This step uses a low feed and high speed. It achieves the final tolerances and surface quality. This step focuses on precision. It can achieve a surface finish below Ra 0.8μm.

In our aerospace projects, we optimized these steps. This reduced surface roughness from Ra 1.6μm to Ra 0.8μm.

Main Types of Boring Machining

The main types of boring are based on the machine and the process. They meet different needs and precision levels. Using vertical, horizontal, and specific processes covers all needs.

Here is a table of the types:

|

Type |

Subcategory |

Applicable Scenarios |

Advantages |

|---|---|---|---|

|

By Machine |

Vertical Boring |

Large heavy workpieces (such as turbine casings) |

High stability, reduce gravity impact |

|

By Machine |

Horizontal Boring |

Long hole machining (such as engine cylinders) |

Strong flexibility, high precision |

|

By Machine |

CNC Boring |

Batch production |

±0.0005 inches tolerance, automation |

|

By Process |

Line Boring |

Coaxial hole correction (such as crankshaft holes) |

Precise alignment |

|

By Process |

Back Boring |

Internal feature machining |

Avoid external interference |

Classification by Machine Type

Boring is divided into vertical, horizontal, and CNC types by machine. Each has its own best use.

- Vertical Boring: This is good for large, heavy workpieces. The workpiece spins, which provides stability. It is suited for big parts like turbine casings. It also reduces the effect of gravity.

- Horizontal Boring: This is suited for machining long holes. The tool rotates, offering great flexibility. It is often used for engine cylinders and provides high precision.

- CNC Boring: This is an automated, high-precision process. It is controlled by a program. It can reach a tolerance of ±0.0005 inches. This makes it ideal for making many parts at once.

Classification by Machining Process

Processes include line boring and back boring. These target specific hole structures.

- Line Boring: This is used to correct aligned holes at both ends. An example is the crankshaft holes in an engine. It ensures precise alignment and improves durability.

- Back Boring: This process expands a hole from the back. The tool passes through the hole first. It is good for internal features. It helps avoid interference from the outside.

- Blind Hole Boring vs. Through Hole Boring: Blind holes need careful chip removal. Through holes let tools pass all the way through. Different strategies are used to prevent warping.

- Precision Boring & Jig Boring: Precision boring aims for high accuracy. Jig boring is for jobs with very strict positioning needs.

Tools and Equipment Required for Boring Machining

The tools and equipment for boring include machines and tool parts. They ensure the process is precise and efficient. Choosing the right equipment depends on the workpiece size, material, and required precision.

Common Machine Tools

Common machine tools include lathes, milling machines, and dedicated boring machines. Each offers unique functions. Lathes spin the workpiece around a fixed axis. They create precise holes and remove material. They are often used for cylindrical inner holes. Milling Machines spin the tool around the workpiece. They are very versatile and good for complex shapes. In our workshop, we often use lathes for simple inner holes. We use milling machines for irregular parts. Dedicated boring machines are made for high-precision holes. They can support large workpieces.

Tool Components (Tooling)

Tool components include boring bars, boring heads, and inserts. Your choice affects rigidity and cutting performance. Boring bars are the main part. Their material, like steel, carbide, or damping bars, affects stability. A long bar can cause vibration. Boring heads are precise tools for adjusting the hole diameter. They support fine adjustments and improve efficiency. Inserts are the cutting part. The material (like tungsten carbide) and shape depend on the material’s hardness. For example, by using damping boring bars, we reduce vibration by 20% in deep hole work.

Here is a summary of tool components:

|

Component |

Description |

Key Influencing Factors |

|---|---|---|

|

Boring Bar |

Holds the cutting tool |

Material, length-to-diameter ratio, rigidity |

|

Boring Head |

Adjustable diameter mechanism |

Fine adjustment precision, versatility |

|

Insert |

Actual cutting part |

Material, geometric shape |

Key Machining Parameters and Influencing Factors

Key machining parameters include cutting speed, feed rate, and depth of cut. These directly affect efficiency and quality. Factors like the length-to-diameter ratio and rigidity must be managed. This helps avoid common problems.

Cutting Parameters

The core cutting parameters are cutting speed and feed rate. They balance efficiency with the final finish. A high cutting speed might improve the finish but wears the tool faster. The feed rate affects how fast material is removed. The depth of cut is larger in rough boring for quick removal. It is smaller in finish boring to ensure precision. For example, on carbide materials, a slower feed rate can extend tool life by 15%. Optimizing these parameters can reduce surface roughness to Ra 0.8μm. In our projects, adjusting the speed shortened production time by 10%.

Key Factors Influencing Quality

Key factors affecting quality include the length-to-diameter ratio (L/D Ratio). This is the most important factor and determines tool stability. A ratio over 4:1 can easily cause vibration. This leads to a rough surface. Machine and workpiece rigidity also help avoid vibration. Precision fixtures can make them stronger. Chip removal and cooling are also important. This is especially true for blind holes to prevent heat damage. Using coolant can reduce heat buildup and improve tool life.

Here is a list of influencing factors:

- Length-to-Diameter Ratio: Keep it below 4:1 to reduce tool bending.

- Rigidity: Improve how the machine and workpiece are held to reduce vibration.

- Chip Removal and Cooling: Manage chips well to avoid clogs and overheating.

|

Parameter/Factor |

Description |

Typical Value/Range |

Influence |

Optimization Suggestions |

|---|---|---|---|---|

|

Cutting Speed |

Tool rotation speed |

Depending on material |

Improve finish, but accelerate wear |

Reduce by 20% on carbide materials |

|

Feed Rate |

Axial feed |

Higher in rough boring, lower in finish boring |

Material removal rate |

Reduce to extend tool life |

|

Length-to-Diameter Ratio |

Tool length/diameter |

<4:1 |

Stability, avoid vibration |

Keep below 4:1 |

|

Rigidity |

Machine/workpiece fixing |

– |

Reduce vibration |

Use precision fixtures |

Advantages, Disadvantages, and Challenges of Boring Machining

The pros and cons of boring lie in balancing its high precision with its challenges. Vibration is one such challenge. Understanding these helps you decide when to use it.

Advantages of Boring

Boring’s advantages include very high accuracy for hole diameters. It also creates excellent hole straightness and alignment. It can achieve 0.001-inch tolerances. This is perfect for parts that must fit tightly. It can machine large-diameter holes that are hard for other tools. An example is large cylinder holes. Its excellent alignment reduces assembly failures by 15%.

Limitations and Challenges

Limitations and challenges include tool bending and vibration. Vibration is the biggest problem caused by long tool overhangs. The machining cycle is slower than drilling and reaming. It takes more time. The costs are also higher. It requires skilled operators and specific equipment. Solutions include using damping bars or adjusting parameters to fix vibration. For example, you can reduce the feed rate. In our work, these methods have reduced vibration problems to below 10%. Despite these challenges, boring is essential in precision fields.

Here is a table of challenges and solutions:

|

Challenge |

Description |

Solution |

|---|---|---|

|

Vibration |

Caused by long overhang |

Damping bars, optimize parameters |

|

Low Efficiency |

Long cycle |

CNC automation |

|

High Cost |

Requires skilled workers and equipment |

Training and equipment upgrades |

Typical Application Fields of Boring Machining

Boring is typically used in the automotive, aerospace, and heavy machinery fields. It ensures the production of precision components. In these industries, it handles complex holes and improves performance.

- Automotive Industry: It is used for engine cylinders and transmission housings. It ensures pistons fit precisely and improves efficiency by 10%.

- Aerospace: It is used for landing gear parts and turbine casings. It creates high-precision shapes that can handle extreme conditions.

- Heavy Machinery: It is used for excavator booms and large bearing seats. It provides accurate hole positions to improve heavy-load capacity.

Conclusion

Boring machining cannot be replaced in precision manufacturing. It provides high-precision solutions for making holes. Choosing the right tools and parameters is the key to success. This ensures both quality and efficiency.

This process is super accurate, with errors as low as 0.001 inches. It also provides a fine surface finish, as low as Ra 0.8μm. This makes it vital for industries that need top-level parts. We have discussed its definition, differences, and principles. We also covered its types, tools, parameters, pros and cons, and uses. This shows how versatile boring is. It can handle tasks from simple to complex.

At Yonglihao Machinery, we have been experts since 2010. We focus on making rapid manufacturing. We provide CNC machining services and more, which support boring. Our team’s skills ensure top quality. Contact us to see how we can help with your needs.

FAQ

What is Boring Machining?

Boring is a precision process. It uses a boring tool to expand or finish existing holes. These holes may be from drilling, casting, or forging. Its main goals are to get precise hole sizes. It also improves the straightness, roundness, and geometry of the hole. It enhances the surface finish, reaching tolerances as low as 0.001 inches.

What are the Differences Between Boring Machining and Other Machining Methods?

Boring focuses on finishing existing holes. This is different from drilling, which creates the first holes. It is also different from reaming, which only fine-tunes size and cannot fix errors. Turning works on external surfaces. For example, boring can remove more material and fix geometry. Drilling tolerances are usually around 0.02 inches. The choice depends on the need. In our projects, drilling first then boring can greatly improve accuracy.

What are the Main Steps of Boring Machining?

The main steps are clamping the workpiece to ensure alignment. Then comes pre-machining to prepare the initial holes. Rough boring quickly removes material and corrects straightness. Finish boring uses a low feed and high speed. It achieves the final tolerances and surface quality. Optimizing these steps can reduce errors.

How to Solve Common Challenges in Boring Machining?

Common challenges include vibration and tool bending. These are often caused by a long tool length. They can be solved by using damping bars. Optimizing cutting parameters, like reducing the feed rate, also helps. Effective cooling is another solution. These fixes can extend tool life by 15% and improve efficiency.

Which Industries is Boring Machining Suitable For?

It is suitable for the automotive industry for parts like engine cylinders. It is also used in aerospace for turbine casings. Heavy machinery, such as for excavator booms, also uses it. It provides high-precision hole machining for these fields.