When comparing brass vs bronze vs copper, choosing between these metals seems simple at first. However, real mistakes happen when people ignore service conditions. Conductivity targets, corrosion chemistry, and sliding wear decide the outcome.

At Yonglihao Machinery, we see selection errors. Teams pick a metal for one advantage only. For example, a fast-machining brass can fail in a salty, stressed assembly. Additionally, a high-conductivity copper can deform or gall in contact.

This guide stays practical. We link each material family to properties that control part life. Then, we map you to common grades used in custom manufacturing.

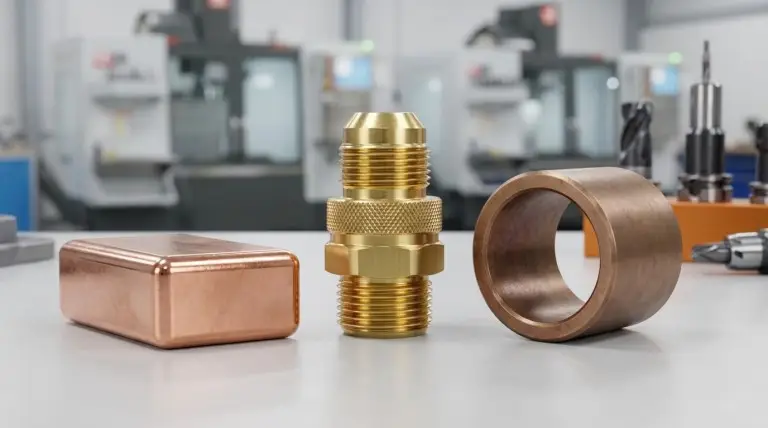

What Are Copper, Brass, and Bronze?

Copper is a base metal. Brass and bronze are copper-based alloys. They look similar. But the main alloying elements change performance.

Brass is mainly copper plus zinc. Zinc raises strength. It improves machinability. It lowers conductivity compared to copper. Brass varies widely by grade. So “brass” is never one behavior.

Bronze is copper plus other alloying elements. It started with tin. Many bronzes target wear resistance. They also target corrosion performance. This fits marine or sliding-contact service. Some bronzes trade ease of machining for strength and durability.

A useful first filter is simple. Copper starts when conductivity is key. Brass starts when machining speed and cost balance matter. Bronze starts when wear or harsh corrosion controls service life.

Nevertheless, that filter is not the final answer. Grade, temper, and product form change behavior a lot. Product forms include wrought, cast, or forged. The “right” choice matches failure mode, environment, and manufacturing route.

Main Types of Copper, Brass, and Bronze Alloys

C10100 (Oxygen-Free Copper)

People choose C10100 when purity and electrical performance are top priorities. It is common in high-end electrical, electronics, and vacuum-sensitive work. It forms well. It can be machined. But it stays soft.

We treat C10100 as a conductor first. It is not a wear surface. Under contact stress, pure copper can deform or gall. Therefore, if sliding contact exists, the design needs geometry changes or surface protection.

C11000 (ETP Copper)

C11000 (ETP) is a common “workhorse” copper for conductors. It supports bus bars, connectors, grounding parts, and general electrical hardware. Availability is strong. Behavior is predictable.

For custom parts, C11000 is often the fastest path to stable delivery. If the assembly needs welding or high-heat joining, we check the joining plan early. Oxygen content can matter with certain processes and temperatures.

C12200 (DHP Copper)

C12200 is phosphorus-deoxidized copper. It fits tubing and piping service. People select it when brazing or welding consistency matters. It performs well in plumbing-like applications, manifolds, and fluid transport parts.

The trade-off is lower electrical conductivity than oxygen-free grades. We treat C12200 as a “reliable fabrication copper.” It is not a “maximum conductivity copper.” If the part is an electrical path, confirm the conductivity requirement before locking it in.

C26000 (Cartridge Brass)

C26000 is a classic brass. People use it for cold-formed parts and clean appearance. It balances strength and ductility well. This supports stamping, bending, and formed hardware. It also fits panels and decorative sheet components where formability matters.

We do not treat all brass as equal in corrosive environments. Chlorides, ammonia, and sustained stress can raise stress-corrosion risk in some brasses. If the assembly sees salty moisture plus stress, screening the environment is part of responsible selection.

C36000 (Free-Cutting Brass)

C36000 is a top choice for free-machining brass in CNC turning. It cuts cleanly. It controls chips well. It supports stable cycle times. For fittings, valves, and small precision parts, it can be very cost-effective.

The main constraint is compliance. If the part touches drinking water or regulated consumer products, lead-free rules may apply. When compliance matters, we redirect the grade before you invest in tooling.

C37700 (Forging Brass)

C37700 is designed for hot forging and high-volume shaping. It is a common fit for fittings and valve bodies where forging efficiency matters. It can reduce the machining needed to achieve near-net shape.

If your route is strictly CNC from bar stock, C37700 may not be the best value. We match the alloy to the manufacturing route. We do not do the other way around. As a result, that keeps cost and quality stable across production.

C46400 (Naval Brass)

People use C46400 when they want a more reliable brass for marine exposure. It fits hardware exposed to salty air, splashing, and coastal conditions. It is a practical upgrade over general-purpose brasses when corrosion risk is real.

“Marine” is not one condition. Stress level, crevice design, and chemical exposure decide service life. We treat C46400 as a strong candidate. It still needs verification against the real environment.

C69300 (Lead-Free Brass)

C69300 is a lead-free brass. People use it for regulated, water-contact applications. It is common in plumbing components, valves, and hardware where compliance is mandatory. It helps meet lead-free requirements. It retains useful strength.

Compared to free-cutting brasses, machining behavior can change. Tool wear, chip control, and surface finish may need adjustment. Therefore, we plan feeds, tooling, and tolerances around the grade. This keeps production stable.

C93200 (Bearing Bronze)

C93200 is a bearing-focused bronze. People use it for bushings, thrust washers, and sliding parts. It is valued for wear behavior and embedability. It tolerates imperfect lubrication and small debris better than many alternatives.

We do not treat it as a universal bronze. Its best fit is non-pressure, sliding-contact service where controlled friction is the goal. Thus, if the part is structural or pressure-bearing, verify the mechanical requirements first.

C91000 (Tin Bronze)

C91000 is a tin bronze. People use it for tougher, heavy-duty components. It fits pump-related parts and machinery components where wear resistance and strength both matter. People select it for repeated loading and high-stress sliding contact.

If conductivity is the priority, copper grades usually win. However, if wear and mechanical stability control failure, C91000 is often the better starting point. Machining is more demanding than easy-cut brasses. So plan the process accordingly.

C95400 (Aluminum Bronze)

C95400 is an aluminum bronze. People choose it for harsh service with high loads. It offers a strong mix of mechanical strength and corrosion resistance. It appears in heavy-duty industrial components, marine-related equipment, and demanding environments.

Machining can be more challenging than brass. Tooling strategy and heat control matter for surface finish and edge life. Therefore, we align production plans early. This avoids rework and inconsistent surfaces.

Key Property Differences That Decide Performance

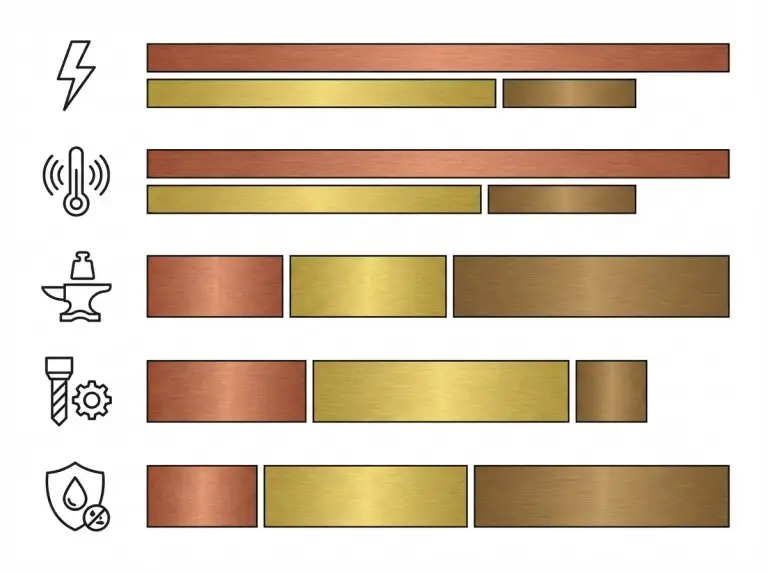

People summarize these three material families this way: copper conducts, brass machines, bronze wears. That is directionally true. But grade and condition control the final result. So, use the trends below to triage. Then, confirm with the specific grade.

Copper is the benchmark for electrical conductivity. Brass sacrifices conductivity to gain machinability and cost balance. Bronze targets wear resistance and corrosion performance, especially in seawater service.

Strength and hardness trends matter. Pure coppers are softer. They can deform under contact stress. Many bronzes offer higher strength and better wear resistance. Meanwhile, brasses sit in the middle depending on grade.

| What you care about | Copper (typical trend) | Brass (typical trend) | Bronze (typical trend) |

|---|---|---|---|

| Electrical conductivity | Highest | Lower than copper | Often lower than copper |

| Thermal conductivity | Usually high | Moderate | Grade-dependent |

| Strength & hardness | Lower to moderate | Moderate | Moderate to high (by family) |

| Machinability | Can be “gummy” | Often best (esp. C36000) | Moderate to challenging |

| Wear / sliding contact | Needs design help | Light to moderate duty | Often best (bearing bronzes) |

| Corrosion in marine exposure | Often good | Varies by grade | Often best for seawater |

This table is a decision aid. It is not a guarantee. Wrought vs cast condition can shift strength, ductility, and machinability. A “good” alloy in the wrong condition can fail.

To speed selection, map your application to the most common starting points. This prevents overpaying for performance you do not need. It also prevents choosing a “cheap” grade that creates rework.

| Application need | Typical starting family | Common starting grades (examples) |

|---|---|---|

| Bus bars, conductors, heat spreaders | Copper | C10100, C11000 |

| Tubing, manifolds, brazed plumbing-like parts | Copper | C12200 |

| High-throughput CNC turned parts | Brass | C36000 (or lead-free alternative) |

| Hot-forged fittings and valve bodies | Brass | C37700 |

| Marine hardware, salty air exposure | Brass / Bronze | C46400 (brass), C95400 (bronze) |

| Bushings, thrust washers, sliding wear | Bronze | C93200, C91000 |

| High load + harsh industrial corrosion | Bronze | C95400 |

Manufacturing Reality: Machining, Joining, Forming, and Process Route

Machinability is not just “can it be cut.” It is chip control, tool wear, heat management, and surface finish stability. Free-cutting brass can dominate cycle time. Copper may smear. It requires different strategies.

Joining changes the decision. Some copper grades are chosen because brazing and welding are predictable. Brass and bronze can be joined. However, grade chemistry and heat input can drive cracks, porosity, or weak joints.

Formability matters when stamping or bending is the process. A grade that cold-forms well can lower total cost versus machining. Therefore, this is why we match the alloy to the route early. We do not do it after the drawing is frozen.

Process route affects properties more than many teams expect. Wrought products differ from cast products in grain structure and consistency. Forged brasses can be stronger than cast brasses. Additionally, some cast options are poor fits for high-wear requirements.

Compliance is a real constraint. It is not a footnote. If the part touches drinking water or regulated consumer environments, lead-free requirements can control the alloy choice. So, if compliance is unclear, treat it as a requirement until proven otherwise.

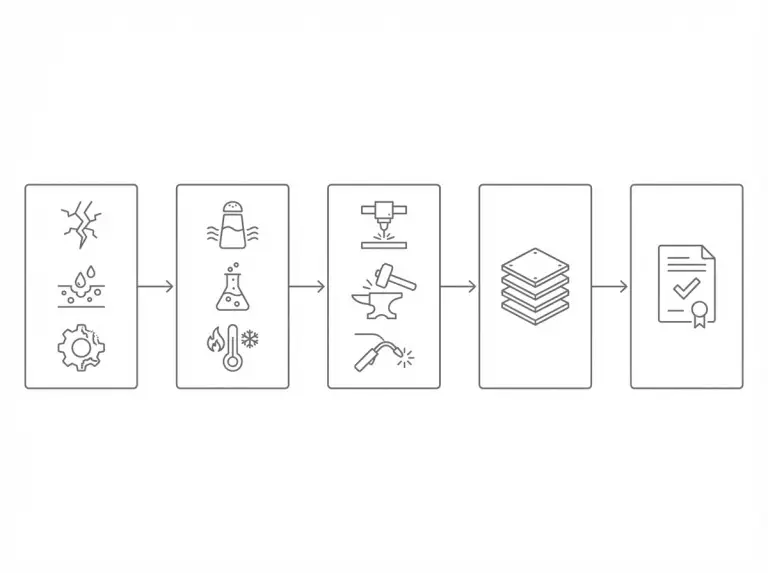

How to Choose: A Practical Selection Workflow for Your Project

The fastest way to choose is to identify what will fail first. Is it conductivity loss, corrosion, sliding wear, or manufacturing instability? The correct alloy family becomes obvious once failure mode is explicit.

Start by writing down three inputs. Define environment: salt spray, immersion, chemicals, humidity. Define loading mode: static load, cyclic load, sliding contact, impact. Define manufacturing route: CNC, forging, forming, brazing/welding.

Then, set your priorities. If conductivity is non-negotiable, start with copper. Pick the grade that fits joining and purity needs. If cycle time and finish control cost, start with brass. Confirm compliance requirements.

If the part lives in sliding contact, start with a bronze family designed for wear. If the environment is harsh and loads are high, aluminum bronze options are more defensible. However, if the duty is lighter, a brass might be enough with correct design.

Finally, verify the choice before production. Confirm the exact grade, temper/condition, and product form: bar, plate, casting, forging. Ask for material certification when the application is critical.

Conclusion

Copper is the start for conductivity. Brass is the start for machining efficiency and cost balance. Bronze is the start for wear and harsh corrosion.

The final choice comes from grade, environment, and manufacturing route. Anchor your decision to how the part fails in service. Do not rely on looks or a generic datasheet alone.

When considering brass vs bronze vs copper, if you share your environment, loading mode, and joining plan, we can shortlist one or two grades. That prevents wrong trade-offs before metal is cut.

FAQ

Which is best for electrical parts?

Copper is the best choice for electrical parts. It offers the highest electrical conductivity. Grades like C10100 or C11000 cover most needs. Brass and bronze can work in terminals. But they are chosen for machining or wear reasons.

Which is better for seawater and marine exposure?

Bronze is the safer start for seawater exposure. Many bronzes handle marine corrosion well. This includes aluminum bronze families. Naval brass can also perform in marine hardware. But stress level and crevice design matter.

Which is easiest to CNC machine?

Brass is the easiest for high-speed CNC machining. Free-cutting brass like C36000 produces controllable chips. It gives stable cycle times. Copper can be soft and “gummy.” Many bronzes need stronger tooling and tighter heat control.

Which is best for bushings and bearings?

Bearing bronzes are the best choice for bushings and bearings. Grades like C93200 are designed for sliding wear, embedability, and imperfect lubrication. Brass can work in light-duty cases. But true bearing bronzes are more defensible for long life.

How do I avoid choosing the wrong grade?

You avoid the wrong grade by locking the failure mode first. Decide whether conductivity, corrosion, wear, or compliance controls the design. Then match the grade family to the environment and manufacturing route. Verify grade plus condition before production.