Powder Coating Services

Yonglihao Machinery offers powder coating services for metal parts that need durable protection and a consistent appearance. Powder coating provides a tough, uniform film with a wide range of color options, making it ideal for both corrosion resistance and cosmetic finishes.

- Durable coating for corrosion and abrasion resistance

- Wide color options

- Matte to high-gloss finishes for various design goals

- Cost-effective for production parts and assemblies

What Is Powder Coating?

Powder coating is a dry finishing process where electrostatically charged powder is applied to a surface and cured to form a continuous protective film. Compared to liquid paint, it offers better film build, excellent coverage, and a more consistent appearance.

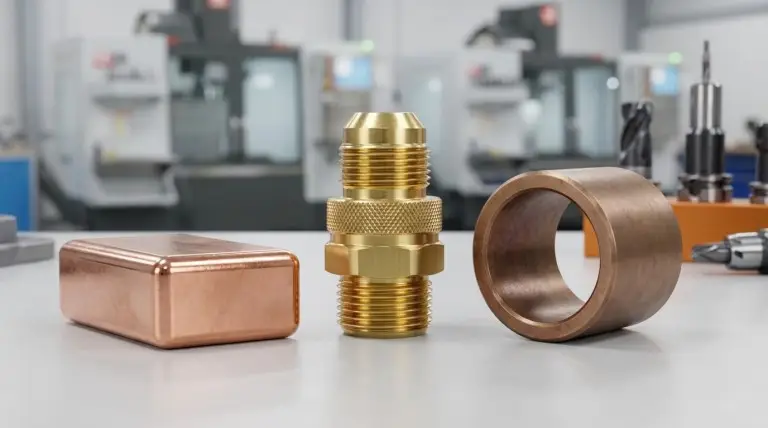

This process is primarily used on metals like steel and aluminum. Other substrates, such as magnesium, certain polymers, and composites, require strict process control and are reviewed on a case-by-case basis.

One-Stop Manufacturing

We can perform powder coating as a downstream step for parts made through:

Surface Preparation & Final Appearance

Powder coating follows the base surface condition. Deep scratches, dents, pits, and weld spatter will remain visible, especially under glossy finishes. If appearance is critical, consider bead blasting, sanding, or other surface preparation before coating.

For fit-critical parts, note that powder coating adds thickness, which can affect assembly. Threads, tight bores, and sealing faces are often masked to maintain functionality.

| Surface Preparation | Colors | Glossiness | Typical Thickness | Notes |

|---|---|---|---|---|

| As-machined / prepped as required | White, black, RAL (common), Pantone (by request) | Matte to high-gloss (target-defined) | 50–150 μm (typical) | Mask critical fits; glossy finishes highlight defects more |

FAQ

What materials can be powder coated?

Most commonly steel and aluminum. Other substrates are reviewed case by case.

How thick is powder coating?

Typically 50–150 μm, depending on performance and appearance requirements.

Will powder coating hide scratches and dents?

Not completely. Deep defects remain visible, especially under glossy finishes.

Does powder coating affect dimensions?

Yes, it adds thickness. Mask threads, bores, seal faces, and critical fits as needed.

Can you do specific colors like RAL or Pantone?

Yes. RAL is common. Pantone matching should be confirmed with a sample.

What finish can I choose?

Options range from matte to high-gloss. Define your gloss target if appearance is critical.

What do you need for a fast quote?

We need the material, quantity, part size, color, gloss target, thickness requirement, masking areas, and lead time.