Polishing Services

Yonglihao Machinery offers polishing services to enhance surface smoothness, gloss, and overall appearance for both functional and cosmetic parts. Polishing is ideal for achieving a cleaner reflection, lower roughness, or a premium “finished” look on visible surfaces.

- Smoother surface and higher gloss

- Improved cosmetic appearance for customer-facing parts

- Targeted polishing for specific faces or features

- Suitable for prototypes, small batches, and cosmetic-critical builds

Home » Surface Finishing Service » Polishing Services

What Is Polishing?

Polishing is a surface finishing process that uses abrasive media and polishing compounds—applied by machine or hand—to reduce surface roughness and increase brightness. Depending on the target, polishing can range from a light sheen to a high-gloss finish.

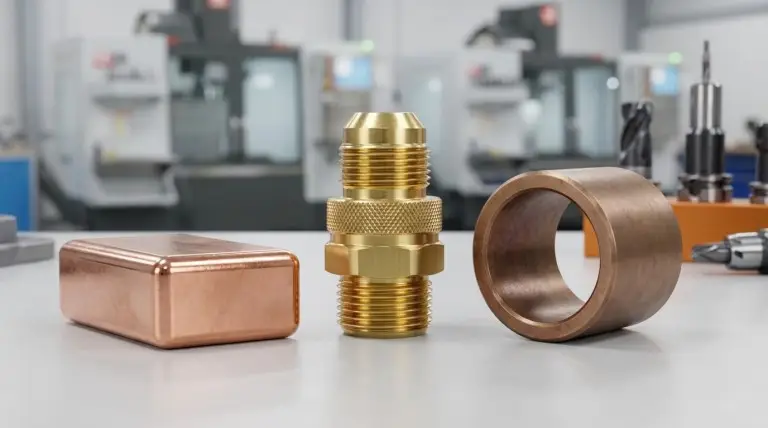

This process is commonly applied to aluminum, stainless steel, and copper alloys. It can also be used on selected plastics upon review. The final result depends on the material’s hardness, starting surface condition, part geometry, and the specified finish level.

One-Stop Manufacturing

We can perform polishing as a downstream step for parts made through:

Surface Preparation & Final Appearance

Polishing enhances brightness and smoothness but does not automatically remove deep dents, pits, or heavy surface damage without significant material removal. A better starting surface leads to more consistent polished results.

For the best outcomes, specify:

- Polished faces: Indicate which surfaces need polishing.

- Finish target: Choose between satin, semi-gloss, or high-gloss finishes.

- No-touch zones: Mark threads, tight fits, seal faces, or sharp edges that must remain untouched.

| Starting Surface | Applicable Materials | Finish Range | Visual Appearance | Notes |

|---|---|---|---|---|

| As-machined / cleaned | Aluminum, stainless steel, copper alloys (plastics by review) | Satin → high-gloss | Reduced tool marks, smoother reflection | Higher gloss requires more steps and time |

FAQ

What materials can be polished?

Most commonly aluminum, stainless steel, and copper alloys. Plastics are reviewed case by case.

Can you achieve a mirror finish?

Yes, in many cases. The result depends on the material and starting condition. Define the target and polished faces.

Will polishing remove scratches?

It reduces light scratches and machining lines. Deep defects may remain unless more material is removed.

Does polishing change dimensions?

It can, especially on edges and tight features. Mark critical fits and no-touch areas.

Can you polish only one face?

Yes. Targeted polishing is common for cosmetic panels and visible surfaces.

What do you need for a fast quote?

We need the material, quantity, part size, faces to polish, finish target, critical areas to protect, and lead time.