Metal Stamping Services

Home » Metal Stamping Services

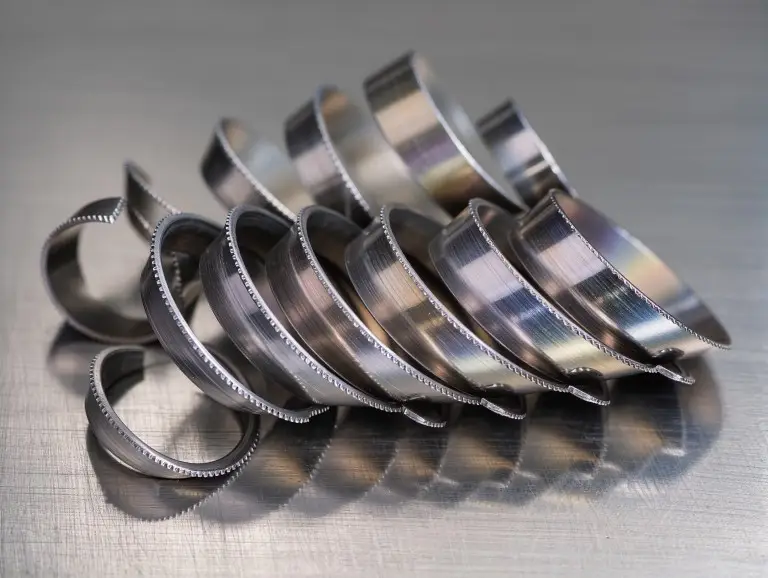

Metal Stamping Capabilities

As a leading stamping parts manufacturer, Yonglihao Machinery designs and produces stamped metal parts using materials like stainless steel, copper, and aluminum. The choice of material depends on the product’s design, function, and environment. Our designers also consider cost and performance to recommend the best stamping method. This ensures the process aligns with your budget, manufacturing needs, and final product requirements.

Why do you need metal stamping?

Metal stamping is essential in modern manufacturing. Many customers prefer this method because it is efficient, precise, and offers great design flexibility. It also maximizes material use, making it ideal for industries like automotive, electronics, and medical.

High Efficiency

Yonglihao Machinery customizes molds in advance, allowing us to quickly shape metal materials with precision. This process is faster than traditional methods, supporting large-scale production. As a result, it improves efficiency and lowers costs. For example, high-efficiency stamping can cut production time by over 50%.

High Accuracy

Large-scale production doesn’t compromise accuracy. Yonglihao Machinery integrates advanced control systems with precise molds to ensure every part meets strict engineering standards. This is especially important in industries like automotive and electronics, where precision is critical.

High Material Utilization

Compared to cutting, metal stamping manufacturing reduces material waste, significantly lowering costs in high-volume production. In one aviation project, our stamping process reduced the waste rate from 20% to 5%. This not only saves money but also supports sustainable manufacturing practices.

Flexibility

Metal stamping services allow for custom parts in various shapes and sizes using different molds. This flexibility makes it an ideal solution for many industries. For instance, we designed adaptable molds for a home appliance client, enabling quick design changes and faster time to market.

Key Steps in Custom Metal Stamping

The quality of stamped parts depends on the steps involved in the process. Choosing a reliable metal stamping company is crucial. At Yonglihao Machinery, we ensure every step is executed with precision, earning the trust of hundreds of enterprises.

1/Design Phase

This phase lays the foundation for the stamping process. Key factors like material, shape, and size are determined here. Based on this data, we design molds and collaborate with customers to conduct 3D simulations. This ensures the design is feasible and helps identify potential issues early.

2/ Mold Manufacturing

Mold manufacturing is the core of the process. High-quality molds ensure the accuracy of the final product. This step includes mold making, finishing, heat treatment, and surface treatment. Using CNC technology, we create molds with an average lifespan exceeding 100,000 stampings, reducing maintenance costs.

3/ Stamping Steps

The stamping process involves mold assembly, material loading, stamping, inspection, and unloading. Stability and accuracy are key to product quality. We use real-time monitoring systems to ensure zero defects in every batch and provide detailed reports for transparency.

Professional Metal Stamping Services

As a trusted metal stamping company in China, Yonglihao Machinery has years of experience in manufacturing and design. We provide custom solutions for industries like medical, automotive, and aerospace. Every mold is tailored to customer requirements, and our team’s expertise ensures we meet your unique needs.

Efficient Production:We use advanced automated equipment to support large-volume orders, improving production efficiency.

Cost Effectiveness: By completing multiple steps in a single stamping operation, we reduce labor costs and cycle times, offering a more economical solution.

Precision Machining: Our equipment ensures consistent dimensions and shapes for every part, meeting strict customer requirements.

Wide Range of Applications: Our metal stamping supplies are used in industries like automotive manufacturing, electronics, and household products.

What is Metal Stamping?

Metal stamping is a widely used process that shapes metal sheets into desired forms using presses and molds. It ensures high precision and consistency, integrating operations like shearing and forming to produce complex parts. Techniques include blanking, punching, embossing, and progressive die stamping. These methods can be used individually or combined, depending on the part’s complexity.

This process is ideal for batch production, offering cost-effective and precise solutions for industries like automotive, industrial, lighting, and medical. Yonglihao Machinery provides personalized stamped metal parts using materials like copper, stainless steel, and aluminum. Our competitive pricing, fast delivery, and precision maintenance set us apart. Our project managers ensure a smooth and efficient manufacturing experience.

Advantages and Disadvantages of Custom Metal Stamping

Metal stamping is a precise and efficient method for large-scale production. Below is a summary of its advantages and disadvantages, along with insights from our industry experience:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Production Efficiency | Quickly produces large quantities of identical parts, improving productivity. Automated stamping can double output. | High initial mold costs, with molds accounting for 20% of total costs. |

| Accuracy and Consistency | Ensures high accuracy and consistency, achieving micron-level precision. | Not cost-effective for small-batch production due to high initial costs. |

| Forming Technology | Supports various techniques like punching and embossing, enabling complex designs. | Limited by complex geometric shapes; CNC may be needed for intricate designs. |

| Cost | Low cost for high-volume production, with reduced material waste. | Requires materials with specific properties, limiting options for special materials. |

The advantages make metal stamping manufacturing ideal for large-scale production. However, the disadvantages highlight the need to evaluate batch size and complexity. For small-batch projects, we recommend combining stamping with prototype services. Compared to CNC, stamping is more cost-effective for high volumes but offers less flexibility.

Stamping Types

Yonglihao Machinery offers various stamping types to suit your project needs. Our experts review your 3D models and technical drawings to recommend the best method.

Progressive Die Stamping: Ideal for high-volume production, especially for large parts like automotive components. This method improved efficiency by 20% in one of our projects.

Embossing: Creates 3D designs with raised or recessed surfaces, enhancing aesthetics. We used this for decorative panels in home appliances.

Hydroforming: Uses high-pressure oil to shape metal sheets. It’s fast and accurate, perfect for lightweight aviation parts.

Punching and Fine Blanking: Removes sections from sheets with smooth edges, ideal for electronics.

Bending and Flanging: Forms U, V, or L shapes, suitable for brackets. We optimized this process to reduce deformation risks.

Transfer Die Stamping: Similar to progressive stamping but uses a conveyor belt for continuous production.

Deep Draw Stamping: Creates deep cavity parts like containers, ensuring uniform stretching to avoid cracks.

Four-Slide Stamping: Forms parts on four axes, offering flexibility and cost savings for small, complex parts.

Imprinting: Hardens metal sheets to produce small, round workpieces efficiently.

Punching: Removes material to create precise holes, ensuring accuracy.

FAQ

What is metal stamping?

Metal stamping is a manufacturing process that uses a press and molds to shape metal sheets into specific forms. It involves operations like blanking, punching, embossing, and forming. This process ensures high precision and consistency, making it ideal for large-scale production in industries such as automotive, electronics, and medical.

What are the advantages of metal stamping?

The key advantages of metal stamping include:

- High efficiency: Supports large-scale production and reduces production time.

- High precision: Ensures consistent dimensions and shapes for every part.

- Material efficiency: Minimizes material waste, lowering production costs.

- Flexibility: Allows for custom designs in various shapes and sizes.

These benefits make metal stamping a preferred choice for many industries.

How do I choose the right metal stamping company?

When selecting a metal stamping company, consider the following factors:

- Experience and expertise: Look for companies like Yonglihao Machinery with extensive industry experience.

- Technology and equipment: Ensure the company uses advanced stamping equipment for precision and efficiency.

- Comprehensive services: Choose a company that offers end-to-end solutions, from design to production.

- Customer reviews: Check feedback and case studies to assess reliability and quality.

Which industries use metal stamping?

Metal stamping is widely used across various industries, including:

- Automotive: For engine components, structural parts, and brackets.

- Electronics: For precision components like connectors and casings.

- Medical: For high-precision medical device parts.

- Aerospace: For lightweight, high-strength components.

- Home appliances: For decorative panels, supports, and other parts.

No matter your industry, Yonglihao Machinery provides tailored metal stamping services to meet your needs.

Is metal stamping environmentally friendly?

Yes, metal stamping is an environmentally friendly process. Compared to cutting methods, it reduces material waste and improves material utilization. At Yonglihao Machinery, we follow sustainable manufacturing practices to help our customers achieve their green production goals.

What types of metal stamping does Yonglihao Machinery offer?

We offer a wide range of metal stamping services, including:

- Progressive die stamping: Ideal for high-volume production of large parts.

- Embossing: For decorative and functional 3D designs.

- Deep draw stamping: For creating deep cavity parts like containers.

- Fine blanking: Ensures smooth edges for precision components.

- Four-slide stamping: Suitable for small, complex parts with flexible designs.

Our experts will recommend the best method based on your project requirements.

What materials can be used in metal stamping?

Yonglihao Machinery works with a variety of materials, including:

- Stainless steel

- Aluminum

- Copper

- Other alloys

The choice of material depends on your product’s design, function, and environment. We’ll help you select the most suitable option for your project.

What is the typical lead time for a metal stamping project?

The lead time depends on the complexity of the project and the production volume. Typically:

- Mold design and manufacturing: 2-4 weeks.

- Mass production: Varies based on order size.

We provide a detailed timeline at the start of each project to ensure on-time delivery.

Is metal stamping cost-effective?

Yes, metal stamping is highly cost-effective, especially for large-scale production. While the initial mold cost may be high, it is quickly offset by the reduced per-unit cost in high-volume production. For small-batch projects, we recommend combining stamping with prototyping services to optimize costs.

What makes Yonglihao Machinery’s metal stamping services unique?

As a trusted metal stamping manufacturer, Yonglihao Machinery offers:

- Custom solutions: Tailored molds and processes to meet your specific needs.

- Efficient production: Advanced automated equipment for high-volume orders.

- Strict quality control: Zero-defect production with detailed inspection reports.

- Global standards: All products meet international quality standards.

How do I start a custom metal stamping project?

Starting your project with Yonglihao Machinery is simple:

- Contact us: Share your design drawings or 3D models.

- Requirement analysis: Our team will discuss your needs and recommend the best materials and processes.

- Mold design: We’ll create 3D simulations to ensure feasibility and address potential issues.

- Production and delivery: Using advanced equipment, we’ll produce your parts efficiently and deliver them on time.

No matter the size of your project, we’re committed to providing high-quality metal stamping manufacturing services.