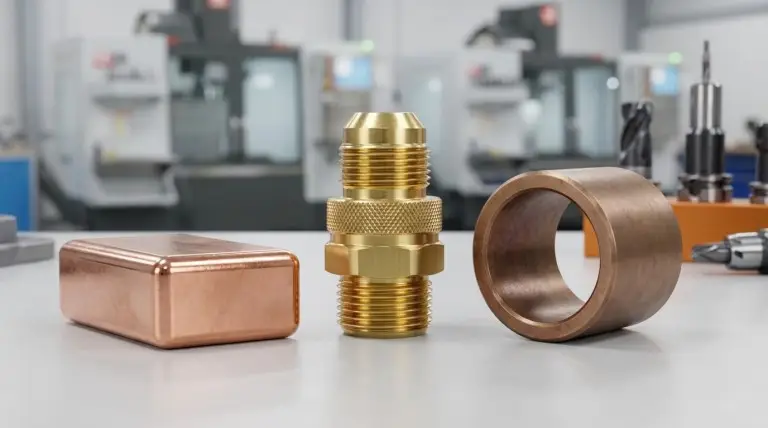

Can precision-engineered components meet the exacting demands of industries like aerospace and automotive? The answer lies in the diverse world of metal fabrication. Here, raw materials are transformed into functional and aesthetic products.

Yonglihao Machinery is renowned for providing high-quality prototype manufacturing solutions thanks to its strong technical capabilities and professional team. We leverage various fabrication techniques to produce items ranging from irrigation pivots to jet engine parts. This showcases the versatility and precision of modern metal fabrication processes.

Exploring the foundation of modern manufacturing reveals the importance of understanding different fabrication processes. Selecting the right technique for specific project requirements is crucial. It ensures optimal results in terms of quality, efficiency, and cost-effectiveness.

Understanding Metal Fabrication: The Foundation of Modern Manufacturing

At its core, metal fabrication involves a range of techniques to shape and assemble metal materials into finished products. This comprehensive process is crucial for various industries. It enables the creation of complex structures and components that power modern society.

Metal fabrication is defined as the implementation of bending, cutting, and assembly to manufacture metal components. It encompasses various techniques, including cutting, bending, assembling, and finishing.

The Evolution of Metal Fabrication Techniques

The story of metal fabrication begins in ancient times when early humans first discovered metals. Initially, simple techniques like hammering were used to shape metals into rudimentary tools and weapons. The Industrial Revolution marked a significant shift in metal fabrication, introducing steam power and mechanization.

Over time, the fundamental principles of metal fabrication have remained consistent. However, technologies and applications have expanded dramatically. This has improved precision, efficiency, and quality.

Understanding the evolution of metal fabrication techniques helps us anticipate future trends. By combining traditional methods with modern computer-controlled processes, we deliver superior metal fabrication solutions. These meet the demands of various industries.

Cutting Processes in Metal Fabrication

In metal fabrication, cutting processes play a vital role in shaping raw materials into finished products. We utilize various cutting technologies to achieve precise dimensions and complex designs, catering to diverse project requirements.

Laser Cutting

Laser cutting is a modern cutting technology. It can cut complex designs with unparalleled precision and produce clean edges. In addition, laser cutting minimizes material waste. This method is ideal for complex projects requiring tight tolerances.

Yonglihao Machinery’s laser cutting services provide outstanding results for sheet metal fabrication projects. They are capable of handling a wide range of materials and thicknesses with exceptional precision.

Plasma and Waterjet Cutting Technologies

Plasma and waterjet cutting are advanced methods in metal fabrication. Plasma cutting works well with thicker materials, offering high speed. Waterjet cutting is better for materials that can’t handle high temperatures. Each method has its own benefits for different materials and projects.

Traditional Cutting Methods

Traditional cutting methods like shearing, sawing, and punching are still useful. They are cost-effective and provide precise cuts. These methods are perfect for projects where advanced technologies aren’t needed.

Choosing a cutting method depends on material type, thickness, edge quality, and production volume. Our team can recommend the best cutting solution for each client. This ensures quality results, no matter the project’s complexity.

Forming and Bending Techniques

Forming and bending are key in metal fabrication. They allow for creating complex shapes from flat metal sheets. These techniques are crucial for making a wide range of metal components without removing material.

Press Brake Forming

Press brake forming is versatile for creating precise bends in sheet metal. It uses specialized tooling and controlled pressure. This ensures accurate bends in various materials and thicknesses. Our advanced press brake equipment guarantees consistent results, making it great for both small and large projects.

Roll Forming Processes

Roll forming is a continuous bending process for making long components with consistent cross-sections. It’s perfect for high-volume production, creating complex shapes quickly and precisely. We use roll forming for projects needing long, uniform metal parts.

Metal Bending Applications and Limitations

Different metal bending techniques have unique applications and limitations. It’s important to understand these to choose the right method for a project. We consider material properties, desired angles, bend radius, and production volume to find the best approach. Proper tooling and setup are key for precise bends and material integrity.

At Yonglihao Machinery, we offer comprehensive metal bending services. Our expertise and advanced equipment ensure high-quality results. Whether it’s press brake forming, roll forming, or other techniques. We meet the highest standards of precision and reliability.

Metal Welding and Joining

In metal fabrication, welding and joining are crucial for durable and strong products. We use various welding processes for the highest quality and precision in our components.

MIG and TIG Welding Techniques

MIG welding is versatile and widely used, suitable for many metals and thicknesses. It balances efficiency and quality, ideal for automotive parts to structural steel. TIG welding is known for its precision, used for thinner materials and intricate shapes. Our team at Yonglihao Machinery is skilled in TIG welding. This ensures superior quality and strength in materials like stainless steel and aluminum.

Arc and Resistance Welding

Arc welding uses an electric arc to melt metals, suitable for heavy-duty jobs. It’s essential for material thickness and strength. We also use resistance welding, joining metals without filler materials, ideal for high-volume production. This method ensures strong and consistent welds, enhancing product quality.

Advanced Joining Methods

We go beyond traditional welding with methods like friction stir welding, laser welding, and adhesive bonding. These advanced techniques cater to various client needs. Our team selects the best method based on material, design, strength, and aesthetics, ensuring top-notch results.

Yonglihao Machinery provides high-quality and high-precision metal welding services. Whether for industrial, automotive, or architectural needs, our metal fabrication expertise delivers robust, reliable products.

Machining Operations in Metal Fabrication

Modern manufacturing demands precision, often achieved through machining. This subtractive process removes material to shape, size, and finish components. It’s crucial for parts with high precision and complex geometries.

We employ advanced machining techniques to produce a wide range of components. Our services include CNC machining, turning, milling, drilling, and wire EDM, each for specific fabrication purposes.

CNC Machining Services

CNC machining is key in modern metal fabrication, offering unmatched precision and repeatability. Computer-controlled machines enable us to create complex components with tight tolerances and exceptional surface finish. Our CNC machining capabilities allow us to work with various metals, producing intricate parts that meet demanding specifications.

Turning, Milling, and Drilling Processes

CNC turning involves rotating the workpiece relative to the cutting tool to form cylindrical parts. This process is ideal for machining shafts, pins, and symmetrical parts. CNC milling uses rotating cutting tools to remove material from stationary workpieces, creating flat surfaces, slots, profiles, and three-dimensional contours with high precision. Drilling is used to create holes in metal workpieces, a fundamental operation in many fabrication projects.

Wire EDM Services

Wire EDM uses electrical discharges to cut conductive materials with extreme precision. It’s particularly valuable for creating complex shapes in hardened materials, where traditional machining is impractical. We use wire EDM to produce components with intricate details and precise dimensions.

| Machining Process | Application | Precision Level |

| CNC Machining | Complex components, intricate parts | High |

| Turning | Cylindrical components, shafts, pins | High |

| Milling | Flat surfaces, slots, profiles, 3D contours | High |

| Drilling | Creating holes in metal workpieces | Medium to High |

| Wire EDM | Complex shapes in hardened materials | Very High |

Yonglihao Machinery’s expertise in machining operations helps us choose the best approach for each project. We consider material properties, geometric complexity, tolerance requirements, and production volume. By combining these capabilities, we deliver high-quality components that meet our clients’ precise needs.

Casting and Molding Processes

Metal fabrication heavily relies on casting and molding to transform molten metal into complex components. These techniques are essential for creating parts with intricate shapes and precise dimensions. They are challenging to produce through other fabrication methods.

Die Casting Services

Die casting is a high-pressure method that creates parts with exact dimensions and fine finishes. It’s perfect for making lots of complex parts. We focus on die casting services, using our skills to make precise components with consistent quality. These parts have great mechanical properties, and we produce them with little waste, saving costs.

Investment Casting Services

Investment casting, or lost wax casting, is a precise method for making intricate parts. It’s great for aerospace and medical fields where complex shapes and high precision are needed. Our investment casting services create complex, near-net-shape parts with minimal machining. This reduces production time and waste.

Sand Casting Applications

Sand casting is a cost-effective, versatile method for making large parts and prototypes. It’s still useful today for creating complex parts of various sizes and shapes. We use sand casting when its benefits are most valuable, ensuring the best outcome for each project.

Our technical knowledge helps us choose the best casting method for each project. Whether it’s die casting, investment casting, or sand casting, we aim to deliver high-quality components. We ensure they meet our clients’ exact needs.

Stamping, Punching, and Forging

Stamping, punching, and forging are key in metal fabrication, creating diverse components. These methods shape metal through controlled deformation. This allows for the production of complex parts with high precision.

Metal Stamping Services

Metal stamping uses specialized dies to form sheet metal into complex shapes in one step. It’s perfect for high-volume production of consistent parts. We offer metal stamping services, producing precision components with complex geometries and tight tolerances.

Our metal stamping capabilities allow for intricate designs and patterns on sheet metal. This makes it versatile for various applications.

Punching Process

Punching operations create holes and cutouts in sheet metal using specialized tooling and presses. Modern CNC-controlled punching equipment enables the creation of complex patterns and features with exceptional accuracy and productivity. This technique is particularly useful for light and bulky metalwork.

We use punching operations to efficiently create precise holes and cutouts in metal. This caters to the needs of various industries.

Forging Techniques and Strengths

Forging is an ancient process that remains relevant for creating components with superior strength and durability. It involves controlled deformation of heated metal. This technique creates a refined grain structure that enhances mechanical properties, making it ideal for components subject to high stress and wear.

We employ forging techniques to produce high-quality metal parts with intricate designs. We leverage the benefits of this traditional process for modern applications.

Industry Applications of Metal Fabrication

The versatility of metal fabrication processes makes them indispensable across various industries, from automotive to consumer goods. At Yonglihao Machinery, we specialize in providing high-quality metal fabrication solutions that cater to the diverse needs of different sectors.

Automotive and Aerospace Applications

Precision-fabricated metal components are crucial in the automotive and aerospace industries, where safety, weight reduction, and performance are paramount. We produce complex components that meet the stringent specifications required for automotive systems and aerospace applications. Our technical expertise ensures compliance with industry standards.

- Precision-engineered parts for automotive and aerospace industries

- Complex component manufacturing for critical applications

- Adherence to stringent industry specifications and standards

Construction and Architectural Uses

Metal fabrication is crucial in modern building design, contributing to both structure and decoration. Our services support the construction industry by offering custom structural components and architectural metalwork. These elements combine functionality with beauty.

- Custom structural components for building frameworks

- Architectural metalwork for decorative and functional purposes

- Integration of metal fabrication in modern construction projects

Consumer Products and Electronics

Precision metal fabrication is key in producing a wide range of consumer products and electronic components. Our team’s extensive experience across industries allows us to apply innovative solutions to each client’s unique challenges.

- Precision fabrication for consumer products and electronics

- Innovative solutions for diverse manufacturing needs

- Application of best practices across various industries

At Yonglihao Machinery, we are dedicated to delivering high-quality metal fabrication solutions. We meet the evolving needs of various industries with our technical strength and professional expertise.

Conclusion

The metal fabrication industry is on the brink of a new era. The techniques we’ve discussed from cutting and forming to welding, and surface finishing. They enhance the versatility and capability of modern manufacturing.

At Yonglihao Machinery, we lead these developments by investing in advanced equipment and technical expertise. Our services include metal stamping, CNC machining, and investment casting. This enables us to handle projects of any type or complexity.

FAQ

What are the most common metal fabrication techniques used in modern manufacturing?

We employ a variety of techniques, including cutting, forming, welding, machining, and surface finishing. Our capabilities include laser cutting, press brake forming, MIG and TIG welding, CNC machining, and powder coating.

How do you determine the best metal material for a specific project?

We consider strength, corrosion resistance, ductility, and cost when selecting a metal material. Our team works closely with clients to understand their needs and recommend the most suitable material.

What is the typical lead time for a metal fabrication project?

Lead times vary based on project complexity, production volume, and material availability. We aim to deliver projects efficiently, usually within a few weeks, while maintaining quality standards.

Can you accommodate custom design requirements and complex geometries?

Yes, we can handle complex designs and custom requirements. Our team uses advanced software to simulate and optimize the fabrication process, ensuring we meet client specifications.

What quality control measures do you have in place?

We have rigorous quality control measures, including inspections during production and final product testing. This ensures our metal components meet required standards.

Do you offer surface finishing and treatment options?

Yes, we provide various surface finishing and treatment options. These include powder coating, painting, plating, and anodizing, to enhance appearance and performance.

Can you handle large-scale production volumes?

We can handle large production volumes while maintaining quality and efficiency. Our equipment and manufacturing systems are designed for high-volume production.