Metal die casting is a fast and efficient manufacturing process. It involves injecting molten metal into a mold under high pressure to produce precise parts quickly. The die casting cycle typically lasts a few seconds to one minute, while the entire project timeline can span weeks or months. This depends on factors like mold creation, prototype production, and production scale. In comparison, low-pressure or gravity casting methods take several minutes per cycle. Understanding the factors that influence die casting time is essential for manufacturers to improve efficiency and cut costs. Key factors include part geometry, wall thickness, cooling time, and mold complexity, all of which directly impact cycle speed. This article explores the stages of die casting, the factors affecting time, and strategies to optimize production for better planning and cost savings.

What is Metal Die Casting?

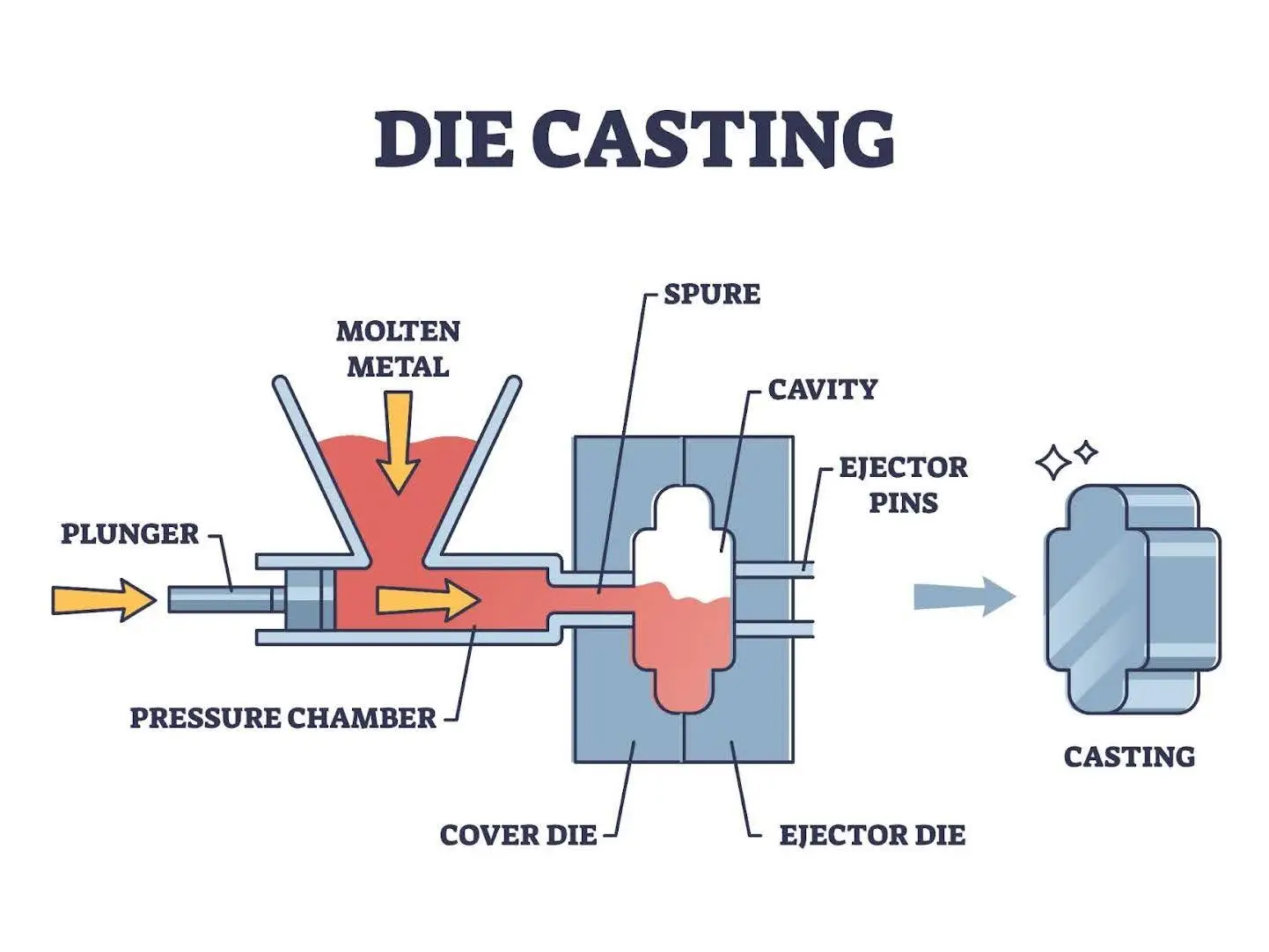

Metal die casting is a process where molten metal is injected into a mold cavity under high pressure. This method produces precise, complex metal parts and is widely used across industries. Its main advantage is speed, with cycles typically lasting only a few seconds to a minute. According to industry data, such as reports from the Die Casting Association, the average cycle time for high-pressure die casting is 15 to 60 seconds. This makes it ideal for high-volume production. For instance, in the automotive industry, die casting is used to create durable, lightweight engine blocks.

The die casting process includes melting the metal, injecting it into the mold, cooling and solidifying it, and finally demolding. Each step affects the final product’s quality. Compared to other casting methods, die casting offers a superior surface finish, reducing the need for additional processing. Choosing the right alloy can further speed up production. For example, zinc alloys, with their low melting points, cool faster.

Die Casting Cycle: Step-by-Step Breakdown

The die casting cycle consists of several key stages that determine production time and quality. Understanding these steps is crucial for optimizing efficiency. While the cycle usually takes a few seconds to a minute, factors like part complexity and mold design can influence the duration. At Yonglihao Machinery, engineers use simulation software to analyze each stage and minimize delays.

Preparation: Mold Readiness

The cycle starts with mold preparation, which includes cleaning, applying lubricants, and preheating to the right temperature. This step ensures consistent quality and prevents defects like bubbles or deformation. Preheating typically takes 1-5 minutes, but automated systems can reduce this to seconds. Proper preheating can also cut cooling time by 10%.

Mold maintenance is critical during this stage. Complex molds take longer to prepare, and factors like mold material and environmental temperature can affect efficiency. Ensuring this step is smooth lays the foundation for the entire cycle.

Injection: High-Speed Pouring

Once the mold is ready, molten metal is injected into it at high speed and pressure. This step determines the fill rate and pressure, which directly impact part quality. Metals like aluminum and zinc, known for their fluidity, allow rapid injection, usually completed in 1-5 seconds. In high-pressure die casting, pressure can reach thousands of PSI to ensure even distribution.

Part geometry influences injection speed. Complex shapes require higher pressure to avoid voids. At Yonglihao Machinery, CFD simulation is used to optimize this stage, reducing scrap rates and improving efficiency.

Solidification and Cooling: The Longest Stage

After injection, the metal solidifies and cools in the mold. This is the most time-consuming stage, accounting for 50-70% of the total cycle time. Cooling time depends on factors like wall thickness and alloy type. Thin-walled parts (2 mm) may cool in 5-10 seconds, while thicker parts take 30 seconds or more.

For example, using water-cooled molds in aluminum die casting can cut cooling time from 20 seconds to 7 seconds. Optimizing this stage is crucial to ensure parts are demolded without damage and to reduce overall cycle time.

Ejection and Reset: Completing the Cycle

Once the metal has solidified, ejector pins push the part out of the mold. This process usually takes 1-4 seconds. Automated robots can reduce this to under 3 seconds, avoiding delays caused by manual operations. Issues like part sticking or pin misalignment can extend this time, but servo-driven systems help maintain efficiency.

After ejection, the mold opens and resets for the next cycle. Efficiency at this stage depends on equipment design. Multi-cavity molds, for instance, can produce multiple parts simultaneously.

Typical Timeline for Die Casting Projects

Die casting projects involve multiple stages, from design to production. The total delivery timeline includes mold manufacturing (4-6 weeks), prototype production (2-4 weeks), and production (weeks or months). Individual part production, however, is measured in seconds. Understanding this timeline helps manufacturers plan budgets and delivery schedules. At Yonglihao Machinery, project management tools ensure transparency and efficiency at every stage.

From Design to First Production Run

This stage includes part design, mold cost assessment, and discussions on customer specifications. Straight parting lines reduce tooling costs, while complex features may require sliding sections, increasing time. Tolerance limits and surface finish are also key considerations.

Design typically takes 1-2 weeks, while mold manufacturing requires 4-6 weeks. Prototype production adds another 2-4 weeks for testing and adjustments. Early simulation analysis can shorten this stage by 15%.

Once the design is finalized, the first production run verifies quality standards. Decisions made here impact the efficiency of subsequent production.

Production Scaling and Optimization

After the first run, the focus shifts to scaling and optimization. This includes adjusting machine parameters, cooling systems, and part handling. Data analysis identifies bottlenecks, such as cooling delays, and implements improvements. Continuous monitoring ensures consistency.

Decisions made during the design stage, like selecting scalable molds, simplify this process. At Yonglihao Machinery, real-time monitoring software has increased output by 20%.

Production timelines depend on order size. Small batches can be completed in weeks, while large orders may take months. The total project timeline balances speed and quality.

How Long Does Die Casting Take: Cycle Time Analysis

Die casting cycle time is a critical factor in production efficiency and varies depending on the method used. High-pressure die casting (HPDC) is known for its short cycles, making it ideal for large-scale production. In contrast, low-pressure die casting (LPDC) takes longer but often delivers higher quality. Understanding these differences helps manufacturers choose the right method for their needs.

High-Pressure Die Casting Time

High-pressure die casting is celebrated for its speed, with cycle times ranging from a few seconds to a minute. This speed is due to the high pressure, which allows for rapid metal filling and solidification. Factors like wall thickness and cooling setup also influence the time. Efficient cooling systems can further reduce cycle times. According to industry data, HPDC productivity can be twice as high as LPDC, making it a preferred choice for high-volume production.

Low-Pressure Die Casting Time

Low-pressure die casting, on the other hand, has longer cycle times, typically ranging from 1 to 2 minutes. This is due to slower fill rates and different pressure profiles. However, LPDC offers advantages like fewer defects and lower porosity, making it suitable for applications where quality is a priority.

By comparing HPDC and LPDC, manufacturers can make informed decisions based on production volume, cost, and specific application needs.

Factors Affecting Die Casting Time

Several factors influence die casting cycle time, including material choice, design complexity, and machine settings. Understanding these elements is essential for optimizing efficiency and reducing costs.

Alloy Choice

The type of alloy used significantly impacts die casting time. Alloys with lower melting points, like zinc, cool faster and have shorter cycle times compared to aluminum. Thermal conductivity and solidification rates also play a role. For each project, we analyze alloy requirements to determine the best casting conditions.

Die Design and Complexity

The complexity of the die directly affects cycle time. Intricate designs with multiple cavities or features take longer to fill and eject. Simplifying die designs, where possible, can reduce production time without compromising quality.

Machine Specifications and Settings

Machine capabilities and settings are also critical. High-pressure machines produce parts faster but require more complex dies. Adjusting parameters like injection speed and pressure can optimize cycle times. At Yonglihao Machinery, experienced technicians ensure machines are calibrated for peak performance.

Part Size and Wall Thickness

Part size and wall thickness are key factors, especially during the cooling phase. Thin walls (2-3 mm) solidify in 5-7 seconds, while thicker sections (8-12 mm) may take 20-30 seconds or more. Advanced cooling techniques, like water-cooled dies, help minimize cooling times.

| Wall Thickness (mm) | Cooling Time (seconds) |

|---|---|

| 2-3 | 5-7 |

| 5-8 | 10-15 |

| 8-12 | 20-30 |

Die Casting vs. Other Casting Methods: Time Comparison

Die casting stands out for its speed and precision, but how does it compare to other casting methods? This section explores the time differences between die casting and other techniques, helping manufacturers choose the best process for their needs.

Die Casting vs. Sand Casting Time

Die casting and sand casting differ significantly in production timelines. Die casting is ideal for high-accuracy projects, with cycle times ranging from 15 to 60 seconds. Sand casting, while more flexible in size and material, is slower due to its manual processes. Production times can range from several hours to days.

| Casting Method | Cycle Time | Production Volume |

|---|---|---|

| Die Casting | 15-60 seconds | High |

| Sand Casting | Several hours to days | Low to Medium |

Die Casting vs. Investment Casting Time

Investment casting, or lost-wax casting, involves multiple time-intensive steps like pattern making and shell building. This results in production times measured in days rather than seconds. While investment casting offers greater precision and design freedom, die casting is much faster.

The choice between these methods depends on factors like production volume, part complexity, and time constraints. Die casting excels in speed and efficiency, making it ideal for high-volume production of complex parts. However, other methods may be better suited for specific requirements like surface finish or material flexibility.

Further Reading:Investment Casting vs Die Casting:Which Is Suitable for Your Application?

Strategies to Optimize Die Casting Cycle Time

Die casting cycle time can be significantly reduced through strategic optimizations in die design, process parameters, and cooling methods. These strategies are essential for improving efficiency and cutting production costs.

Die Design Optimization Techniques

Die design plays a major role in cycle time. Techniques like optimizing wall thickness, using draft angles, and designing efficient gating systems can make a big difference.

| Optimization Technique | Impact on Cycle Time | Example |

|---|---|---|

| Wall Thickness Optimization | Reduces cooling time | 2.5 mm walls: 7-second cooling time |

| Gating System Design | Improves material flow | Streamlined gating reduces turbulence |

| Draft Angles | Eases part ejection | Reduces ejection force by 30% |

Process Parameter Adjustments

Fine-tuning process parameters like injection pressure, temperature, and cycle timing can also optimize cycle time. These adjustments ensure faster production without compromising quality.

- High-pressure die casting enables rapid cycles through fast injection.

- Optimized temperature control prevents overheating and ensures consistent solidification.

- Precise cycle timing reduces waste and improves efficiency. In one project, automated adjustments increased output by 15%.

Advanced Cooling Methods

Advanced cooling techniques can dramatically reduce cycle times by speeding up solidification. Using copper inserts, high-efficiency cooling systems, and thermal management materials enhances cooling efficiency.

Conclusion

The success of die casting projects depends on balancing production time with part quality and integrity. This article has explored the factors that influence die casting time, from alloy choice and die design to machine settings and cooling techniques. Understanding these elements is key to effective production planning, cost estimation, and maintaining competitive operations.

By optimizing each phase of the custom die casting process—preparation, injection, cooling, and ejection—manufacturers can significantly reduce cycle times without sacrificing quality. At Yonglihao Machinery, we specialize in aluminum and zinc die casting and are committed to helping customers achieve the perfect balance of speed, quality, and cost. With our expertise, manufacturers can ensure their die casting operations are both efficient and effective.

FAQ

What is the Typical Cycle Time for High-Pressure Die Casting?

High-pressure die casting cycles typically range from a few seconds to several minutes, depending on part complexity, material, and machine specifications. For example, zinc applications can take as little as 4 seconds per cycle. Simulation tools are recommended for accurate predictions.

How Does the Choice of Alloy Affect Die Casting Time?

Alloys with lower melting points, like zinc, generally have shorter cycle times compared to higher-melting-point alloys like aluminum. Fluidity and solidification rates also influence the process.

What Factors Influence the Die Casting Cycle Time?

Key factors include die design, machine settings, part size, wall thickness, and material choice. Optimizing these elements can reduce cycle time and improve efficiency. For instance, advanced machines can offset the impact of thicker walls, which may extend cooling time by 20 seconds.

How Does Die Design Impact Die Casting Time?

A well-designed die with efficient gating, venting, and cooling systems can significantly reduce cycle time. Complex designs, however, may increase production time. Early optimization avoids delays and ensures smooth operations.

What is the Difference in Cycle Time Between Die Casting and Sand Casting?

Die casting is much faster, with cycle times of 15-60 seconds, compared to sand casting, which can take hours or days. Die casting’s high-pressure efficiency contrasts with the manual steps involved in sand casting.

Can Die Casting Cycle Time Be Optimized?

Yes, through strategies like die design optimization, process parameter adjustments, and advanced cooling methods. These improvements can reduce cycle time and enhance overall efficiency.

What Are the Typical Cycle Times for Aluminum and Zinc Die Casting?

Aluminum die casting cycles range from 30 seconds to several minutes, depending on part complexity. Zinc die casting is faster, with cycles typically lasting 15-60 seconds due to its low melting point.