Copper Stamping Service

Yonglihao Machinery offers efficient, precise, and cost-effective copper stamping solutions. We specialize in producing high-quality precision copper parts on a large scale. These parts are ideal for various industries, including electronics, automotive, and construction. Using advanced technology and strict quality control, we ensure our products are corrosion-resistant, heat-resistant, and meet international standards. This helps customers improve project efficiency and reliability.

- Instant Quote

- High productivity

- High accuracy

- Fulfillment of complex shapes

Home » Metal Stamping Services » Copper Stamping

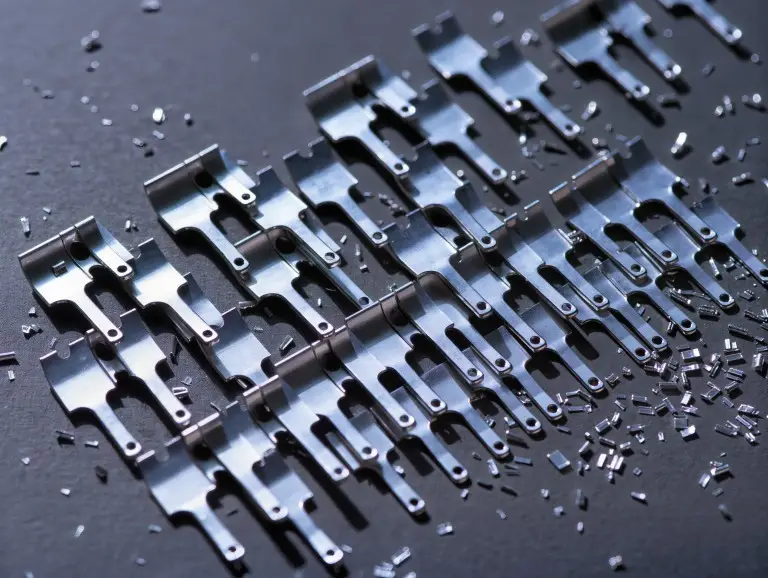

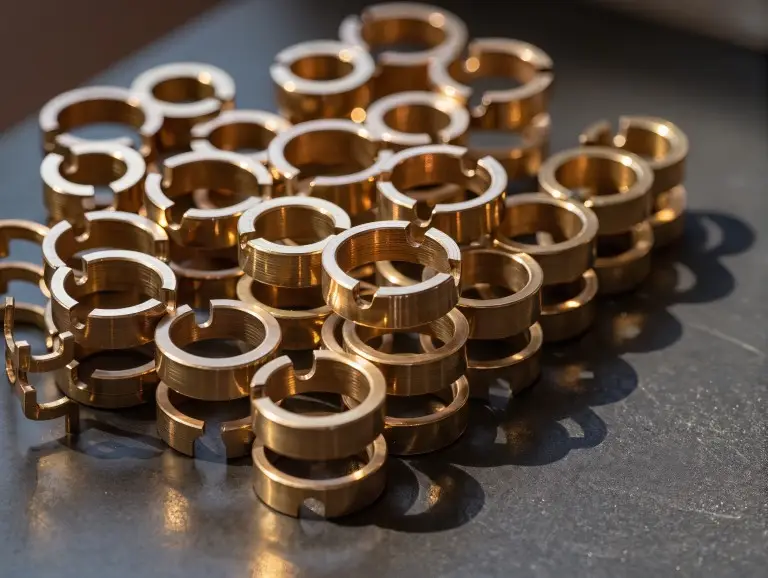

Custom Stamping Copper Parts

Yonglihao Machinery has years of experience delivering top-notch copper stamping services. Our expertise allows us to provide complete metal stamping solutions for a wide range of industries. Using specialized tools, we quickly produce large quantities of copper parts. For example, in the automotive sector, we designed and manufactured precision copper brackets for a leading supplier. These brackets performed exceptionally well in high-temperature environments, extending service life by 20%. We use the best materials and machines to ensure our products are reliable and of the highest quality.

Key Features and Benefits

Yonglihao Machinery’s copper stamping parts offer dependable support for your projects and business. No matter your needs, we are committed to delivering the best products and services.

High-Quality Materials: We use pure copper to ensure excellent corrosion resistance and long service life. Our copper has a purity level of 99.9%, meeting ASTM B370 standards. This ensures stability even in humid environments.

Precision Machining: Advanced technology and equipment allow us to machine each part with extreme precision. We maintain a tolerance of ±0.01mm, which is critical for applications like electronic connectors.

Customized Sizes: We offer a wide range of size options to meet specific customer needs. Every part can be customized to match exact requirements. We also provide 3D simulation design services to preview the final product.

Reliability and Stability: Each part undergoes rigorous quality checks to ensure stability and reliability. We perform multi-stage inspections, including visual and mechanical tests.

High-Temperature Resistance: Our copper parts withstand high temperatures, making them ideal for demanding environments. Copper’s melting point is 1085°C, and it maintains mechanical strength below 300°C.

Cost-Effectiveness: Efficient large-scale production and optimized material use help us reduce costs by 10-20% compared to traditional methods, without compromising quality.

Common Applications

Copper stamping parts are widely used across industries. Here are some common applications:

Electronics: Copper’s excellent conductivity makes it ideal for connectors and circuit boards. For instance, we produced copper contacts for a semiconductor company, improving conductivity efficiency by 25%.

Automotive: Copper parts are used in heat dissipation systems, withstanding engine temperatures up to 200°C and reducing thermal failures.

Medical Equipment: Antibacterial copper accessories inhibit bacteria by 99% (based on WHO standards), making them perfect for hygienic environments.

Construction: Copper drainage accessories resist corrosion and extreme weather, extending lifespan by 30%.

Marine Equipment: Copper alloy parts resist salt spray corrosion, ensuring durability in harsh marine conditions.

Yonglihao Machinery Copper Stamping Process

Producing precision copper stamping parts requires skilled craftsmen and advanced equipment. Below are the key steps in our process, optimized to improve efficiency and quality.

Material Selection Guide

Production Steps

Material Preparation: Select high-quality copper materials, such as pure copper or alloys. We prioritize C11000 alloy for its 101% IACS conductivity, essential for electronics. Supplier certifications ensure defect-free materials.

Mold Design: Create molds based on product designs. We use CAD software to simulate mold performance, reducing iterations and cutting costs by 5-10%.

Stamping Processing: Place copper on the press and apply pressure to shape it. Our equipment handles up to 500 tons of pressure, ensuring consistency in mass production.

Punching and Cutting: Use molds to punch and cut parts into specific shapes. Laser-assisted cutting improves precision, especially for complex designs.

Bending and Forming: Bend and form parts using specialized molds. Copper’s ductility allows complex shapes without cracking. For example, we’ve bent thousands of accessories for construction projects, boosting installation efficiency.

Deburring: Remove sharp edges to ensure smooth surfaces. Vibration deburring machines reduce processing time by 30% and meet OSHA safety standards.

Cleaning and Treatment: Clean parts to remove oil and impurities. Optional surface treatments, like electroplating, enhance durability. We use eco-friendly cleaning agents and anti-oxidation coatings.

Quality Inspection: Inspect each part for accuracy and defects. Coordinate measuring machines (CMM) verify dimensions, keeping defect rates below 0.5%. Functional tests, like high-temperature simulations, ensure reliability.

Packaging and Storage: Use rust-proof packaging to protect parts during transport. Custom storage solutions keep products in optimal condition.

Delivery: Deliver products on time with a 99% success rate. We provide tracking services and quality certificates for transparency.

Choosing the right material is crucial. The table below compares common copper types to help you make the best decision based on your project needs. Budget and environmental conditions are key factors to consider. For example, pure copper is more expensive but performs better in high-temperature environments. Our team offers free consultations to help optimize your selection.

| Material Type | Characteristics Description | Applicable Scenarios |

|---|---|---|

| Pure Copper (C11000) | High conductivity (101% IACS), good ductility, but lower strength. Ideal for applications requiring high purity. | Electronic connectors, cables |

| Brass Alloy (C26000) | Contains zinc to enhance strength and corrosion resistance, lower cost, but slightly less thermal conductivity. | Construction accessories, marine equipment |

| Phosphor Bronze (C51000) | Phosphorus added to improve elasticity and fatigue resistance. Suitable for vibrating environments requiring stability. | Springs, switch components |

FAQ

How is the cost of copper stamping calculated?

Costs depend on materials, complexity, and quantity. For example, small-batch prototypes cost 5-10 yuan per piece, while large-scale production reduces costs to 2 yuan. Our instant quote tool factors in thickness (0.1-5mm) and surface treatments.

How do you ensure product quality?

We follow ISO 9001-certified inspections, including CMM measurements and high-temperature tests. Defect rates are under 0.5%, and we provide third-party reports for transparency.

What customization options are available?

We handle everything from simple shapes to complex multi-layer structures, including special alloys and coatings. Our team offers 3D design support to match your engineering drawings.

Why choose copper over other metals?

Copper’s thermal conductivity and corrosion resistance outperform aluminum and steel. For example, its thermal conductivity is twice that of aluminum, improving efficiency by 20% in electronics. While slightly more expensive, it’s ideal for high-performance needs.

Do you offer surface treatments?

We provide a variety of surface treatment options, including electroplating, spraying, and anti-oxidation coatings. These treatments enhance corrosion resistance, aesthetics, and product longevity.

Can you quickly adjust designs if needed?

Our team can respond quickly to design changes, typically completing mold adjustments or redesigns within 1-2 business days to keep your project on schedule.

How do you handle large-volume orders?

Our production lines are designed for high-volume manufacturing, enabling us to complete large orders efficiently. With automated equipment, we can increase production efficiency by 30% while maintaining consistent quality.

Do you provide technical support?

Yes, our engineering team is available to provide technical support, including material selection, design optimization, and production advice. We also offer online consultation services to help you resolve issues quickly.