Chromate Conversion Coating Services

Yonglihao Machinery offers Chromate Conversion Coating Services for aluminum parts, providing practical protection and reliable downstream performance. This conversion film is extremely thin, enhancing corrosion resistance and coating adhesion without adding significant thickness like heavier finishes.

- Aluminum-specific pretreatment

- Conductive contact surfaces

- Paint-ready conversion layer

- Masking for critical features

Home » Surface Finishing Service » Chromate Conversion Coating Services

What Is Chromate Conversion Coating?

Chromate conversion coating is a chemical process that forms a thin film on aluminum surfaces. It acts as a functional “base layer,” enhancing corrosion resistance and paint/powder adhesion while often maintaining good electrical contact performance for assembly interfaces.

Since the film is so thin, the final result depends heavily on the initial surface condition and the chosen preparation method.

I primarily apply chromate conversion coating to aluminum and aluminum alloys, including:

5052, 6061, 6063, 7075, 2024, and other grades upon review.

If you’re unsure about your alloy or temper, send your drawing and material details. I’ll confirm compatibility before processing.

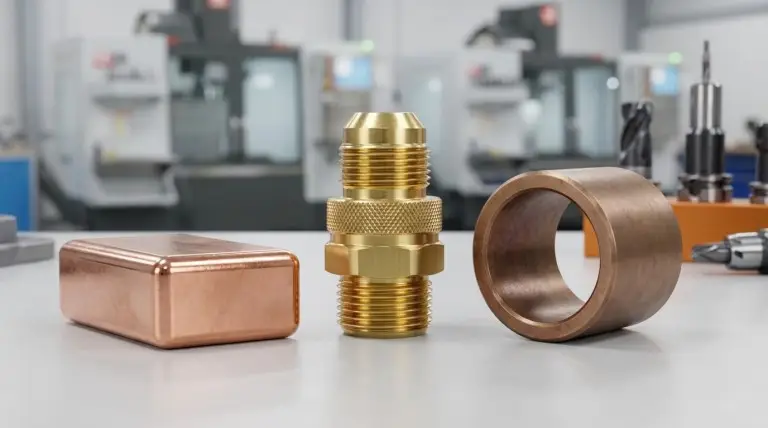

One-Stop Manufacturing

For seamless production, Yonglihao Machinery offer these manufacturing processes with chromate conversion coating as a downstream step:

Surface Preparation & Final Appearance

Surface preparation significantly affects the final appearance. The conversion coating is extremely thin, so it does not hide surface defects.

Machining marks will remain visible after coating. For a cleaner, more uniform look, bead blasting can reduce or remove these marks, depending on your cosmetic goals. If a “cosmetic” finish is required, confirm it early. Common expectations include a matte/foggy look, reduced tool marks, and an agreed color range.

Note: Conversion coating cannot cover scratches, dents, or deep surface damage. The base metal condition and preparation method determine the final appearance.

| Surface preparation | Base metal | Appearance (color) | Film thickness* | Approval/notes |

|---|---|---|---|---|

| As machined | Aluminum alloy | Clear to light yellow/gold | 0.25–1.0 μm | Ultra-thin film; minimal dimensional change. Approve by appearance, coverage, or test results. Color varies by alloy and chemistry. |

*Film thickness depends on process and requirements. For cosmetic-critical parts, confirm with a sample or witness coupon.

FAQ

What materials does chromate conversion coating work on?

Mainly aluminum and aluminum alloys. Share your grade, temper, and application for confirmation.

Is the surface conductive after conversion coating?

Yes, it often maintains good electrical contact performance. Define your requirement if contact resistance is critical.

Can I paint or powder coat over the conversion coating?

Yes, it’s commonly used to improve adhesion and ensure stable downstream coating performance.

Will machining marks still be visible after coating?

Yes, the film is very thin. Discuss bead blasting or other prep methods if cosmetics are important.

Can conversion coating hide scratches or dents?

No, surface defects like scratches and dents remain visible. The base condition determines the appearance.

Will it change part dimensions or fits?

It adds minimal thickness and is often treated as “no thickness increase.” For tight fits, define acceptance criteria on the drawing.

Can you mask threads, seal faces, and critical contact surfaces?

Yes, mark these areas on your drawing or include them in your RFQ notes.

What do you need for a fast quote?

Material grade, quantity, part size, cosmetic target, paint/powder steps, critical surfaces, and lead time.