Black Oxide Services

Yonglihao Machinery offers black oxide finishing to create a clean, black, low-glare surface with minimal impact on dimensions. This chemical conversion finish is commonly used for steel parts that require a uniform black appearance and improved handling.

- Matte black look with reduced glare

- Ultra-thin layer that preserves fits

- Cost-effective for fast production parts

Home » Surface Finishing Service » Black Oxide Services

What Is Black Oxide?

Black oxide is a chemical process that converts the metal surface into a dark oxide layer. On ferrous metals, it forms black iron oxide (magnetite, Fe₃O₄), resulting in a uniform black finish with minimal thickness.

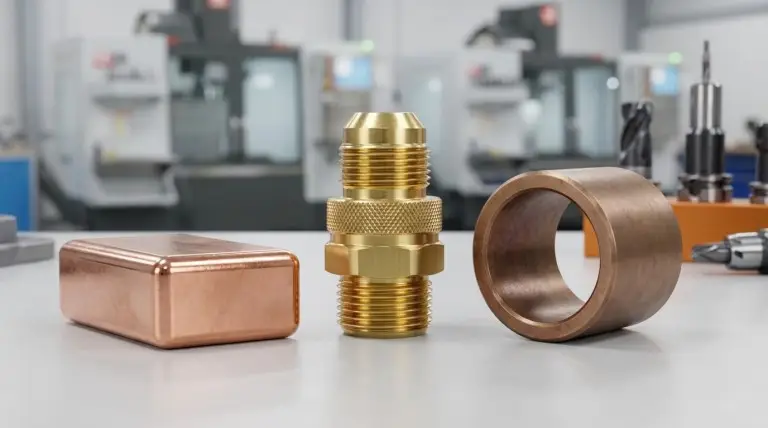

It is most commonly applied to steel and corrosion-resistant steels. Blackening processes are also available for stainless steel and copper/copper alloys, but these require specific chemistry and should be confirmed during the RFQ stage.

One-Stop Manufacturing

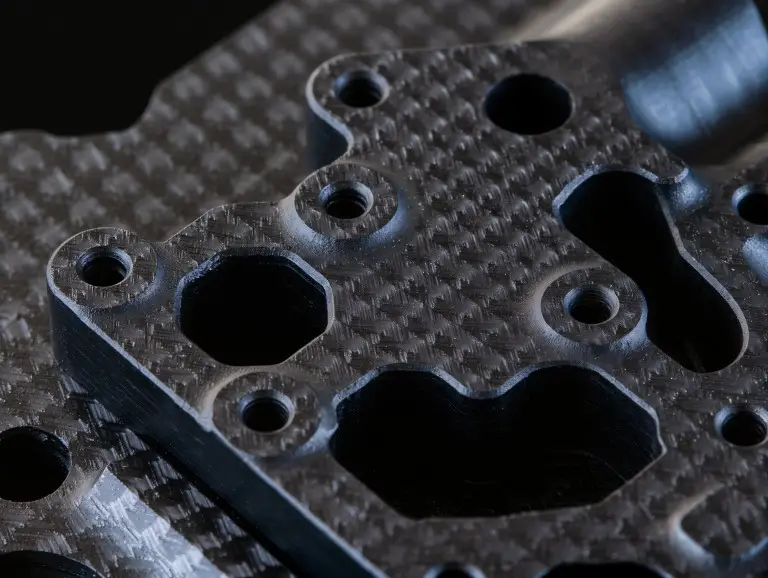

We can apply black oxide as a finishing step for parts made through:

Surface Preparation & Final Appearance

Black oxide is a conversion finish, meaning it does not cover up scratches, dents, pits, or machining marks. The final appearance depends heavily on the base surface condition and cleaning quality.

- Thickness: Typically 0.5–2.5 μm, depending on the process.

- Corrosion Resistance: Often paired with a seal (oil or wax) for added protection.

| Surface Preparation | Color | Applicable Materials | Typical Thickness | Visual Appearance |

|---|---|---|---|---|

| As-machined (Ra 3.2 μm / 126 μin) | Black | Steel, stainless steel (process-dependent), copper/copper alloys | ~0.5–2.5 μm | Smooth to matte black (surface-dependent) |

FAQ

What materials can be blackened?

Black oxide works best on steel and corrosion-resistant steels. Stainless steel and copper can also be blackened with substrate-specific processes (confirm by grade).

Will it change part dimensions?

No, it’s an ultra-thin finish and is usually considered negligible for most fits.

Does black oxide prevent rust?

It offers limited corrosion protection on its own. Adding a seal (oil or wax) significantly improves resistance.

Will machining marks still show?

Yes, black oxide follows the existing surface and does not hide tool marks or scratches.

Can threads, seal faces, and critical areas be masked?

Yes, simply mark no-finish zones clearly on the drawing or RFQ notes.

Can black oxide be specified to a standard?

Yes, requirements like MIL-DTL-13924 or AMS 2485 can be specified in your RFQ to align the process with your needs.