As Machined Services

Yonglihao Machinery offers As Machined services for parts requiring a clean, functional surface without additional finishing steps. This approach keeps your part in its “straight off the machine” condition, ensuring fast turnaround, stable fits, and predictable costs.

- Fastest lead time: No extra coating or polishing steps.

- No added thickness: Maintains stable fits and dimensions.

- Cost-efficient: Perfect for prototypes and functional parts.

- Tool-mark transparency: Simplifies inspection of features and machining quality.

Home » Surface Finishing Service » As Machined Services

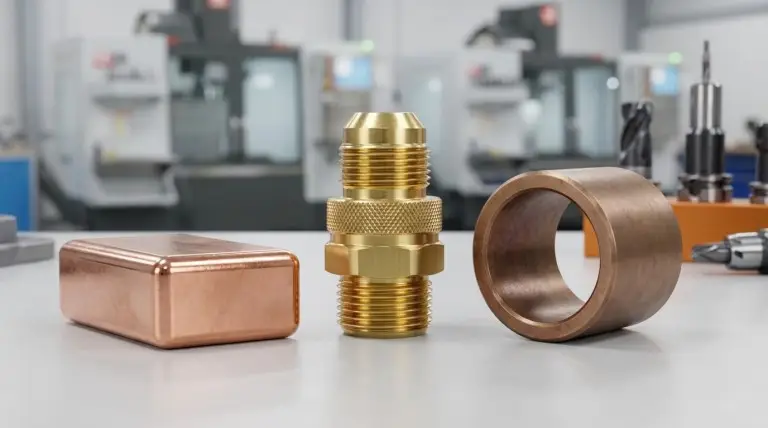

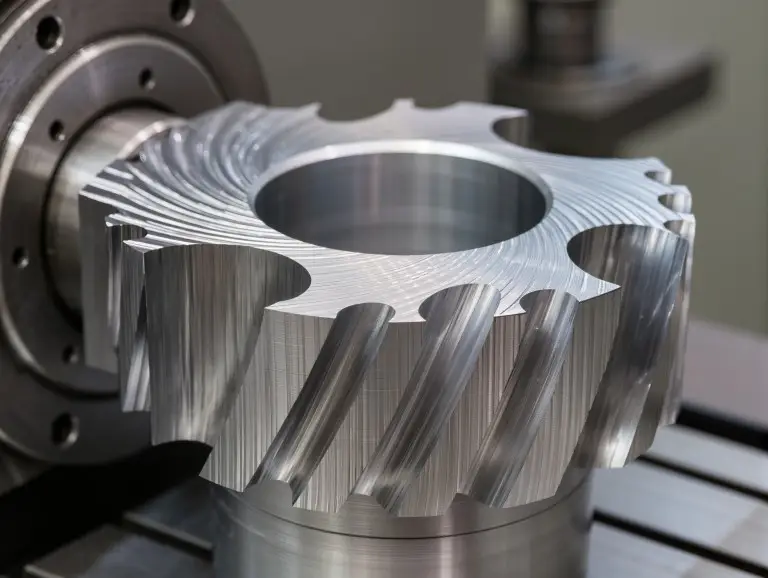

What Is As Machined?

“As machined” means the part is delivered in its original machined surface condition, without extra finishing like anodizing, plating, blasting, or polishing. Expect visible tool paths, light milling or turning lines, and natural surface variations based on tool access and cutting direction.

For most CNC builds, we use Ra 3.2 μm (Ra 126 μin) as the standard baseline for “as machined” surfaces. If your part requires smoother contact faces or cosmetic panels, specify a tighter Ra requirement upfront.

One-Stop Manufacturing

We support As Machined surface condition across our in-house processes, including:

Surface Preparation & Final Appearance

“As machined” surfaces will not hide scratches, dents, welding marks, or casting imperfections. Any marks created during machining, especially on flat faces or around tool entry and exit points, will remain visible.

For a cleaner look while staying “non-coated,” we can provide deburring, edge breaking, or targeted surface smoothing on functional faces, as specified in your drawing notes.

| Surface Roughness (Typical) | Applicable Materials | Cosmetic Availability | Visual Appearance | Application Scenarios |

|---|---|---|---|---|

| Ra 3.2 μm / Ra 126 μin | Metals, plastics | Functional (not cosmetic) | Visible tool marks; natural machining texture | Mechanical parts, lab equipment, R&D prototypes |

FAQ

Is “as machined” the same as “no finish”?

Yes. No coating or polishing is applied. You receive the original machined surface condition.

Will tool marks be visible?

Yes. Tool marks are normal for as machined surfaces, especially on milled faces.

Does “as machined” affect dimensions or fits?

No. Since no coating is added, dimensions and fits remain stable.

Can you deburr edges and remove sharp corners?

Yes. Include edge-break or deburr notes in your drawing or RFQ.

Can I specify a smoother Ra than 3.2 μm?

Yes. Define the target Ra and critical faces, and we’ll confirm feasibility based on material and geometry.