Bead Blasting Services

Yonglihao Machinery offers bead blasting services to clean metal surfaces and create a uniform matte texture. This process reduces glare, softens visible tool marks, and improves coating consistency before anodizing, painting, or powder coating.

- Creates a uniform matte or satin finish

- Removes light oxidation and surface contamination

- Reduces visible machining lines for cosmetic improvement

- Enhances consistency for downstream coatings

Home » Surface Finishing Service » Bead Blasting Services

What Is Bead Blasting?

Bead blasting is a surface preparation method where fine media—typically glass beads—are propelled onto a part. This process removes light oxidation and contamination while creating a controlled matte texture with minimal material removal.

The final appearance depends on the base material, the initial surface condition, and the chosen bead size and pressure.

One-Stop Manufacturing

We integrate bead blasting as a downstream step for parts produced through:

Surface Preparation & Final Appearance

Bead blasting does not fix deep scratches, dents, pits, or heavy weld spatter. These defects may still be visible after blasting, though they will appear less reflective.

If cosmetic quality is critical, define your requirements early. Specify the desired matte level, uniformity, and acceptable variations, or approve a sample to ensure expectations are met.

| Typical Spec Item | Applicable Materials | Media (Example) | Texture / Appearance | Service Coverage |

|---|---|---|---|---|

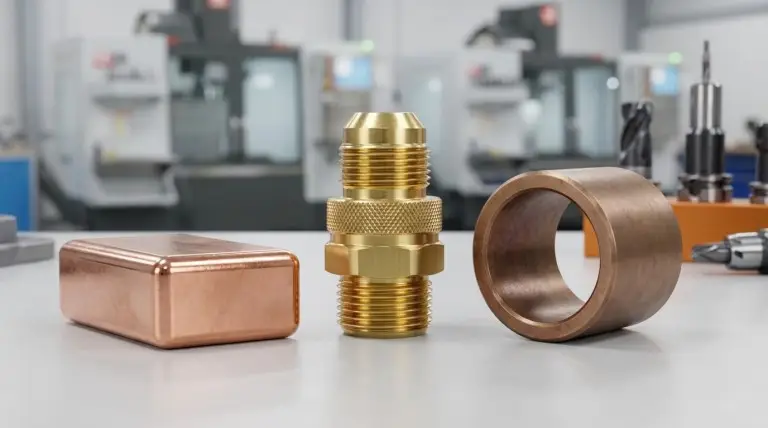

| Media size + texture target | Aluminum, stainless steel, carbon steel, titanium, brass, copper, tool steel (review if thin-wall) | Glass beads 120 mesh (or equivalent) | Matte / satin, non-glare | CNC machining, metal stamping, investment casting, die casting, welding, laser cutting, bending |

FAQ

What materials does bead blasting work on?

Bead blasting is commonly used on aluminum, stainless steel, carbon steel, titanium, brass, copper, and tool steels. Thin-wall parts are reviewed to prevent distortion.

Does bead blasting remove scratches or dents?

It reduces the visibility of light marks, but deep scratches, dents, pits, and weld defects will remain visible.

Will bead blasting change part dimensions or fits?

Material removal is minimal. However, tight-tolerance bores, threads, and sealing faces should be masked to maintain precision.

What surface texture will I get?

The process typically produces a matte or satin, non-glare finish. The exact texture depends on the base material, initial surface condition, and bead size/pressure.

Is bead blasting good before anodizing or painting?

Yes, it helps create a more uniform appearance and improves consistency for downstream coatings.

Do you follow Sa1 / Sa2 / Sa2.5 / Sa3 standards?

These standards are primarily for steel rust-removal classification. For bead blasting, we control results using media size, pressure, coverage, and the agreed texture target.

Can you mask threads, seal faces, engraving, or contact pads?

Yes, we can. Clearly mark “no-blast” zones on the drawing or include them in RFQ notes.

What do you need for a fast quote?

Provide details such as material, quantity, part size, target texture (matte/satin), cosmetic priority, masking areas, downstream coating requirements, and lead time.