Anodizing Services

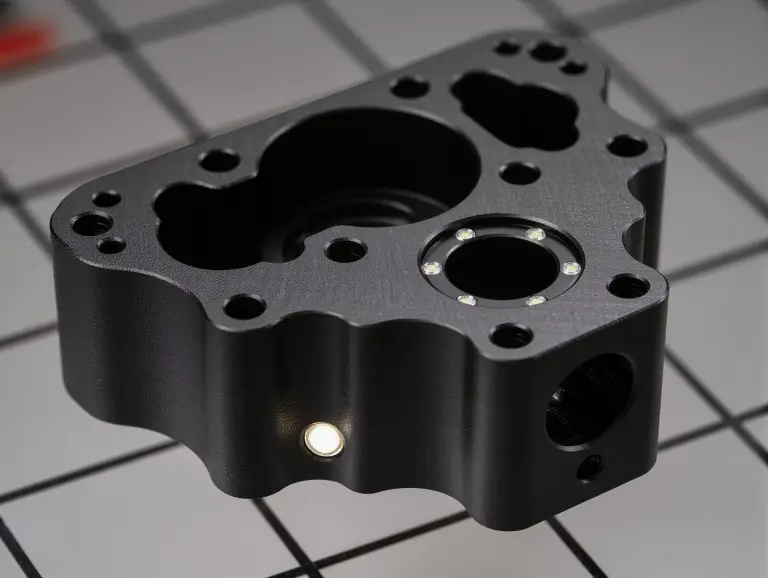

Yonglihao Machinery provides anodizing services for aluminum parts. This process creates a controlled oxide layer that enhances corrosion resistance, improves wear performance, and supports downstream finishing—all without altering part geometry like heavy coatings do.

- Type II anodizing: corrosion protection + color options

- Type III hardcoat: higher wear resistance for contact zones

- Finish control: clear/black/dyed results (alloy-dependent)

- Masking support: threads, seal faces, pads, and critical fits

Home » Surface Finishing Service » Anodizing Services

What Is Anodizing?

Anodizing is an electrochemical process that transforms the aluminum surface into aluminum oxide. This oxide layer grows directly from the base metal, forming a strong bond that resists peeling under normal conditions.

- Type II: Focuses on corrosion protection and appearance. It also serves as a solid base for paint or adhesives.

- Type III (Hardcoat): Creates a thicker, denser oxide layer for better performance in abrasive, high-contact, or frequently handled applications.

We anodize aluminum and its alloys, including 5052, 6061, 6063, 7075, and 2024 (upon review). If you’re unsure about the grade or temper, send us your drawing and material specifications. We’ll confirm compatibility, especially for color consistency or tight tolerances.

Final color and uniformity depend on factors like alloy chemistry, surface prep, racking method, and part geometry. For cosmetic-critical parts, we recommend defining a clear visual target early or approving a sample.

| Item | Type II Anodizing | Type III Anodizing (Hardcoat) |

|---|---|---|

| Materials | Aluminum | Aluminum |

| Color | Clear + dyed colors (e.g., black, blue) | Clear to dark grey/black (alloy-dependent) |

| Texture | Smooth or matte (prep-dependent) | Smooth or matte (prep-dependent) |

| Typical Thickness | 5–25 μm (0.0002–0.0010 in) | 25–125 μm (0.001–0.005 in) |

| Best Use | General corrosion protection + aesthetics | Wear resistance for high-contact areas |

| Common Applications | Construction, electronics, industrial parts | Aerospace, automotive, sliding/wear parts |

Note: Thickness, color, and surface texture vary based on alloy, geometry, and coating build. Define acceptance criteria on drawings for cosmetic or fit-critical parts.

One-Stop Manufacturing

Yonglihao Machinery integrates anodizing as a downstream step after:

Surface Preparation & Final Appearance

Anodizing follows the existing surface and does not hide scratches, dents, casting pits, or deep tool marks. For cosmetic parts, surface preparation is as important as the anodizing type.

- As-Machined: Tool marks remain visible, especially under clear anodizing. Best for functional parts or tight-fit areas.

- Bead-Blasted: Creates a uniform matte finish, reducing visible lines and glare.

- Brushed: Produces a controlled directional finish, ideal for panels or covers.

Color variation is common across different alloys, weld zones, and mixed material lots. Even within the same alloy, thickness and geometry can cause shade differences. For cosmetic-critical parts, align expectations with a sample or witness coupon before full production.

| Surface Prep | Base Metal | Appearance | Notes |

|---|---|---|---|

| As-Machined | Aluminum alloy | Tool marks visible; streaking possible | Best for functional parts and tight fits |

| Bead-Blasted | Aluminum alloy | Uniform matte | Reduces cosmetic variation and glare |

FAQ

What materials does anodizing work on?

Primarily aluminum and its alloys. Share the grade and temper to confirm compatibility.

Is anodizing good for corrosion resistance?

Yes. Type II is commonly used for corrosion protection and appearance.

Is Type III stronger than Type II?

Yes. Type III is thicker and more wear-resistant, ideal for contact or abrasion zones.

Can I get colored anodizing?

Yes, typically with Type II. Dye color and consistency depend on alloy and surface prep.

Will machining marks still be visible?

Yes. Bead blasting can help if cosmetics are important.

Does anodizing affect dimensions or fits?

Yes. Define thickness, fit-critical areas, and acceptance criteria on the drawing.

Is the surface electrically conductive after anodizing?

No. The oxide layer is insulating. Leave bare pads if conductivity is required.

Can you mask threads, seal faces, and contact areas?

Yes. Mark these areas on the drawing or include them in RFQ notes.